MultiDAQ XL

Acquire Synchronous Data from Multiple Channel Types

Welcome to ITM’s iTestSystem MultiDAQ XL – the ultimate monitoring and data acquisition solution for your industrial and mechanical systems.

“MultiDAQ XL” is a powerful and flexible software application that allows you to monitor and record data from multiple channels of sensors and other measurement devices.

Examples include strain gauges, accelerometers and temperature sensors. Whether you need to perform real-time monitoring or long-term data logging, MultiDAQ XL has you covered.

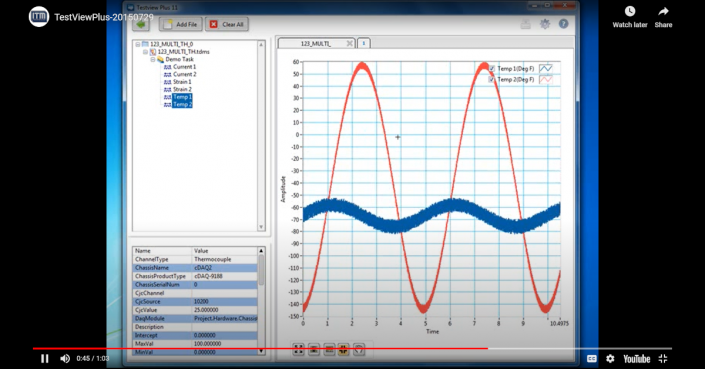

One of the key features of MultiDAQ XL is its ability to synchronize and acquire data from multiple channels simultaneously. This allows you to monitor and analyze multiple systems or parameters at the same time, giving you a comprehensive view of your equipment’s performance.

MultiDAQ XL also supports a wide range of measurement devices, including National Instruments (NI) data acquisition hardware. It can be configured to work with custom measurement devices. The software also allows you to export data in a variety of formats, such as Excel or MATLAB, for further analysis.

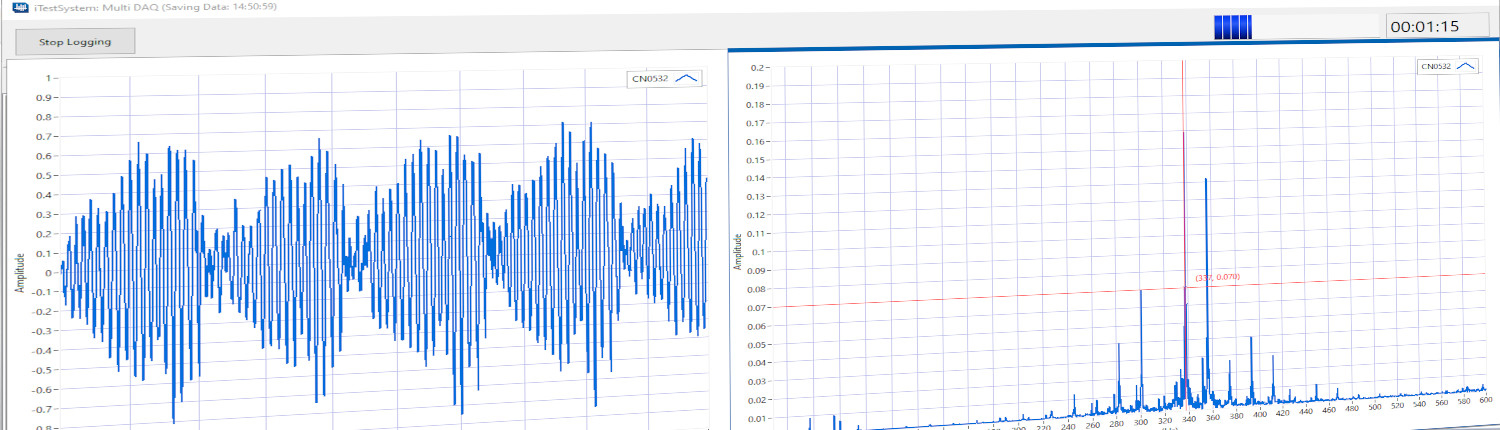

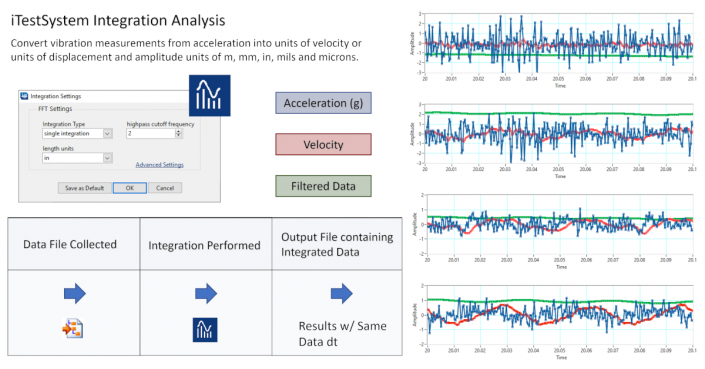

Advanced signal processing and analysis capabilities are also included in the MultiDAQ XL package. This feature allows you to perform frequency analysis, calculate overall vibration levels and identify specific frequency components in the data. This feature can be useful for troubleshooting and identifying issues in industrial equipment, as well as for monitoring and analyzing the performance of mechanical systems.

Additionally, MultiDAQ XL allows you to create custom graphical interfaces for displaying data in real-time. This feature can be useful for monitoring and troubleshooting equipment in the field.

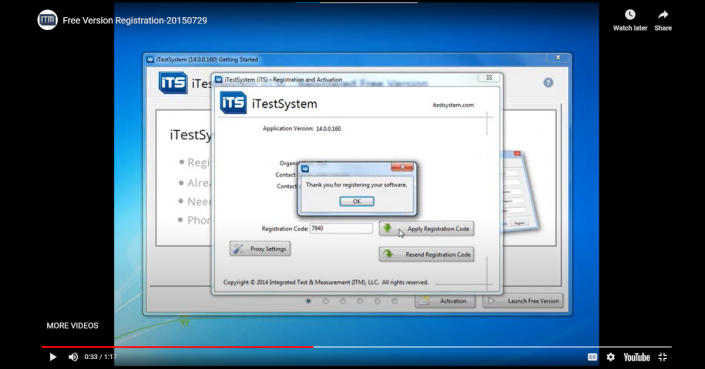

The iTestSystem MultiDAQ XL is easy to use and offers a user-friendly interface. It is designed to help you quickly set up and configure your data acquisition sessions. It also provides you with the tools you need to analyze and understand your data.

Whether you’re looking to improve the performance of your equipment, ensure compliance with regulations, or troubleshoot issues in your industrial or mechanical systems, MultiDAQ XL has the tools you need to get the job done.

Test Case for MultiDAQ XL

As engineers, it is crucial to monitor and measure the performance of our test articles to ensure they meet the desired specifications. One way to do this is by using a National Instruments (NI) CompactDAQ system in conjunction with ITM’s iTestSystem MultiDAQ XL data acquisition (DAQ) application. The combination of these two tools allows engineers to quickly and easily monitor an array of string pots on a test article, providing valuable insights into the performance of the test article.

String pots, also known as string encoders, are linear position sensors that are used to measure the displacement of a test article. They work by converting linear displacement into an electrical signal that can be easily read and analyzed by a DAQ system. By using an array of string pots, engineers can monitor multiple points on a test article simultaneously, providing a more comprehensive view of the test article’s performance.

The NI CompactDAQ system is a versatile and modular DAQ system that allows engineers to easily add and remove measurement modules as needed. This flexibility allows engineers to configure the system to suit the specific requirements of their test article. The CompactDAQ system can also be easily integrated with ITM’s iTestSystem MultiDAQ XL DAQ application, which provides a user-friendly interface for monitoring and analyzing data from the string pots.

Using the iTestSystem MultiDAQ XL app, engineers can easily configure the CompactDAQ system to read the data from the string pots and display it in real-time. The app also provides advanced analysis tools, such as filtering and FFT, which allow engineers to analyze the data in more detail. Engineers can also use the app to generate reports, which can be easily shared with other team members.

In conclusion, by using a National Instruments CompactDAQ system in conjunction with ITM’s iTestSystem MultiDAQ XL data acquisition application, engineers can quickly and easily monitor an array of string pots on a test article. This provides valuable insights into the performance of the test article, allowing engineers to make informed decisions about the design and development of the test article. The flexibility and ease of use of both the NI CompactDAQ and ITM’s iTestSystem MultiDAQ XL app makes it a great tool for any engineer looking to monitor linear position of the test article.

What is iTestSystem?

iTestSystem is a powerful and user-friendly data acquisition and analysis software that allows you to easily collect, process and analyze data from your test and measurement equipment. This engineering measurement software platform enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems.

Whether you’re performing vibration testing, strain gauge testing (strain gage testing) or any other type of testing, iTestSystem has the capabilities you need to get the job done.

Our team of experts specializes in data loggers, sampling rates, performance monitoring, daq devices, equipment failure, monitoring system, data acquisition systems, condition monitoring and much more.

About ITM

ITM is a structural test & measurement engineering service and software company that focuses on three vertical spaces: Industrial Monitoring, Testing Services, and configuration based test software, iTestSystem. ITM was founded by Tim Carlier in 2001 to help companies reduce costs and improve efficiencies in their product development, manufacturing, and production activities.

Contact our team today to learn more about iTestSystem, MultiDAQ XL, data acquisition (DAQ) and more.