Pump Motors with Health Monitoring Sensors

Predictive Maintenance with Amazon Monitron Sensors

ITM’s study of Amazon’s Monitron Sensors reveals cost-effective options for industrial monitoring.

On the heels of revolutionizing online shopping, Amazon may now be rewriting the rules of predictive maintenance for industrial equipment.

The engineers at Integrated Test & Measurement have begun testing Amazon’s new AWS Monitron Sensors. Our research has revealed some compelling findings:

- Predictive maintenance may now be within nearly everyone’s grasp at a fairly inexpensive price point.

- Clients who are paying maintenance crews or outside firms to walk the factory floor to spot check high-value assets for potential failures could realize significant savings using this technology.

- With Amazon Monitron Sensors, businesses can harness the power of predictive maintenance, optimize operations and reduce costs.

What are Amazon’s Monitron Sensors?

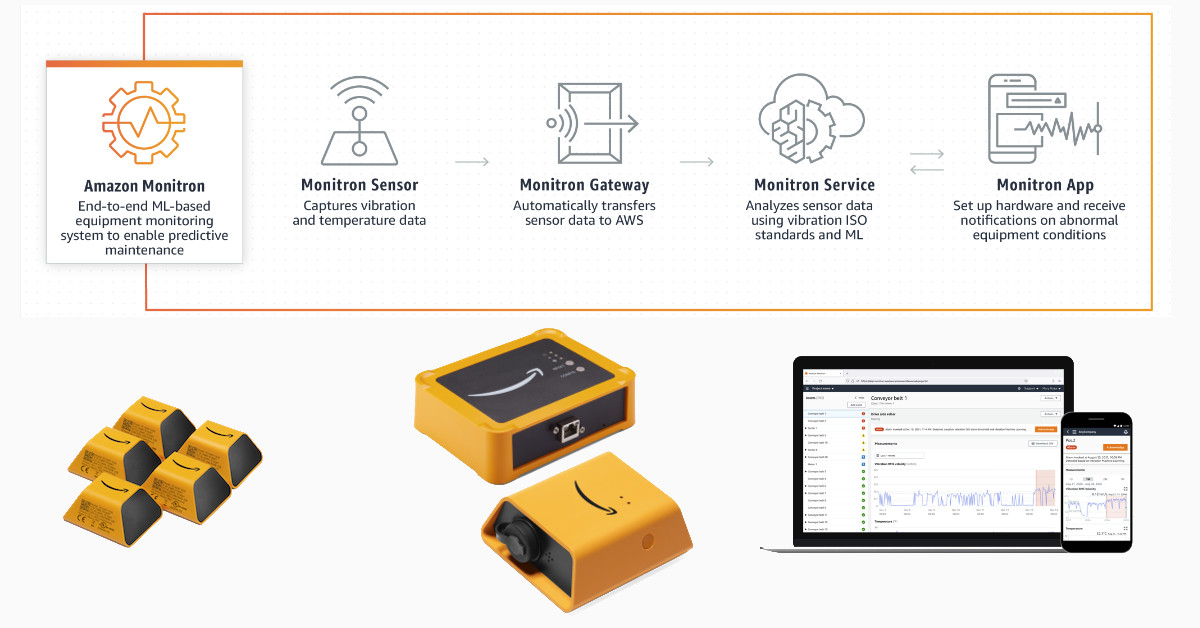

Amazon Monitron is an end-to-end system. It uses machine learning to detect abnormal conditions in industrial equipment. This enables predictive maintenance.

These compact wireless units have a built-in triaxial accelerometer and temperature sensor. They are relatively inexpensive and enable the real-time collection and analysis of data.

Measuring only a couple of inches in width and height, the sensors can be easily deployed on a wide range of critical assets such as pumps, motors, gearboxes and much more, said Ryan Welker, ITM engineer and vice president of operations. Welker is leading a trial study of the devices to detect vibration on equipment in an industrial setting.

Amazon Monitron Equipment Monitoring Components

Welker explained that the AWS units take a data snapshot once an hour and can notify maintenance teams if a critical asset exceeds vibration or temperature settings.

Why is this important?

In the rapidly evolving landscape of technology, companies are constantly seeking innovative solutions to optimize their operations and reduce maintenance costs. Amazon’s Monitron sensors may well revolutionize the field of predictive maintenance, offering a cost-effective and efficient way to monitor critical assets.

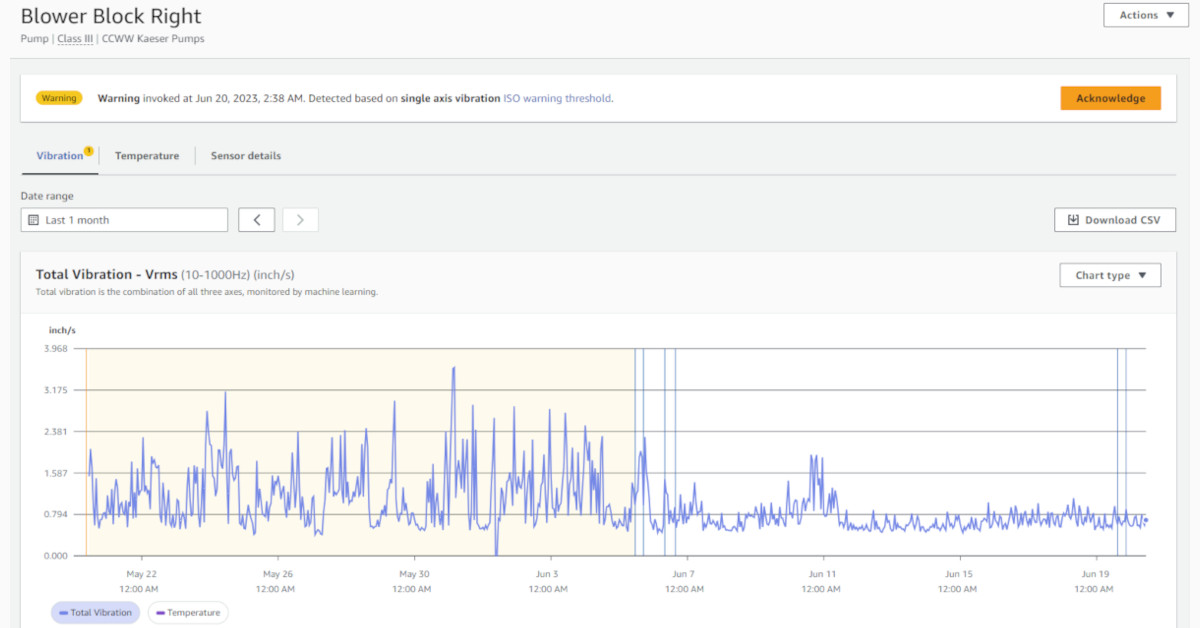

Predictive Maintenance Dashboard for a Blower

At ITM, we can now leverage the power of Amazon’s Monitron sensors, combining our expertise and services to provide comprehensive solutions that ensure optimal performance and prevent costly breakdowns.

Seamless Integration and User-Friendly Interface

ITM specializes in the seamless integration of all types of sensors into your existing infrastructure. In this case, each Monitron sensor is accompanied by a wireless gateway that enables communication via Bluetooth.

By connecting the gateway to the AWS cloud, data can be securely monitored and analyzed. The comprehensive desktop and mobile applications provide an intuitive interface for monitoring, analyzing and troubleshooting. Users receive instant notifications on their mobile devices, allowing maintenance personnel to swiftly address any arising issues.

Predictive Maintenance at Your Fingertips

The sensors capture data at regular intervals, allowing for the establishment of baseline vibration levels based on international standards. By continuously monitoring vibrations and comparing them to established thresholds, the sensors can detect anomalies and trigger alarms in real-time. These alarms alert maintenance personnel to potential equipment failures, enabling proactive maintenance and reducing downtime.

Specializations

Our experts specialize in Amazon Monitron, predictive maintenance, asset failure prevention, seamless sensor integration, data analysis and troubleshooting, anomaly detection, real-time alarms, downtime reduction, maintenance cost reduction, temperature monitoring, vibration detection, industrial asset monitoring, maintenance sensors, predictive maintenance technology, predictive maintenance sensors and real-time data collection.

ITM’s Expertise and Ongoing Support

At ITM, we pride ourselves on being at the forefront of cutting-edge technology and offering comprehensive support, enabling you to stay ahead in an increasingly competitive industrial landscape. Our team of skilled professionals is dedicated to assisting you throughout the entire process, from sensor installation to setup and ongoing support. We understand the unique needs of your business and can tailor Monitron solutions to suit your specific industry and asset requirements.

For more information about our predictive maintenance services and tools, contact ryan.welker@itestsystem.com or josh.fishback@itestsystem.com via email or phone @ (844) 837-8797.