A Strain Gauge Rosette Analysis Demonstration

In the fields of engineering and materials science, measuring and analyzing strain rosette data is essential for assessing the structural integrity and performance of materials. To showcase the capabilities of strain gauge rosette measurements, we developed a test setup with a rectangular strain gauge rosette affixed to an aluminum plate. In our demonstration, we applied directional force to a bolt positioned close to the strain rosette. Utilizing the Rosette Analysis Tool from iTestSystem, in conjunction with NI’s cDAQ hardware and LabVIEW software, we were able to display the principal strain magnitude and phase concurrently as varying forces were exerted on the test setup.

Understanding Strain Gauge Rosettes

Strain gauge rosettes are essential for collecting strain data from multiple directions at a single material point. This is especially important when the stress direction is uncertain, enabling a thorough stress state analysis. By placing the rosette near a bolt on an aluminum plate, the experiment accurately measured strains from applied forces, determining the force’s magnitude and direction with precision.

Enhanced Analysis with ITM’s TestView Plus

A highlight of this experiment was the real-time strain data visualization, enabled by ITM’s TestView Plus within the iTestSystem suite. This tool allowed for instant data plotting on a polar plot, emphasizing the value of sophisticated analysis in engineering research and diagnostics. Viewing these measurements instantly offers direct insight into mechanical behavior under stress, aiding in design and safety decision-making.

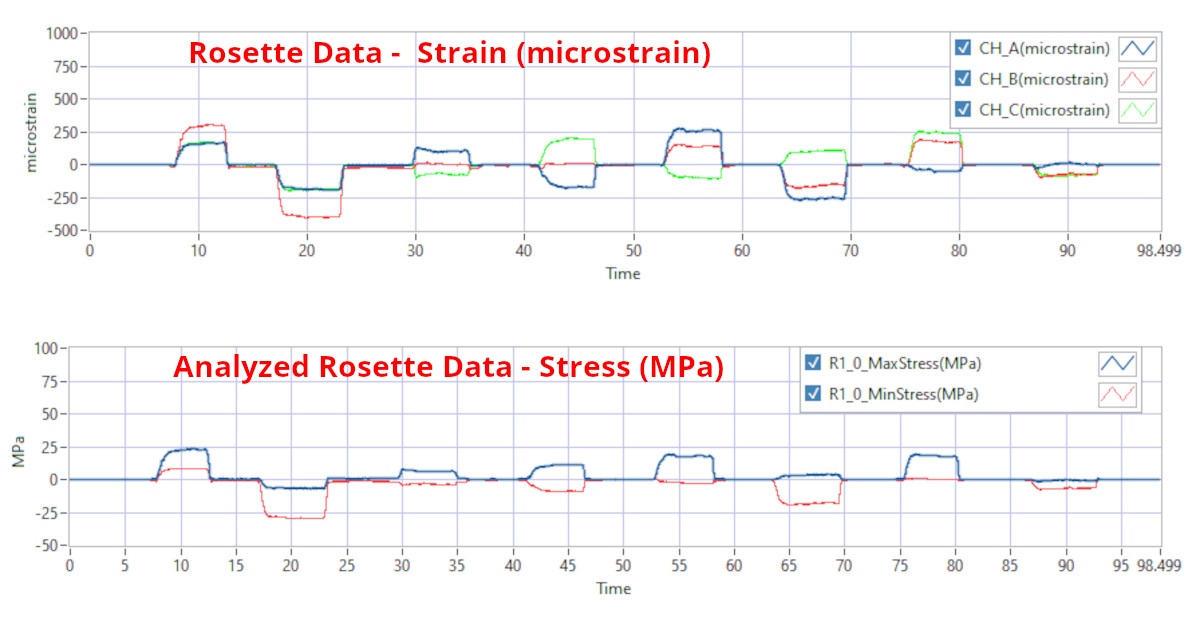

Raw Strain Rosette Data and Analyzed Stress Data Displayed in a TestView Plus Graph

NI Hardware for Accurate Data Collection

The setup included the NI-9236 350ohm strain module and the cDAQ-9181 single slot compact DAQ chassis, showcasing the efficiency and dependability of NI’s data acquisition hardware. Designed for interfacing with a variety of sensors, including strain gauges, the NI-9236 module and the durable cDAQ-9181 chassis highlight NI’s role in enhancing engineering experiments and data collection.

ITM’s Strain Gauging and Testing Services

ITM excels with its cutting-edge software solutions like TestView Plus and through its comprehensive strain gauging and testing services. From installing strain gauge rosettes to detailed data analysis and interpretation, ITM assists clients through the complexities of strain measurement and material analysis. This test is a proof of ITM’s ability to provide advanced measurement solutions meeting the stringent requirements of contemporary engineering projects.

Strain Gauge Rosette Data and Finite Element Analysis (FEA)

Strain gauge rosette data plays a crucial role in verifying Finite Element Analysis (FEA) models, bridging the gap between theoretical predictions and real-world behavior. FEA models are sophisticated computational tools used to predict how materials and structures will react under various conditions, including stress, strain, and deformation. However, for these models to be reliable, they need to be validated against empirical data. This is where strain gauge rosettes come into play.

Conclusion

The combination of precise strain measurement methods, sophisticated analysis software, and sturdy hardware marks a significant evolution in material testing and structural analysis. The partnership of ITM’s specialized services and NI’s technological expertise not only showcased the effectiveness of current engineering tools but also set the stage for future developments in the sector. For those interested in further exploration, detailed information on the hardware and software used is available at ni.com and itestsystem.com, respectively.

This venture into strain measurement and analysis highlights how expert services and technological advancements can profoundly improve our understanding and assessment of material properties, leading to designs and structures that are both safer and more efficient.

For more information about ITM’s Strain Gauging Services or our Engineering and Testing Services, contact Ryan Welker at (844) 837-8797 x702.