PRODUCT DETAILS

Whether you are collecting data for operating deflection shapes (ODS) or measuring overall vibration levels for ISO standards, ITM’s Vibration Test Package contains all the hardware needed to acquire quality data.

The standard Vibration Test Package consists of a cDAQ 9189 chassis, 5 NI-9234 accelerometer input cards, power supply and 19 industrial accelerometers. These items are packaged in a rugged pelican case. Use our iTestSystem software to stream data from the cDAQ chassis to your laptop. iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ hardware.

CUSTOMIZED OPTIONS AND CONSIDERATIONS

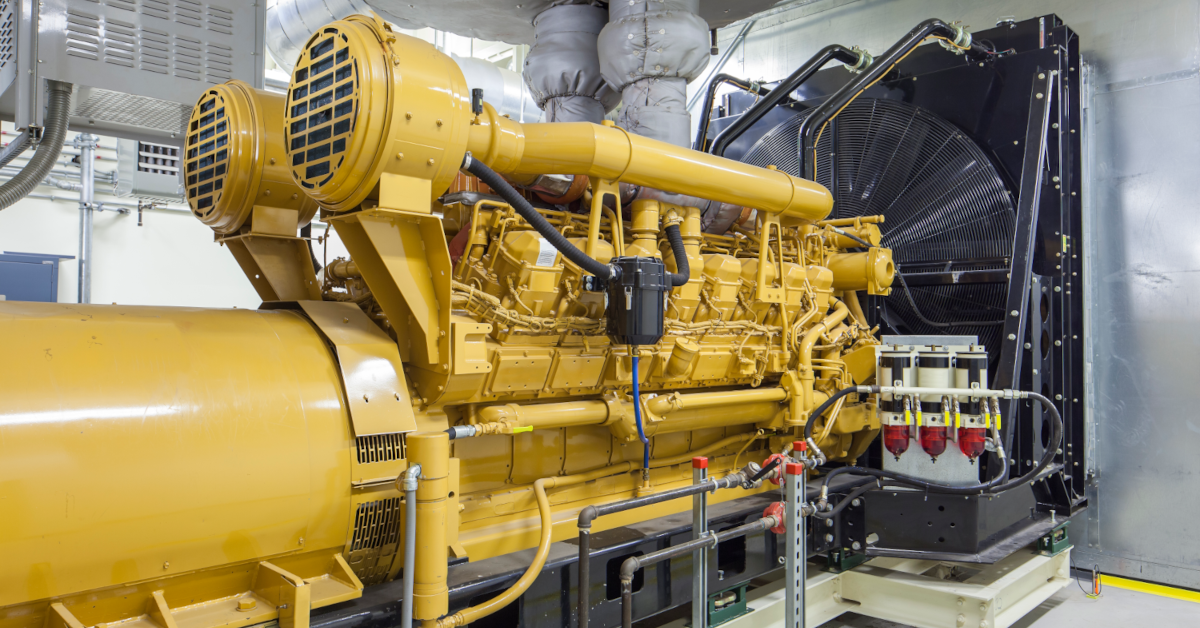

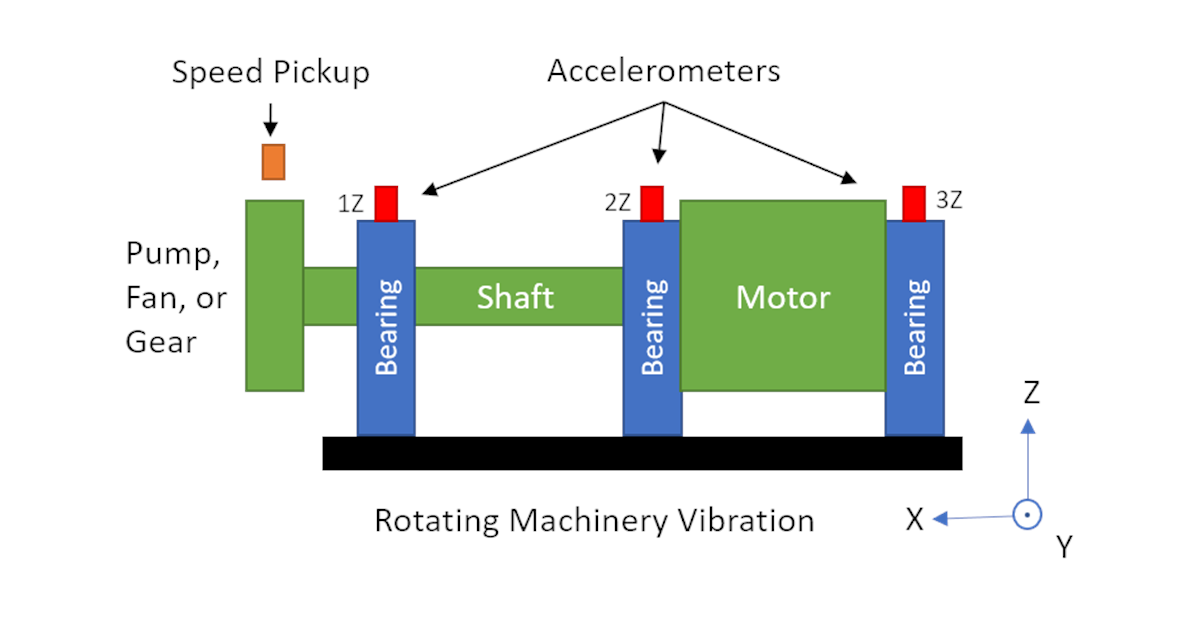

ITM can also help you design a custom vibration test as many variables can determine the accuracy of the data you collect. For example, be sure to consider measurement location when designing your test. When measuring vibration on rotating equipment such as motors, pumps, and generators, for example, the most common measurement location(s) are on the shaft bearing housing(s) at the shaft centerline. At this location, typical vibration levels perpendicular to the shaft are < 100 g and the frequency range of interest is < 5000 Hz. A general purpose single axis piezoelectric accelerometer with either a 10 mV/g or 100 mV/g sensitivity fits this criteria. Other characteristics to consider include size, mounting options, cable connections, grounding, and cost. Several mounting options are available. They include magnetic bases, adhesive bases and stud mounts. The mounting option you choose affects the frequency range of your accelerometer measurements.[Text Wrapping Break]

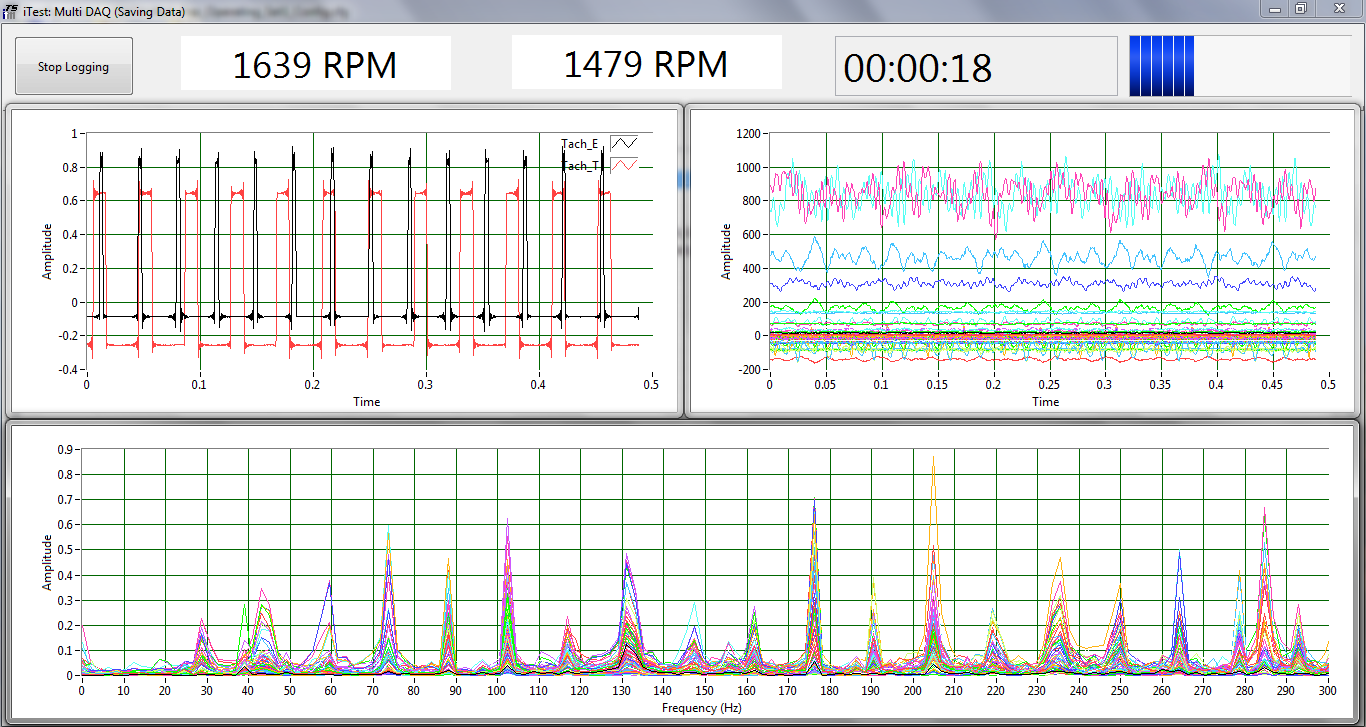

The most important part of the data collection process is choosing a sample rate. If you choose a sample rate that is too low, the data you have collected is useless. According to the Nyquist Theorem, data must be sampled at a rate that is at least 2X the highest frequency you wish to record. Most test engineers like to sample from 2.5x to 10x higher than the highest frequency they wish to collect. Typical general vibration measurements are sampled at 2kHz. However, vibration data collected from accelerometers and gear teeth pulses which is used for phase and speed measurements, and bearing fault detection, and torsional vibration determination must be collected at much higher sample rates like 50kHz.