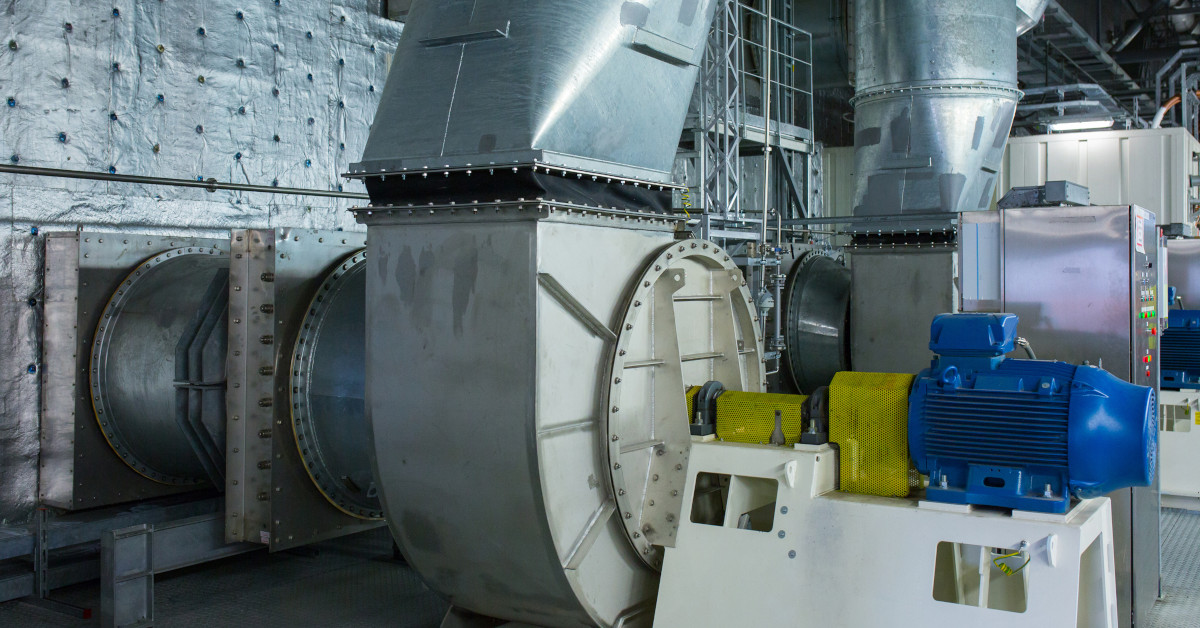

Industrial Fan

Troubleshooting Mechanical Failures in Power Boilers: The Role of ITM Engineers and Operating Deflection Shape Analysis

At Integrated Test & Measurement (ITM), our commitment to innovative engineering solutions is exemplified through our expertise in Operating Deflection Shape (ODS) analysis. Recently, our engineering team undertook a challenging project to troubleshoot and resolve mechanical failures in a power boiler Induced Draft Fan. This blog post highlights the critical role of ITM engineers in employing ODS analysis to diagnose and address these complex issues.

What is Operating Deflection Shape (ODS) Analysis?

Operating Deflection Shape analysis is a sophisticated diagnostic tool used in the field of mechanical engineering to visualize and analyze the motion of machines or structures under operational conditions. By measuring and mapping the vibrational patterns, ODS provides a clear picture of how a component moves and deforms, thereby helping to identify the root cause of mechanical failures.

Modal testing (bump tests) to identify the natural frequencies of the structure/system are typically performed to along with the ODS. In the design phase, modal analysis helps in ensuring that the structure’s natural frequencies are away from the operational frequencies. ODS can then validate this in the real world, ensuring the design performs as expected under operational conditions.

The Engineering Challenge:

Our client faced recurring issues with their power boiler’s Induced Draft Fan, a crucial component for maintaining the boiler’s efficiency and safety. The fan experienced unusual vibrations and noise, leading to concerns about potential failure and downtime.

ITM’s Approach:

Our team of skilled engineers approached the problem methodically:

- Data Collection: We used state-of-the-art sensors and data acquisition systems to capture the fan’s vibrational data while in operation.

- Analysis: Utilizing advanced ODS analysis software, we processed the collected data to create a visual representation of the fan’s deflection patterns.

- Identification of Problem Areas: The ODS analysis revealed specific areas where abnormal vibrations were occurring, which were not apparent during routine inspections.

- Root Cause Analysis: We correlated the ODS data with the fan’s design and operational parameters, leading to the identification of potential causes such as imbalance, misalignment, or structural weaknesses.

Solution and Implementation:

Based on our findings, we recommended a series of corrective actions:

- Balancing and Alignment: Adjustments were made to correct the imbalance and misalignment identified in the fan.

- Structural Reinforcement: We suggested modifications to the fan’s supporting structure to mitigate the effects of identified weak points. Our engineers used FEA modeling and simulations to make sure the fix we suggested corrected the vibration issue and did not add other issues.

- Continuous Monitoring: We implemented a continuous monitoring system for early detection of any future issues.

Results:

Post-implementation, the Induced Draft Fan showed significantly reduced vibrations and noise levels, leading to improved operational efficiency and reduced risk of downtime.

Conclusion:

This project showcases ITM’s expertise in applying sophisticated engineering techniques like ODS analysis to solve real-world problems. Our commitment to technical excellence and innovative solutions remains the cornerstone of our approach to every challenge.

For more information about Operating Deflection Shapes (ODS) or our Engineering and Testing Services, contact Mark Yeager at (844) 837-8797 x701.