Custom Strain Transducer Design

Strain-based Transducers for Precision Measurement Applications

At Integrated Test and Measurement (ITM), we understand that no two projects are the same. That’s why we offer custom transducer design services to meet the unique needs of our clients.

With over 20 years of experience in the engineering industry, our team has designed and developed custom transducers for a wide range of applications. Our team of experts uses cutting-edge technologies and innovative design techniques to create transducers that are optimized for specific applications. We work closely with clients to understand their requirements and develop solutions that meet their needs.

Our custom transducer design services cover load cells, torque sensors, pressure sensors, and more. We have the expertise to design transducers that can withstand extreme environments, high loads and challenging operating conditions.

Client Stories

Below, we showcase our past experience in designing custom transducers for four different clients:

Tractor Manufacturer – Measuring Load on Power Take Off

One of our clients was a tractor manufacturer that needed to measure the load on a power take off (PTO). Our team designed a custom strain gauge load cell transducer that could accurately measure the load on the PTO. We worked with the client to determine the required specifications for the transducer, including the size, sensitivity, and accuracy. We then developed a prototype and conducted rigorous testing to ensure that it met the client’s requirements.

KitchenAid – Measuring Load on Food Processor Shaft

KitchenAid approached us to design a custom transducer to measure the load on the shaft of their food processor. The client was experiencing quality control issues and needed a more accurate way to measure load. Our team developed a custom load cell transducer that could measure the load on the shaft with high accuracy. We also integrated the transducer into the food processor to ensure it was easy to use and did not impact functionality.

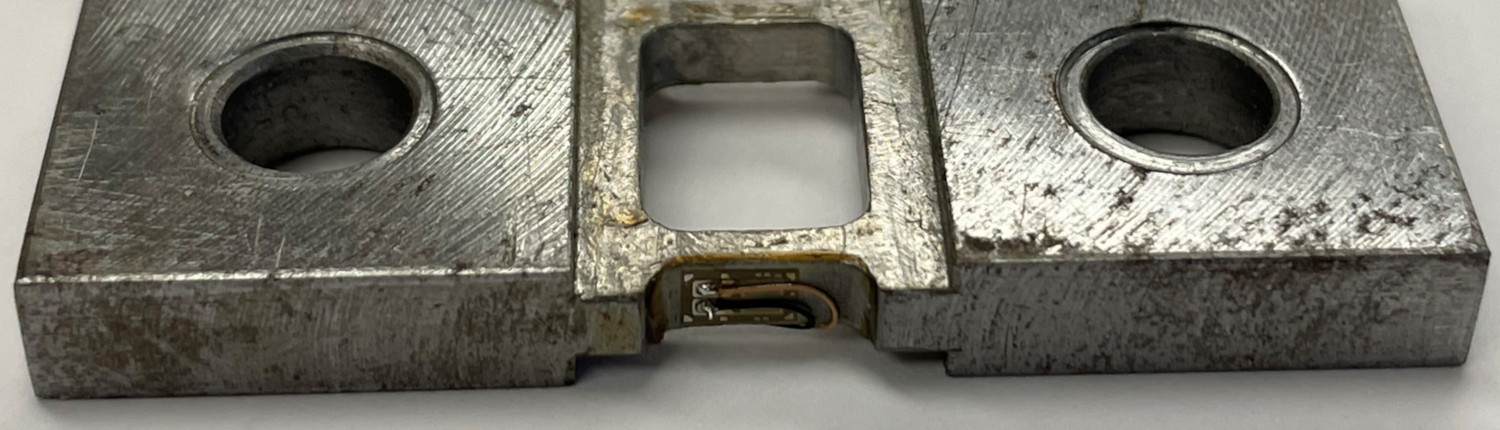

Worldwide Machining Company – Measuring Operating Loads on Machining Center Table

Another client, a worldwide machining company, needed to measure the operating loads on a machining center table to optimize performance. Our team designed a custom strain gauge load cell transducer that could measure the load on the table during operation.

We also developed a data acquisition system that could collect and analyze the data from the transducer. The client was able to use the data to make informed decisions about the operation and maintenance of their machines. The result was improved efficiency and productivity.

Geothermal Power Plant – Measuring Load on Composite Cooling Tower Fan Blade

We worked with a geothermal power plant located in the Philippines to design a custom transducer to measure the load on a composite cooling tower fan blade. The client needed to ensure that the fan blade was operating within safe limits to prevent damage and downtime.

Our team designed a custom strain gauge load cell transducer that could measure the load on the fan blade during operation. We also developed a wireless data acquisition system that could transmit real-time data to the client’s control room, allowing them to monitor the load on the fan blade from a safe distance.

Importance of custom transducers

Custom transducers are an essential tool for many industries, providing a range of benefits including increased efficiency, cost savings and improved product design. By designing and developing transducers specifically tailored to a particular application, clients can measure and analyze key data points with accuracy and precision, leading to better decision-making and streamlined operations.

Custom transducers can help businesses save money by reducing downtime and maintenance costs. By monitoring equipment loads, vibration, and temperature, companies can predict potential failures and perform proactive maintenance, reducing the likelihood of costly repairs or equipment replacement. This not only saves money but also minimizes the risk of unplanned downtime, which can result in lost productivity and revenue.

Custom transducers also play a crucial role in refining product design, allowing engineers to collect detailed data during the product development process. This data can be used to optimize the design of products, leading to improved performance, reduced costs, and enhanced user experience. By using custom transducers, designers can refine their products, making them more efficient and competitive in the marketplace.

Our experts specialize in predictive maintenance, equipment failure, pressure transducers, cost effective, reactive maintenance and much more.

Why turn to ITM

At ITM, we are committed to delivering customized solutions to meet the unique needs of our clients. Our custom transducer design services are backed by decades of experience in the engineering industry, and we use the latest technology and testing methods to ensure that our transducers are accurate, reliable and durable.

Whether you need a transducer for a specialized application or want to improve the performance of an existing product, we can help. Contact us today to learn more about our custom transducer design services.