Author: Mark Yeager – Integrated Test & Measurement (itm), LLC

Industry: On-Highway Vehicles

NI Products Used: NI cRIO-9074, NI-9174

GALLERY IMAGES:

Next Level Vehicle Component Testing

ITM delivers custom in-vehicle data logging solution that captures CAN bus information alongside analog sensor data.

The R&D office was filled with Borg Warner’s application engineers as they eagerly awaited a first-ever view of their product — a fan drive— as it performed under the hood of a commercial truck more than a thousand miles away. A display of gauges, needles and dials showed precisely how their product performed during every day over-the-road stress. The data feeds showed fan speed, temperatures around the fan drive, and CAN bus data including engine speed and torque along with coolant, air and oil temperatures. It was an impressive view they had never seen before.

The firm delivering those real-world snapshots of data is Integrated Test & Measurement (ITM) from Milford, Ohio. For years, Borg Warner, a global powertrain technologies company, has turned to ITM to gather data for engine-cooling components. Thanks to software innovations at ITM, the firm has taken in-vehicle data logging to the next level. Important vehicle information from the CAN (Control Area Network) bus alongside sensor data can be collected and shared real-time, which allows their client to remotely monitor tests as they happen.

“Not only are we correlating information that is broadcast by the vehicle with analog sensor information”, says ITM engineer Ryan Welker, “we can gather data and feed it back to our customer in a way that is configurable to their needs. We can also incorporate GPS technology, which is very valuable. Now they can see if a vehicle is traveling up and down steep hills and see what influence it has on duty cycles of their product.”

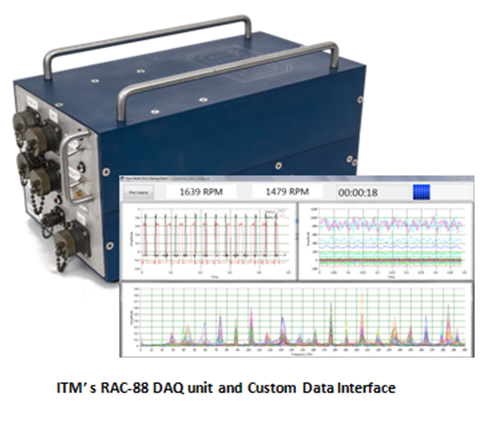

To perform the tests, ITM uses a RAC-88 data acquisition package that consists of a National Instruments cDAQ chassis and associated hardware as well as an embedded PC that runs ITM’s off-the-shelf iTestSystem software application. The package is equipped with a broadband router and cellular air cards for remote data connectivity and transmission.

Borg Warner engineers point out how crucial it is in today’s competitive environment to get the clearest picture of how products will behave under actual conditions. “In order for us to fine-tune our components and ensure they are going to be durable, we need to be able to test them with a very accurate understanding of exactly how they are being used in the field,” says Livingston. “For the first time, we have the data that gives us the confidence that the limits we are testing to are accurate to the actual usage in the real world.”

Livingston says one of the biggest assets of using ITM for the months-long testing is the constant and consistent monitoring and communication from Welker, who uses cloud sharing to communicate data sets to Borg Warner in five-minute increments, then merges files into a day-long view. Welker even tracks the testing on the weekends on his smart phone and can go online to reconfigure file sizes or sample rates.

“I couldn’t imagine it being any easier in terms of finding someone to help us conduct this work and provide the output we are looking for,” says Livingston. “Because of their experience, they know what to ask and what to do, and they take care of so many things that we only have to provide a minimum amount of input to get what we need done. I can now focus on using the data to design tests that result in a better product.”

From a pragmatic perspective, Welker points out that the constant monitoring also allows for a far more efficient testing process. Not only do their customers get data quickly (instead of waiting months until a test is complete to begin analysis), but also, any issues that disrupt data collection are brought to light immediately.

Beyond having the ability to build more efficient tests, Welker reiterates the importance of being able to gather more complete data by accessing the vehicle’s CAN bus network.

“This opens the doors to a lot more opportunities for customers that build engines and components,” he says. “Those vehicles are spitting out all kinds of valuable information over the CAN system that we can now correlate with analog test data. This allows us to provide customers with a far more accurate picture of exactly what is going on with their equipment.”

Contact Information: For more information on this Case Study, please visit iTestSystem.com or contact: RyanWelker – Integrated Test & Measurement (ITM), LLC – ryan.welker@iTestSystem.com