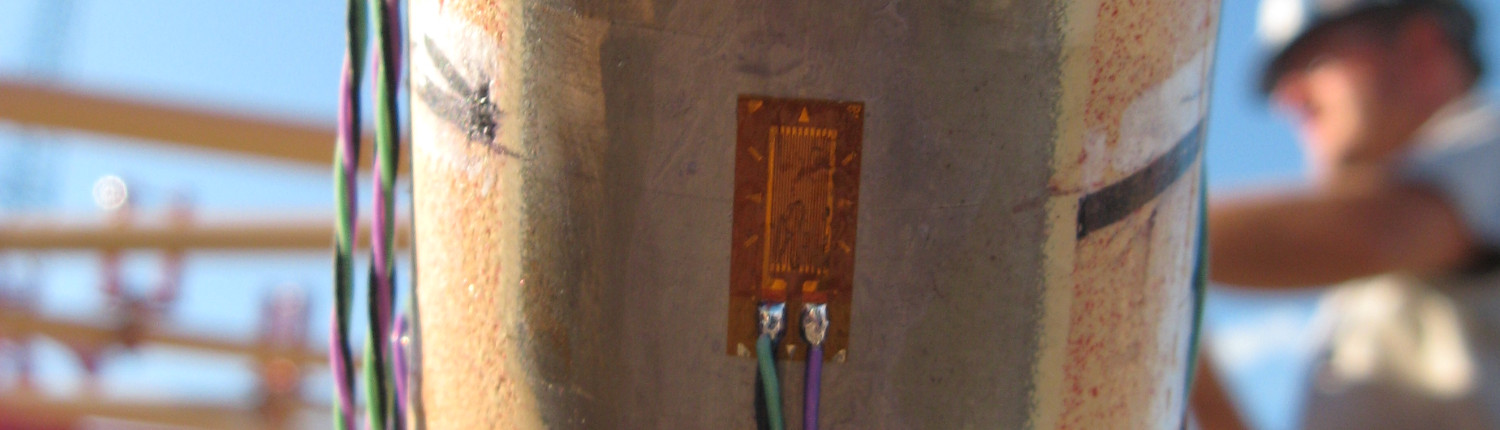

Onsite Strain Gauge Installations

Our team of engineers and technicians install strain gauges around the world.

At Integrated Test and Measurement (ITM), we offer onsite strain gauge installation services to meet the needs of clients in a variety of industries.

Our team of experienced engineers provide a convenient solution for clients who require strain gauges to be installed in their equipment or structures. Our engineers and technicians have epoxied, soldered and spot welded strain gauges for applications ranging from high temperature exhaust systems to miniature load cell measurements.

Every application requires a unique understanding of the strain measurement requirements including installation environment. If the installation is to survive in the field you must plan for the conditions it will undergo. Three important variables that you should account for are temperature range, liquid exposure, and potential impact forces. These variables determine the type of strain gauge, epoxy, solder, wiring, coating, and impact/wear protection to use in the application.

Aerospace Expertise

One area where we have extensive experience in is the aerospace industry. We understand the unique challenges associated with designing and installing strain gauges in aerospace applications, where precision and reliability are critical to safety and success. Our team of engineers has worked on numerous aerospace projects, including the Artemis rocket project.

ITM engineers were tasked with installing strain gauges on the Space Launch System (SLS) rocket, which was part of the Artemis rocket project. The sensors were installed to measure the loads on the rocket during launch and flight, providing critical data for the engineers to optimize the rocket’s performance and ensure its safety.

The installation was a complex process, requiring precise positioning and alignment to ensure accurate readings. We worked closely with the client to understand the requirements for the strain gauges and developed a custom installation plan that met their needs.

Our team of engineers has also worked on numerous other aerospace projects, including installing strain gauges on aircraft, helicopters, and satellites. We understand the unique challenges associated with designing and installing strain gauges in aerospace applications and have the expertise to provide customized solutions for our clients.

More Service Industries

We offer onsite installation services for a variety of applications, including automotive, construction, manufacturing, and more. We use the latest technology and testing methods to ensure that our strain gauges are accurate, reliable, and durable, providing our clients with the data they need to optimize their operations and ensure their equipment’s safety.

Our onsite installation services provide a convenient solution for clients who require strain gauges to be installed in their equipment or structures. Our team of engineers will work with you to develop a customized solution that meets your specific needs.

We use the latest technology and testing methods to ensure that our sensors are accurate, reliable, and durable, providing our clients with the data they need to optimize their operations and ensure their equipment’s safety.

Installation on Civil Structures

ITM also has extensive experience providing strain gauge services for civil structures. We have worked on a wide range of projects, including bridges, dams, buildings, and pipelines. Our team has designed and installed custom sensors to monitor structural integrity, assess load-bearing capacity, and detect potential issues before they become critical.

We help our clients ensure the safety and reliability of their structures. With our state-of-the-art equipment and highly skilled technicians, we can provide accurate and reliable data to inform decision-making and improve the lifespan of civil structures.

Installation on Printed Circuit Boards

ITM has extensive experience in installing strain gauges on printed circuit boards (PCBs). Our skilled technicians are trained to handle delicate electronic components and apply these sensors in a precise and accurate manner.

We understand that PCBs are often used in critical applications where even the slightest deviation can lead to failure. Whether it’s a prototype board or a high-volume production run, ITM has the expertise to handle any strain gauge installation project on PCBs. We ensure that our installations on PCBs are reliable, durable and deliver the high-quality data required for accurate testing and analysis.

Our experts specialize in data acquisition, strain gauge testing, sensor installation, structural testing, vibration analysis, signal conditioning, pcb strain gauge, instrumentation, strain gauge calibration, strain gauge analysis, strain gauge monitoring, strain gauge consulting, stress analysis, materials testing, mechanical engineering, electrical engineering, industrial testing, engineering services and much more.

We also have expertise in application of strain, strain gage, analog signal, electrical resistance, quarter bridge, bridge configuration, input signal, weldable strain, electronic device, strain gauges work, wheatstone bridge, rail monitoring

At ITM, we are committed to delivering customized solutions to meet the unique needs of our clients. We use the latest technology and testing methods to ensure that our strain gauges are accurate, reliable and durable.

Whether you need strain gauges for a specialized application or want to improve the performance of an existing product, we can help. Contact us today to learn more about our onsite strain gauge installation services.