Optimizing Generator Health in Data Centers: The Critical Role of Vibration Monitoring in Data Centers and Factories

The data center and factory backup power markets are experiencing significant growth, driven by the increasing reliance on digital infrastructure and the need for reliable power solutions. The global data center power market is projected to reach approximately USD 33.44 billion by 2029, with a growth rate of 6.5% from 2024 to 2029 (GlobeNewswire). The U.S. backup power systems market is also expected to grow, reaching an estimated USD 4.47 billion by 2029 (Mordor Intell). These markets are expanding due to the rising adoption of cloud computing, mega data centers, and the integration of smart technologies (GlobeNewswire).

The importance of maintaining healthy primary and backup power systems cannot be overstated, especially in data centers and factories where power disruptions can lead to significant financial losses and operational downtime. Effective monitoring and maintenance of these systems ensure that they operate efficiently and are less likely to fail when needed most.

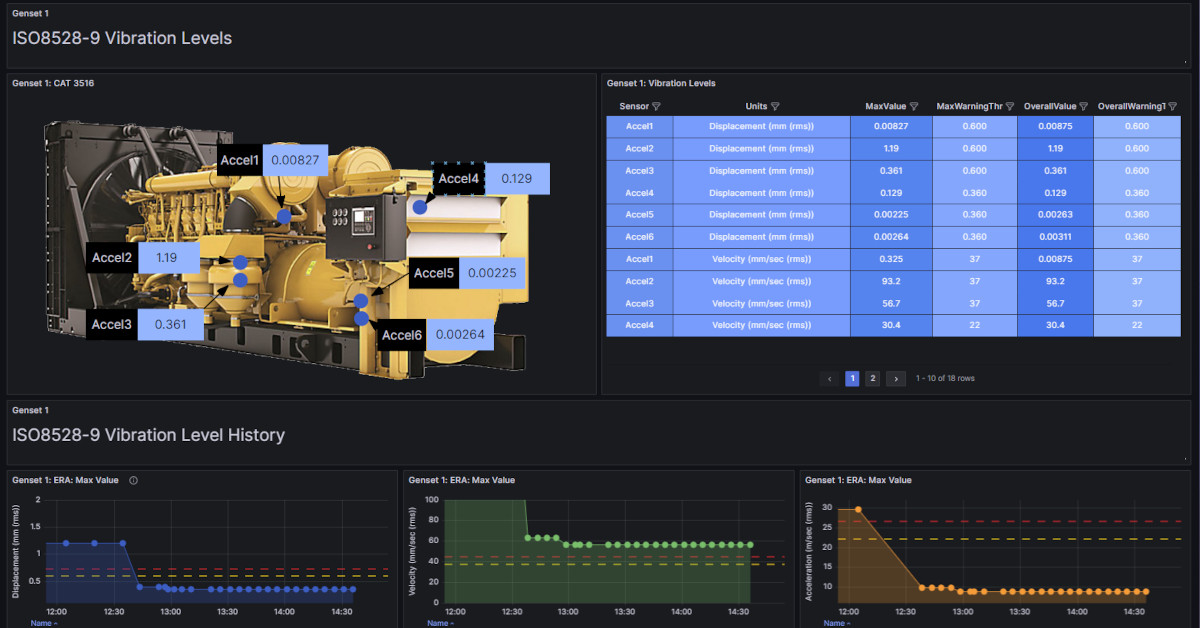

Our solution for monitoring vibration levels in generator sets is crucial for maintaining the health of these systems. This Genset Vibration Monitoring System not only measures overall vibration levels but also captures specific frequency bands, allowing for the early detection of potential issues like bearing failures or gear mesh wear. This system, detailed on iTestSystem.com, represents a sophisticated approach to preventive maintenance, minimizing the risk of unplanned outages and extending the equipment’s lifespan.

Grafana Genset Vibration Level Dashboard

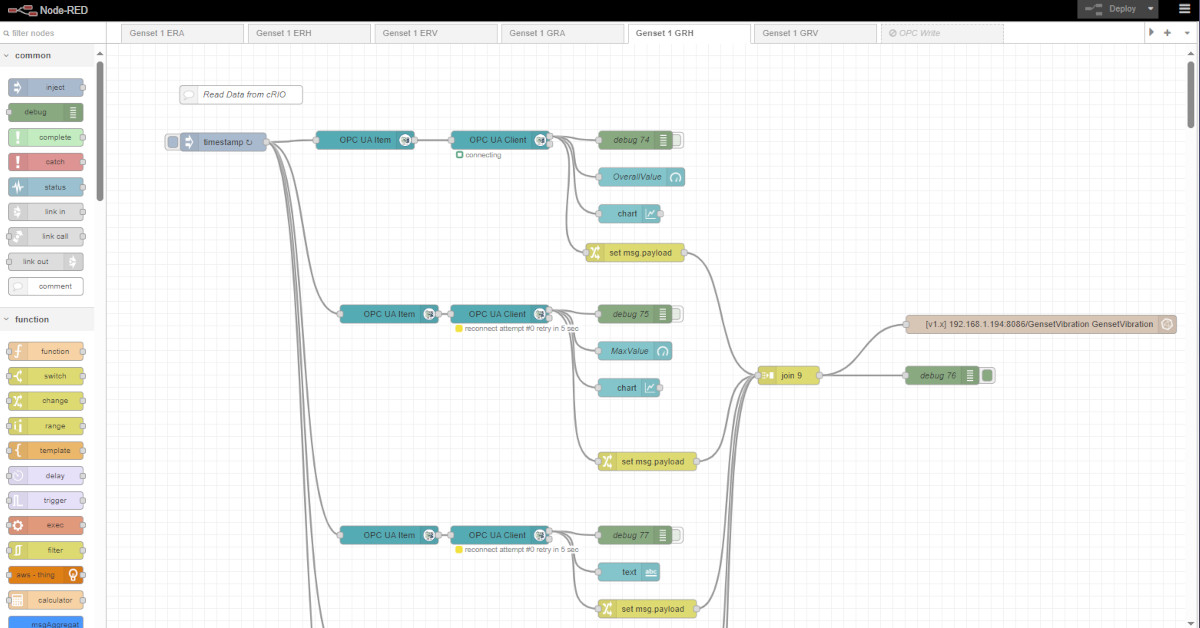

This system is compatible with several communication paths, including Modbus, Ethernet/IP, OPC UA, Webservices, and TCP streams, making it versatile for integration with various devices and data storage solutions. It can connect to local data control systems (DCS), cloud-based services like AWS and Azure, and factory PLCs. We have even demonstrated the flexibility of their system by using a Raspberry Pi as a local server in a cost-effective kiosk solution, employing tools like Node-Red and Grafana for data handling and visualization. This setup emphasizes the system’s adaptability and the growing trend of integrating traditional industrial data flows with modern data management and cloud solutions.

Node-Red OPC UA to InfluxDB JSON String

We also offer comprehensive monitoring services and equipment rental, including demo equipment for pilot trials, expanding the accessibility of their technology for businesses looking to experiment before committing to a full-scale rollout. These services are crucial for businesses aiming to optimize their power management strategies and ensure uninterrupted operations.

For more detailed information about ITM’s Genset Vibration Monitoring System and their monitoring services, you can visit our website at ITestSystem. If you would like to get in touch with one of our vibration experts, contact Josh Fishback via email josh.fishback@itestsystem.com or phone (844) 837-8797 x705.

London, UK - May 19, 2023: The RL-10 liquid-fuel cryogenic rocket engine used on the Centaur, S-IV and DCSS upper stages, exposed at Science Museum of London, England, United Kingdom-Alfredo - stock.adobe.com

London, UK - May 19, 2023: The RL-10 liquid-fuel cryogenic rocket engine used on the Centaur, S-IV and DCSS upper stages, exposed at Science Museum of London, England, United Kingdom-Alfredo - stock.adobe.com