PRODUCT DETAILS

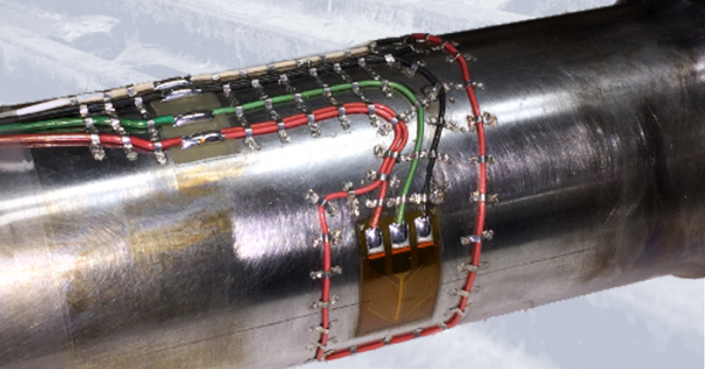

The Hopper Ash Level Thermocouple (HALT) System is a preventative maintenance tool that continually monitors the levels of ash within any given instrumented hopper. The HALT system consists of a Stainless Steel enclosure that houses an industrial controller and a series of industrial grade thermocouple sensors installed at equal increments along the wall of each hopper. As the hopper plugs and the ash levels increase, the thermocouples will become insulated by the ash and their respective temperatures will decrease thus providing an indicator for the ash level within the hopper.

SYSTEM BENEFITS

Those responsible for the operation or maintenance of thermal plant boilers know there is nothing trivial about hopper ash buildup. At a minimum, plugging can lead to decreased output, unscheduled maintenance, and lost revenue. Safety is a concern—ash cleaning can result in serious, sometimes fatal injuries.

Plant management wants to increase productivity, maximize equipment investment, become more sustainable, improve the bottom line, and ensure safe working conditions. Failing to reach some of those goals may not be a life-or-death situation, but worker safety can be just that. Ash can contain excess unburned carbon and the sudden injection of air or change in pressure can ignite the ash. Similarly, built-up ash can quickly collapse, bringing tons of ash down on maintenance personnel without warning. Each year boiler operators and plant maintenance personnel are needlessly injured, severely burned, and even killed by the effects of accumulation of hot ash. These incidents are completely avoidable.

Today a system is available to monitor ash buildup that allows plant personnel to anticipate plugging, while providing the information to safely clean and troubleshoot hoppers. This technology is helping thermal boiler plants take a big step toward keeping operators and maintenance personnel out of harm’s way, while at the same time keeping equipment running clean and efficiently.

Features

- Hopper Ash Level Thermocouple Measurements up to 1260C

- Hazardous Condition Warning Outputs with Local Status Indicator Lights

- Remote IO Server for ControlLogix

- Stainless Steel NEMA4X Controller Enclosure

- Standard 16-Chan Type-K Thermocouple Capacity

- Typical Seven (7) Thermocouple Sensors per Hopper