Configuration

Customizeable Test Configuration Is Key to Effortless Testing with iTestSystem

Testing is an essential aspect of software development. It helps ensure the quality of the software and prevents bugs from slipping into production. However, testing can also be time consuming, repetitive and tedious.

The core feature of iTestSystem is Configuration, and it offers several benefits that make testing easier and more efficient.

What to expect using DAQ Configuration:

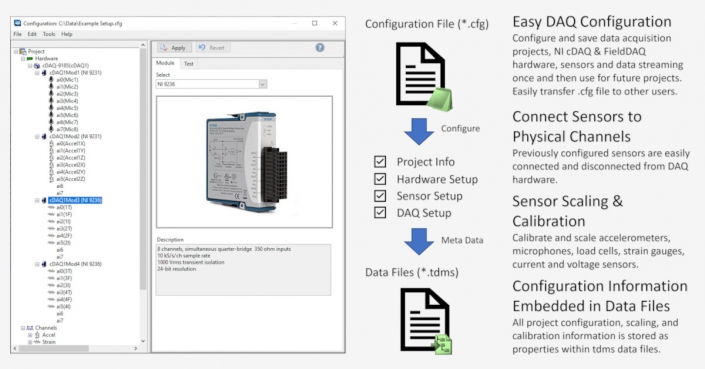

- Streamlined testing process: Configuration allows you to set up testing parameters in a central location, so you don’t have to manually configure each test. This reduces the time and effort required to set up tests and makes the testing process more efficient.

- Consistency: Configuration ensures that tests are run consistently and with the same parameters every time. This eliminates the risk of human error and ensures that tests are reliable and accurate.

- Time Savings: Configuration allows you to save and reuse testing configurations, so you don’t have to recreate them from scratch each time you run tests. This saves time and effort and makes testing more efficient.

- Easy collaboration: Configuration makes it easy for multiple team members to access and use testing configurations, ensuring that everyone is using the same testing parameters. This helps to eliminate confusion and ensures that tests are consistent and reliable.

- Enhanced flexibility: Configuration allows you to easily modify testing parameters as needed, making it easy to adapt to changes in your software or testing requirements.

In conclusion, Configuration is the key to effortless testing with iTestSystem. Its benefits streamline the testing process, ensure consistency, promote reuse, facilitate collaboration and enhance flexibility. If you want to make your testing process more efficient and reliable, iTestSystem with Configuration is the solution you need.

Test Case for Using Configuration

A manufacturer of hydraulic pumps wants to perform a vibration test on a new pump design. They create a new Configuration in iTestSystem that includes the following components:

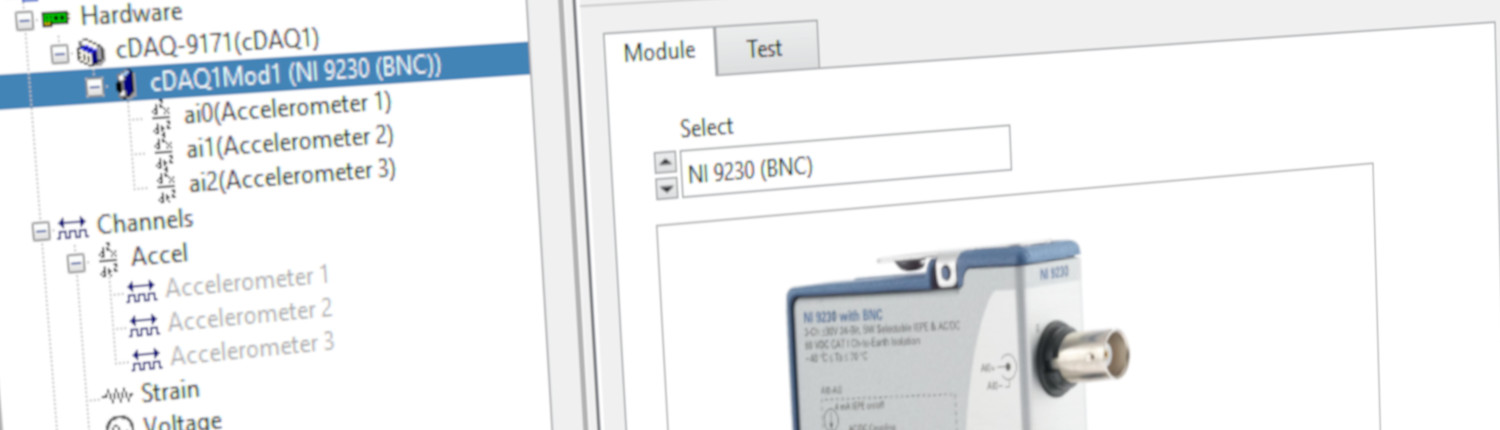

Hardware Setup: The manufacturer configures the hardware setup for data acquisition, including selecting the appropriate sensors to measure vibration, and connecting them to the data acquisition hardware.

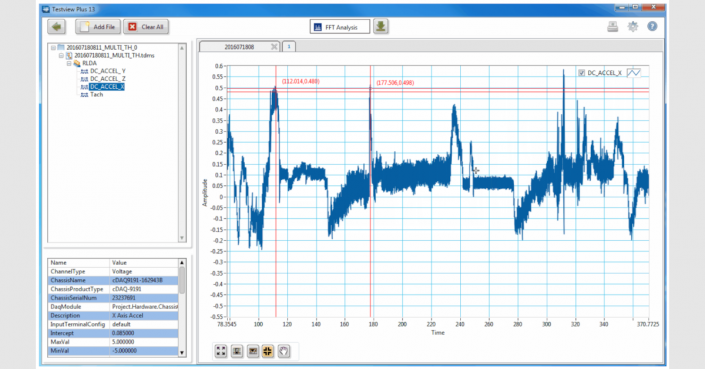

Data Acquisition Settings: The manufacturer configures the data acquisition settings, including selecting the sampling rate, data channels, and filters.

Test Profile: The manufacturer creates a test profile that outlines the steps of the vibration test, including the duration, frequency range, and vibration amplitude.

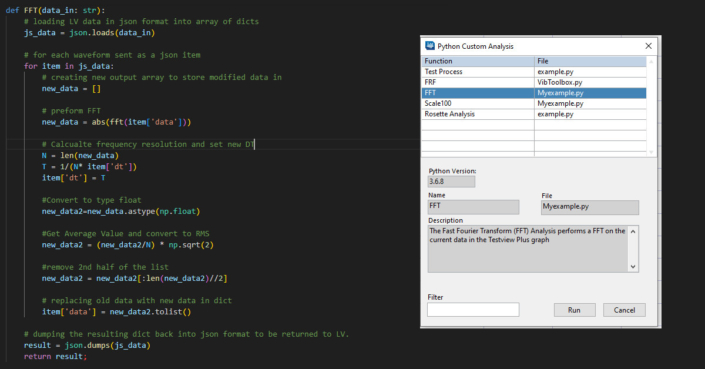

Analysis Settings: The manufacturer configures the analysis settings, including selecting the appropriate analysis algorithms, and setting up data filters.

Data Storage: The manufacturer configures the data storage settings, including selecting the data format, and setting up file naming conventions.

Once the manufacturer has created the Configuration, they can save it and use it to perform the vibration test on multiple pumps. This ensures consistency across all tests and allows for easy comparison of the results.

iTestSystem’s Configuration feature enables users to create custom test configurations that can be used to perform consistent and repeatable tests on industrial equipment. This can save time and resources while improving the accuracy and reliability of test results.

What is iTestSystem?

iTestSystem is a powerful and user-friendly data acquisition and analysis software that allows you to easily collect, process and analyze data from your test and measurement equipment. This engineering measurement software platform enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems.

Whether you’re performing vibration testing, strain gauge testing (strain gage testing) or any other type of testing, iTestSystem has the capabilities you need to get the job done.

Our team of experts specializes in data loggers, sampling rates, performance monitoring, daq devices, equipment failure, monitoring system, data acquisition systems, condition monitoring and much more.

About ITM

ITM is a structural test & measurement engineering service and software company that focuses on three vertical spaces: Industrial Monitoring, Testing Services, and configuration based test software, iTestSystem. ITM was founded by Tim Carlier in 2001 to help companies reduce costs and improve efficiencies in their product development, manufacturing, and production activities.

Contact our team today to learn more about iTestSystem, Configuration, data acquisition (DAQ) and more.