Our team of engineers have decades of experience in performing structural testing in the aerospace, off highway, automotive, construction equipment, pulp & paper, and utility markets. Testing services include: Onsite Field Instrumentation & Testing Services, Custom DAQ Hardware Packaging, Impact Testing & Modal Analysis, Structural Dynamics Operating Tests, Data Logging, Unattended Data Acquisition, Road Load Data Acquisition (RLDA), Strain Gauging and Load Cell Design.

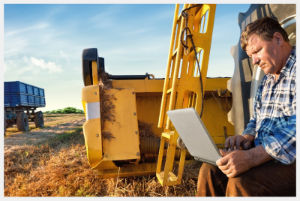

Our engineers can assist you with any part of the testing process or provide a complete turnkey solution. This includes test planning, onsite sensor installation and data acquisition and remote test monitoring.

· In-Vehicle Data Logging

· Structural Dynamics

· Strain Gauging

· Custom DAQ Hardware Packaging

· Load Cell Design

· Field Service

Design Validation

In order to validate new designs, our engineers and technicians will perform onsite sensor installation and operating data acquisition. Deliverables from these tests can include data files for analysis, detailed reports and design recommendations.

In-Vehicle Data Logging

Our customers often ask us to deploy an autonomous in-vehicle data logger to synchronously monitor and record vehicle CAN information along with various analog sensors and GPS signals on a fleet vehicle to test component prototypes.

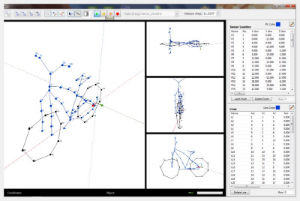

Structural Dynamics

To test a products structural dynamics, our engineers and technicians collect operating and modal data using iTestSystem Software and compare the results to FEA models.

Strain Gauging

Our engineers and technicians have epoxied, soldered and spot-welded strain gauges for applications ranging from high temperature exhaust systems to miniature load cell measurements. Every application requires a unique understanding of the strain measurement requirements and the application environs. Let us help you acquire quality strain data. https://strain-gauge-installation-measurement-service/

Custom DAQ Hardware Packaging

Save time and money by leveraging ITM’s experience for your data acquisition system needs. Our engineers can assist you with choosing the best hardware and packaging for your testing conditions. Our iTestSystem software can compliment your hardware to provide a complete testing solution.

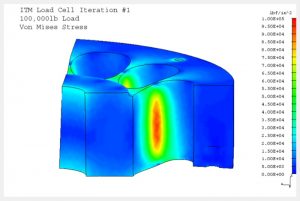

Load Cell Design

Measuring loads in a structure or product to verify models requires an familiar knowledge of materials, strain measurements and their limitations as well as calibration techniques. In many cases, we turn the structure or product into a load cell. Our engineers have provided customers with quality load cells and designs for decades.

Field Service

Our engineers and technicians can assist you with any part of the testing process. This includes test planning, onsite sensor installation and data acquisition and remote test monitoring. We have helped customers with projects on six of the seven continents.