FMS PRODUCT DETAILS

ITM’s Fouling Monitoring System (FMS) is a boiler optimization and preventative maintenance tool that continually monitors levels of ash/soot/slag buildup on platens/tubes of an instrumented recovery and power boilers.

In a typical boiler, fuel is burned inside the furnace, creating hot gas which heats water in the steam-generating tubes. In the case where the fuel is coal or black liquor, the flue gas often contains a significant amount of carry-over, which collects on the boiler tubes causing buildup. This buildup, also known as fouling, decreases the efficiency of the heat being transferred to generate steam while also increasing the risk of plugging the boiler and taking it offline altogether.

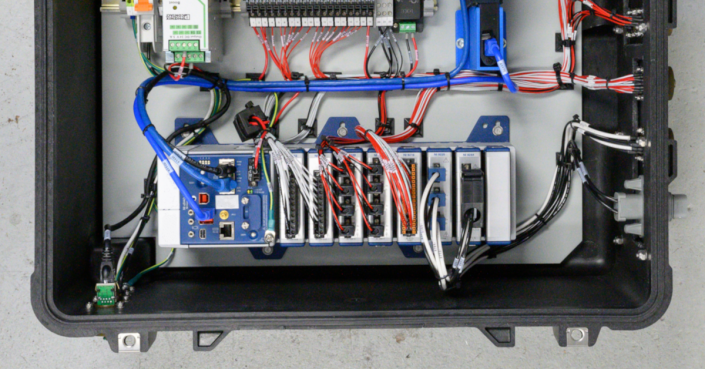

A typical FMS system consists of an industrial controller with IO modules housed in a stainless steel enclosure for collecting, processing, and publishing data from a series of ruggedized strain gauge/load sensors installed on boiler platen/tube support structures. This tool outputs soot/slag buildup levels relative to each instrumented support structure giving boiler operators actionable feedback for improving boiler efficiency, preventing boiler plugging, and planning future outages.

FMS PLANNING & INSTALLATION

ITM engineers will work with you to plan the FMS system installation by working with plant resources and contractors, provide detailed installation documentation, and then perform the final onsite system and sensor installation.

IMPROVING BOILER EFFICIENCY

FMS systems can be deployed in conjunction with our other boiler monitoring systems, Sootblower Fouling Detection (SFD) System & CDS Systems, to optimize boiler cleaning and preventative maintenance processes.

FMS systems can be deployed in conjunction with our other boiler monitoring systems — Sootblower Fouling Detection (SFD) System & Clinker Detection System (CDS) — to optimize boiler cleaning and preventative maintenance processes.

The Sootblower Foulding Detection System is an ITM proprietary technology for the measurement of fouling along the path of a sootblower in recovery and utility boilers, while ITM’s Clinker Detection System uses the falling masses (called clinkers) themselves to inform operations and ultimately boost efficiencies by collecting impact data as those clinkers impact with a boiler floor. The key to the technology involves mapping and instrumenting the floor with industrial sensors, which measure the size and frequency of deposits that impact while also identifying which sootblower caused the clinker to fall.

To learn more about using these tools, contact Ryan Welker. Email: ryan.welker@itestsystem.com

Features

- Measures Soot/Slag Buildup Levels and Locations on Boiler Tubes

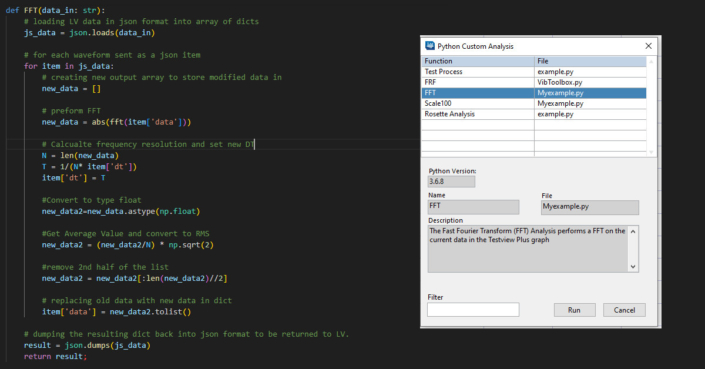

- Industrial Controller with Embedded FMS Load Processing Technology

- Calibrated 4-20mA Strain Based Load Sensors

- Standard 56 Channel 4-20mA Load Sensor Capacity

- Periodic Auto-Calibration to Ensure System Health

- Stainless Steel NEMA4X Controller Enclosure

- Integrates with ControlLogix Hardware via Ethernet/IP Communication

- Outputs Boiler Buildup to Historians and Data Collection Systems (DCS) via Modbus, OPC, or PI UFL

- Service Plans Available