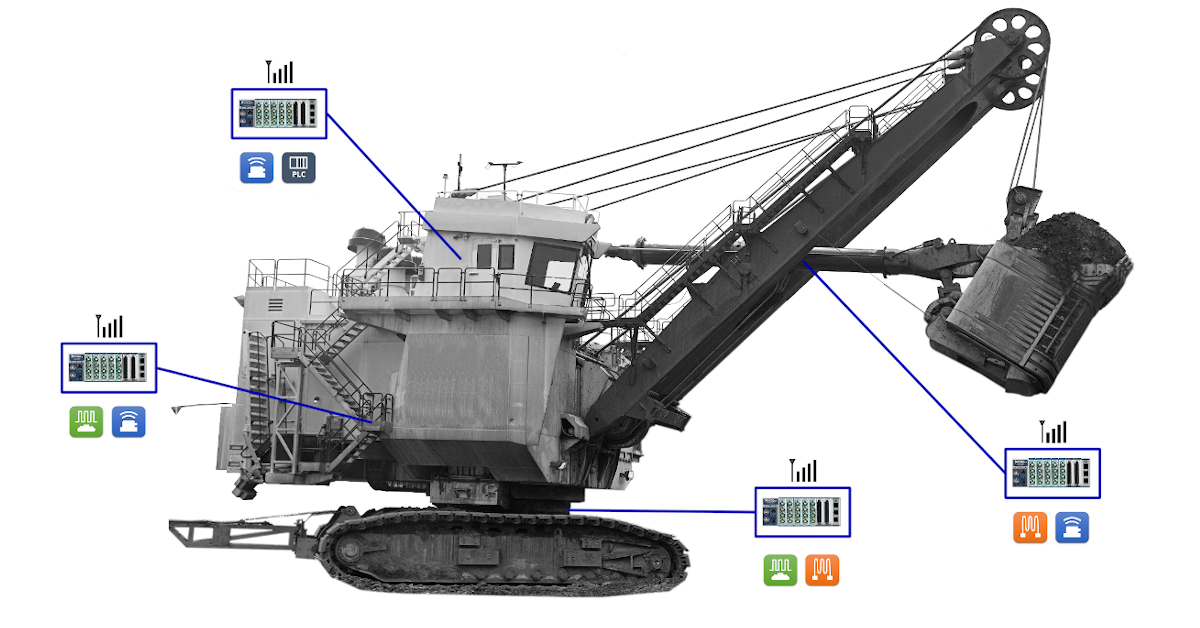

Distributed Embedded CompactRIO Devices monitor structural and vibration health.

IIoT – Industrial Internet of Things

ITM Engineers Help Customers Get Machine Condition Measurements into AWS and Microsoft Cloud Databases

The Industrial Internet of Things (IIoT) is a network of intelligent edge devices and internet technologies in industrial settings, such as manufacturing plants, power plants, and transportation systems. These devices and systems collect and share data, which can be analyzed to improve efficiency, productivity, and safety. Examples of IIoT applications include predictive maintenance, remote monitoring, and automated control systems. The goal of IIoT is to bring the benefits of connectivity and data analysis to traditional industrial environments, to help optimize production and improve overall performance.

How can we help connect to your remote industrial devices, machinery and processes that monitor structural health, usage, and condition to the IIOT?

Integrated test and measurement (ITM) can help with IIoT integration in several ways, specifically when it comes to embedded CompactRIO programming, AWS webservice integration, gearbox vibration, pump vibration, gear mesh frequency, bearing defect frequencies, and structural strain from lifting and during normal operation:

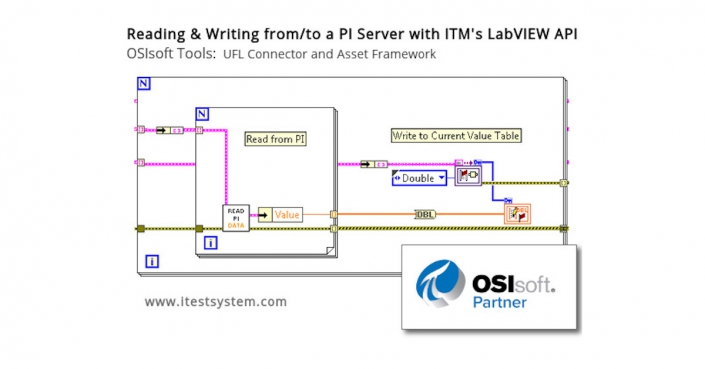

- Embedded CompactRIO programming: Our LabVIEW Architects have a wealth of experience programming CompactRIO embedded systems, which are used in many IIoT applications. This can help to create custom control and monitoring systems that can be integrated with other IIoT devices and systems.

- AWS webservice integration: Our software engineers can integrate edge devices, including the CompactRIO, with AWS webservices, which can be used to collect, store, and analyze data from IIoT devices and systems. This can help to create scalable, cloud-based solutions for IIoT applications.

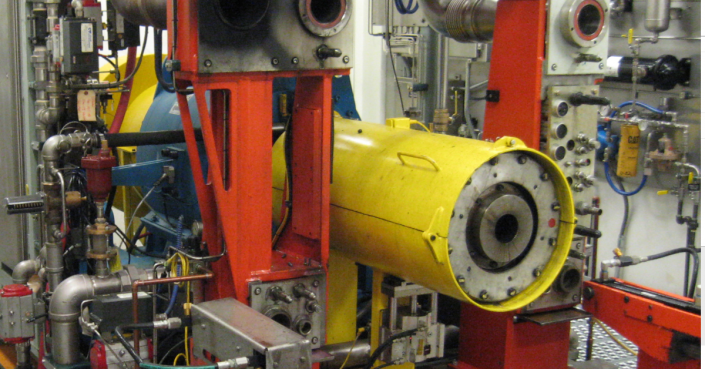

- Vibration Monitoring: Our iTestSystem software can be used to monitor the vibration of gearboxes, pumps and other rotating machinery in real-time, which can help identify issues such as misalignment, imbalance, or wear and tear. This can help to predict potential failures and schedule maintenance before they happen.

- Structural Strain: iTestSystem can also be used to monitor the structural strain of equipment during lifting, maneuvering and normal operation, such as cranes, forklifts and other heavy equipment. This can help to ensure that equipment is operating safely and within design limits and can also help to predict potential equipment failures and schedule maintenance before they happen.

Overall, ITM Engineers can be used to validate, monitor, predict, and control the performance of IIoT devices and systems, specifically by using embedded CompactRIO programming, AWS webservice integration, gearbox vibration, pump vibration, gear mesh frequency, bearing defect frequenciesand structural strain from lifting, maneuvering and normal operation.