PRODUCT DETAILS

The Clinker Detection (CDS) System is an ITM proprietary technology for measuring both the size and frequency of deposits that impact a utility boiler floor or bed. This technology enables operations personnel to shorten boiler outages, identify fouling problems and optimize soot blower operations.

This tech has introduced a brand new approach to address “fouling” in coal-fired power plants as well as the pulp and paper industry.

SYSTEM BENEFITS

- Determines where boiler fouling has occurred

- Optimizes soot blower operation

- Identifies any damaging clinker impacts on the bed/floor

- Shortens the duration of chill & blow events

Why Should I Install a Clinker Detection System?

ITM’s Clinker Detection System has proven it can boost sootblowing efficiency, save steam and curb maintenance headaches in plants by putting a novel data-collection technology to work.

Fouling occurs inside black-liquor recovery boilers (as part of the pulping process) and in coal-fired utility boilers when incombustible byproducts adhere and insulate furnace components — the steam-generating tubes in the boiler’s superheater — thereby reducing steam production and even halting operations altogether to allow for maintenance cleanings.[Text Wrapping Break]

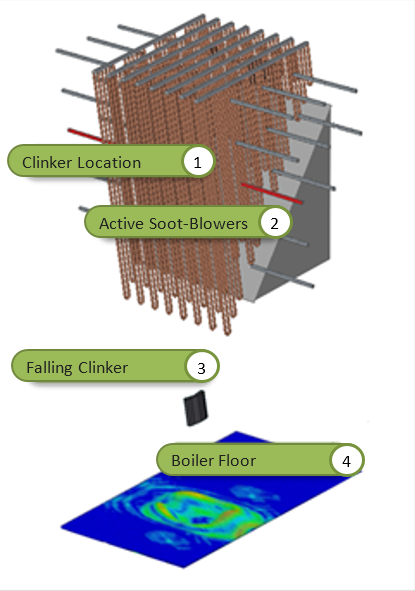

For decades, these industries have relied on sootblowers — long rotating lances that are inserted through the superheater tubes during combustion — to blow off soot and dislodge clinkers, the masses of ash deposits that form around superheater tubes. Clinkers, some of which reach the size of a small car, can damage components as the masses plummet up to 150 feet and crash to the boiler floor.[Text Wrapping Break]

As the name implies, ITM’s Clinker Detection System (CDS) uses the falling masses themselves to inform operations and ultimately boost efficiencies by collecting impact data as clinkers impact with the boiler floor. The key to the technology involves mapping and instrumenting the floor with industrial sensors, which measure the size and frequency of deposits that impact while also identifying which sootblower caused the clinker to fall.

ITM points out that optimizing sootblowing doesn’t only save money, it also has a significant environmental effect as plants don’t have to burn as much fossil fuel to generate electricity since they will consume steam more efficiently. The CDS can be used to gauge the effectiveness of other boiler cleaning tools, too, including sonic horns, pulse-detonation cleaning events as well as chill-and-blow cleaning events.

Recent News

ITM presented its Clinker Detection System (CDS) technology at the International Chemical Recovery Conference (ICRC – 2017) in Halifax, Nova Scotia on May 24th at 10:30AM.

During this presentation, ITM’s president Tim Carlier discussed how a recovery boiler CDS was used to detect superheater fouling and its impacts on boiler operation. His presentation and the white paper submitted to the ICRC committee are linked below.

CDS White Paper - ICRC 2017CDS Presentation - ICRC 2017

SYSTEM COMPONENTS

- Stainless steel NEMA4X enclosure

- Industrial real-time Compact RIO controller

- Industrial accelerometers

- Real Time data processing and analysis software

- DCS and/or PI System integration via industry standard interfaces

- Detailed Installation Instructions