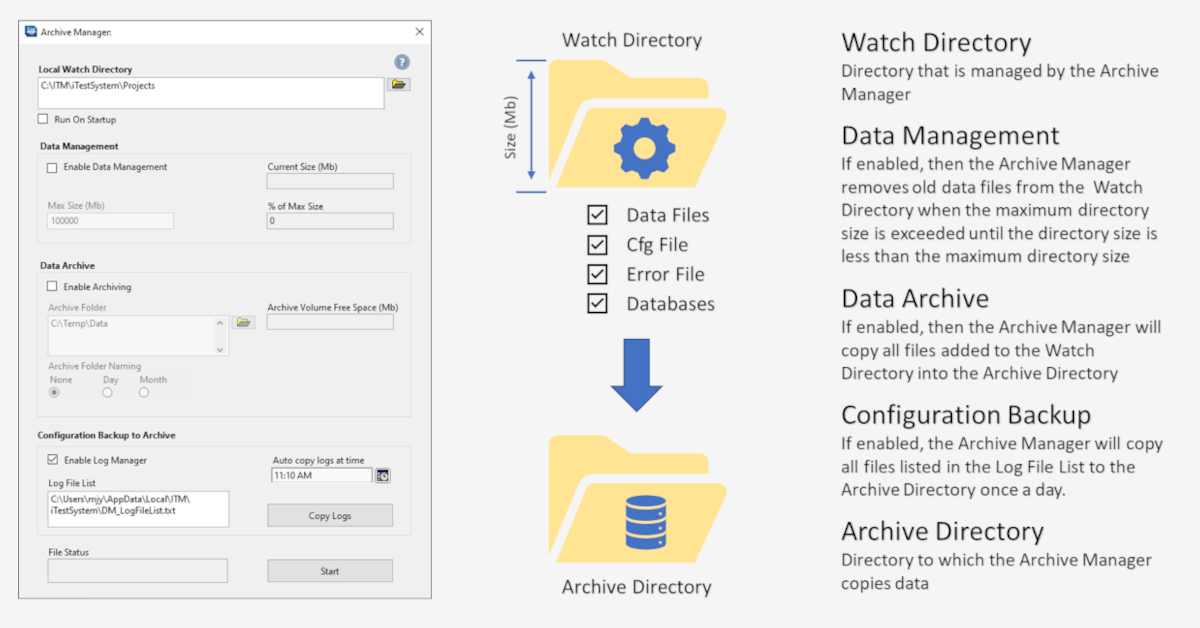

iTestSystem Application: Archive Manager

Managing data from autonomous data acquisition systems that generate megabyte and gigabyte data files can be a challenge. iTestSystem’s Archive Manager application simplifies this data collection challenge by allowing users to configure a local directory as a data file FIFO and a separate directory (usually on a USB drive) as a data archive.

When enabled, Archive Manager solves two problems common to DAQ systems: system crashes due to a full hard drives and removeable drive (USB/network drive) management. The Archive Manager allows users to set a limit on the amount of data stored in a specific directory. It monitors this directory and removes older files to accommodate new data files (data file FIFO). This application keeps track of all data files removed from the watch directory and all files moved to the archive directory. This allows users to swap removeable drives on the fly without duplicating data files in the archive or interacting with the DAQ system’s HMI.

Another feature of the Archive Manager application that ensures autonomous DAQ system stability is the configuration backup process. When enabled, the configuration backup service periodically copies all files added in the log file list to the archive directory. Backing up files like the iTestSystem configuration file allows test engineers to keep track of setup changes that occur during a test or data logging project and restore previous configurations.

For more information about the iTestSystem Archive Manager or iTestSystem, contact Chase Petzinger via email at chase.petzinger@itestsystem.com.