Strain Gauge Bridge Completion Modules

Quarter Strain Bridge with Completion Circuit

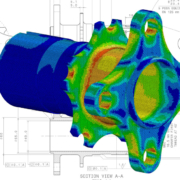

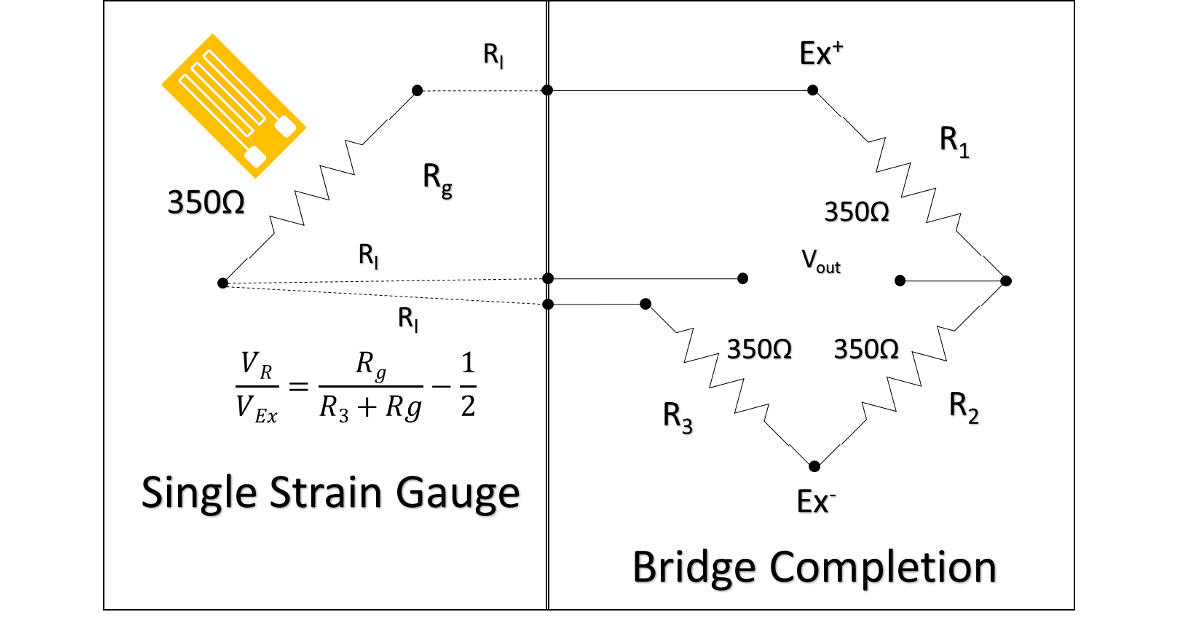

The most common strain gauges used to quantify the state of stress on a test specimen’s surface, are uniaxial and rosette gauges. For accurate measurements of stress and strain, these uniaxial and rosette gauges are independently connected as a Wheatstone bridge in a 3-wire quarter-bridge or half-bridge arrangement.

Strain Gauge Installations for Field Testing | Strain Gauge Services | tshirt-Strain Gauge Services Rectangular Rosette | Engineering Data Acquisition Tools: NI-9237 Bridge Input Module

Custom PTO Shaft Strain Gauge Transducer by ITM | Custom Strain Transducer Service | Custom Strain Gauge Measures KitchenAid Shaft Load

Today, most high-end data acquisition equipment manufacturers provide signal conditioning options for collecting data from single strain gauges. Signal conditioning for strain gauges usually includes circuitry for bridge excitation voltage, quarter and half bridge completion arrangements, and shunt calibration.

What we offer

Are you looking for expert assistance with accurately measuring stress and strain? or, Do you need to rent or buy data acquisition equipment to collect stress and strain data?

Sometimes you may need to view or collect data from a single strain gauge using a device that only has analog voltage inputs and no strain signal conditioning. This was precisely the case when I was working with the HX711 load cell/strain amplifier. The HX711 requires a full bridge input so I instrumented my test specimens as such. If I needed to use a single strain gauge with the HX711, I would have had to use an external bridge completion circuit.

What are your options for measuring single strain gauges with a device that only has voltage inputs or full bridge inputs?

Option 1: Buy a commercial off the shelf bridge completion modules.

The list below gives the specifications for some available bridge completion modules. I plan on adding more completion modules to this list for future reference, so send me any additional completion options.

Strain Gauge Completion Modules

|

|

|

|

| Manufacturer | NI | VPG | Campbell Scientific |

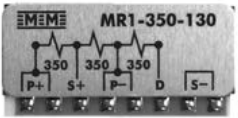

| Model # | NI 9926, NI 9945, NI 9944 | MR1-10C-129, MR1-350-130, MR1-120-133 | 4WFBS1K, 4WFBS350, 4WFBS120 |

| Description | 3-Wire Quarter Bridge Completion | 3-Wire Quarter Bridge Completion | 3-Wire Quarter Bridge Completion |

| Resistance | 1000 Ω, 350 Ω, 120 Ω | 1000 Ω, 350 Ω, 120 Ω | 1000 Ω, 350 Ω, 120 Ω |

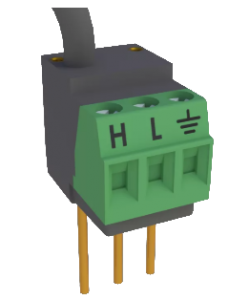

| Strain Gauge Connector | Terminal Block | Solder Tab | Terminal Block |

| Device Connector | RJ50 | Solder Tab | Pins and Lead Wire |

Option 2: Build your own circuit.

If you are building a product or are in the strain business long term, building your own circuit may be a cost effective alternative to the potentially more expensive off the shelf bridge completion option. I have built a few bridge completion circuits in the past. Here is a list of things to keep in mind when designing a circuit.

- Use high precision, low resistance temperature coefficient resistors

- The voltage source used for bridge excitation should be from a stable source like a reference since the output of a Wheatstone bridge is inversely proportional to the excitation voltage Vout/Vex.

- Use remote sensing to compensate for errors in excitation voltage from long lead wires

- Amplification will increase measurement resolution and improve signal-to-noise ratio

- Filter data to remove external, high-frequency noise

For more information about bridge completion or our strain gauging services, contact Ryan Welker @ (844) 837-8797 x701.

Related Links

Strain Gauge Installations for Field Testing

iTestSystem Tip: Strain Gauge Rosette Analysis

Wireless Strain Measurements with iTestSystem, LabVIEW, and Arduino