ITM | Integrated Test + Measurement

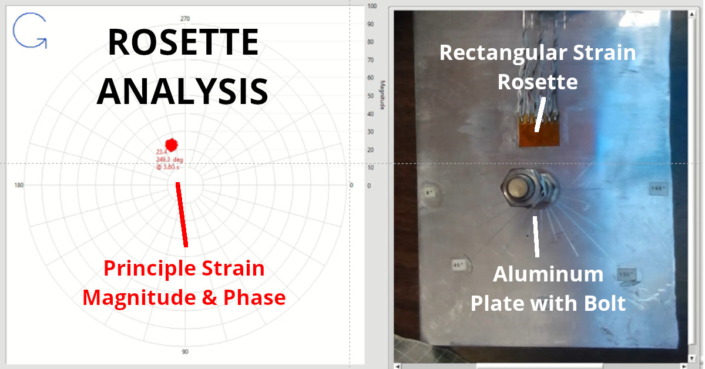

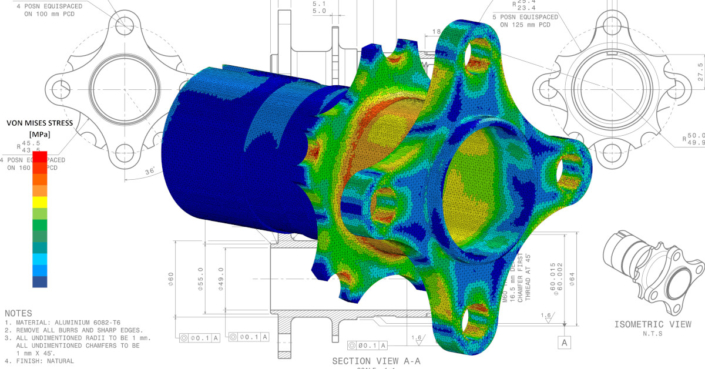

ITM is a structural test & measurement engineering service and software company that focuses on three vertical spaces: Industrial Monitoring, Testing Services, and iTestSystem structural testing software. Founded by Tim Carlier in 2001, ITM’s goal was to provide engineering measurement solutions that help companies reduce costs and improve efficiencies in their product development, manufacturing, and production activities. Today, ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauge (gage) installations, and data analysis solutions to clients on five continents. We are recognized National Instruments System Integrator.