Tag Archive for: Wireless Strain

Transform Your Silo into a Smart Weighing System with IoT and Strain Gauge Technology

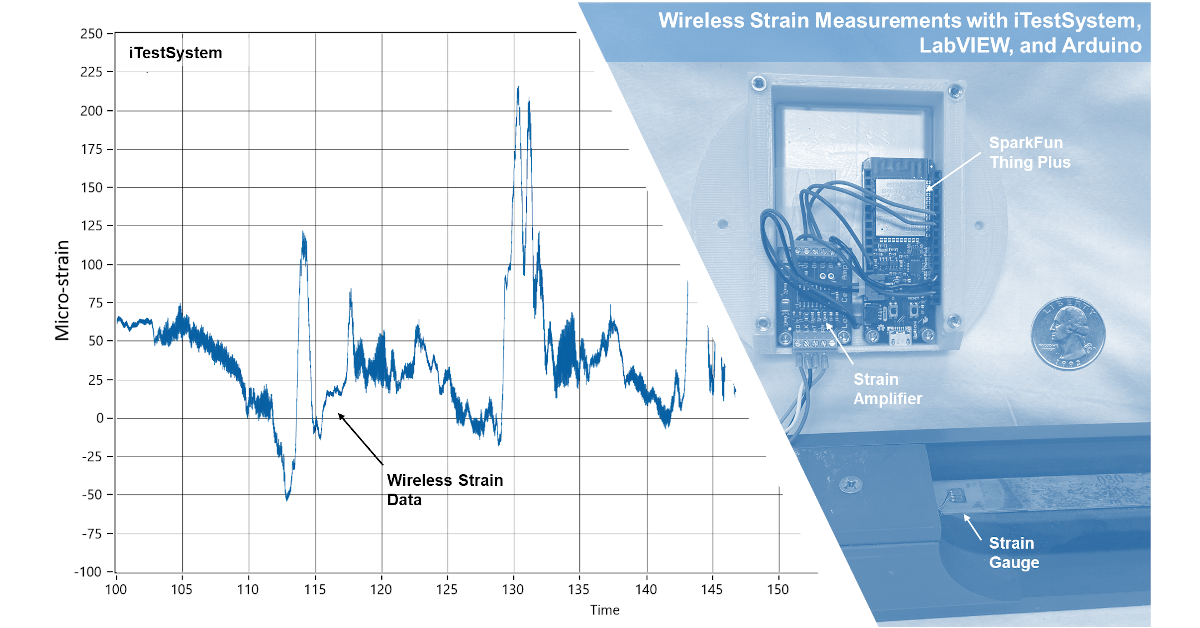

in Blog Posts, Energy, Power Generation, Pulp & Paper/by Mark YeagerWireless Strain Measurements with iTestSystem, LabVIEW, and Arduino

in Blog Posts/by Mark Yeager

On a recent project, one of our engineers needed to measure structural strain at several locations on mobile lifting equipment while in operation. Since the strain measurements were distributed and mobile, a wireless internet of things (IOT) solution was required. This blog describes the steps and tools we used to integrate our solution into iTestSystem and LabVIEW™.

What we offer

Are you looking for expert assistance with strain gauging, a wireless IOT solution or free custom engineering software platform that enables you to organize, acquire, view, and analyze data?

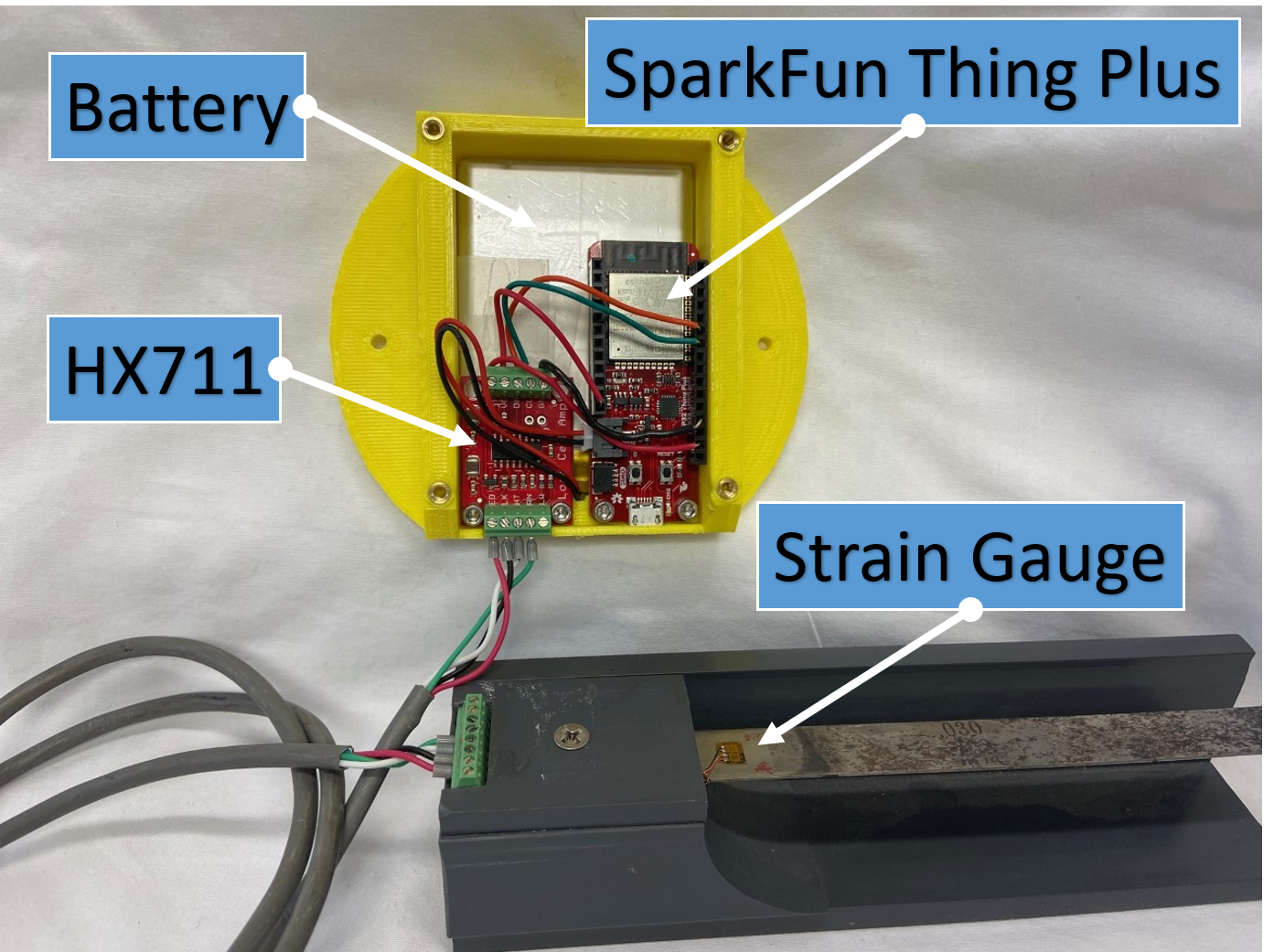

One of the wireless devices that we evaluated to monitor strain was a SparkFun Thing Plus (ESP32 WROOM) with a Load Cell Amplifier (HX711). The SparkFun Thing Plus uses the Espressif ESP32 Wi-Fi and Bluetooth MCU. It accepts a variety of digital interfaces including high-speed SPI, UART, I2S, and I2C. The HX711 load cell amplifier accepts four-wire Wheatstone bridges and outputs 24-bit data at either 10 Hz or 80 Hz. The digital signal from the HX711 was connected to a GPIO pin and clock pin on the SparkFun Thing Plus. We used a Lithium Ion 2Ah battery to power both devices.

Figure 1: Wireless Strain Prototype Connected to a 4-Wire Bending Bridge

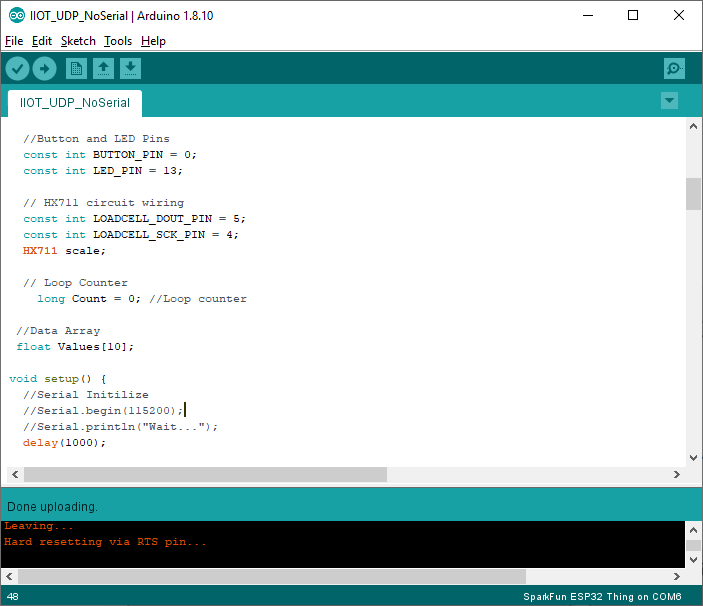

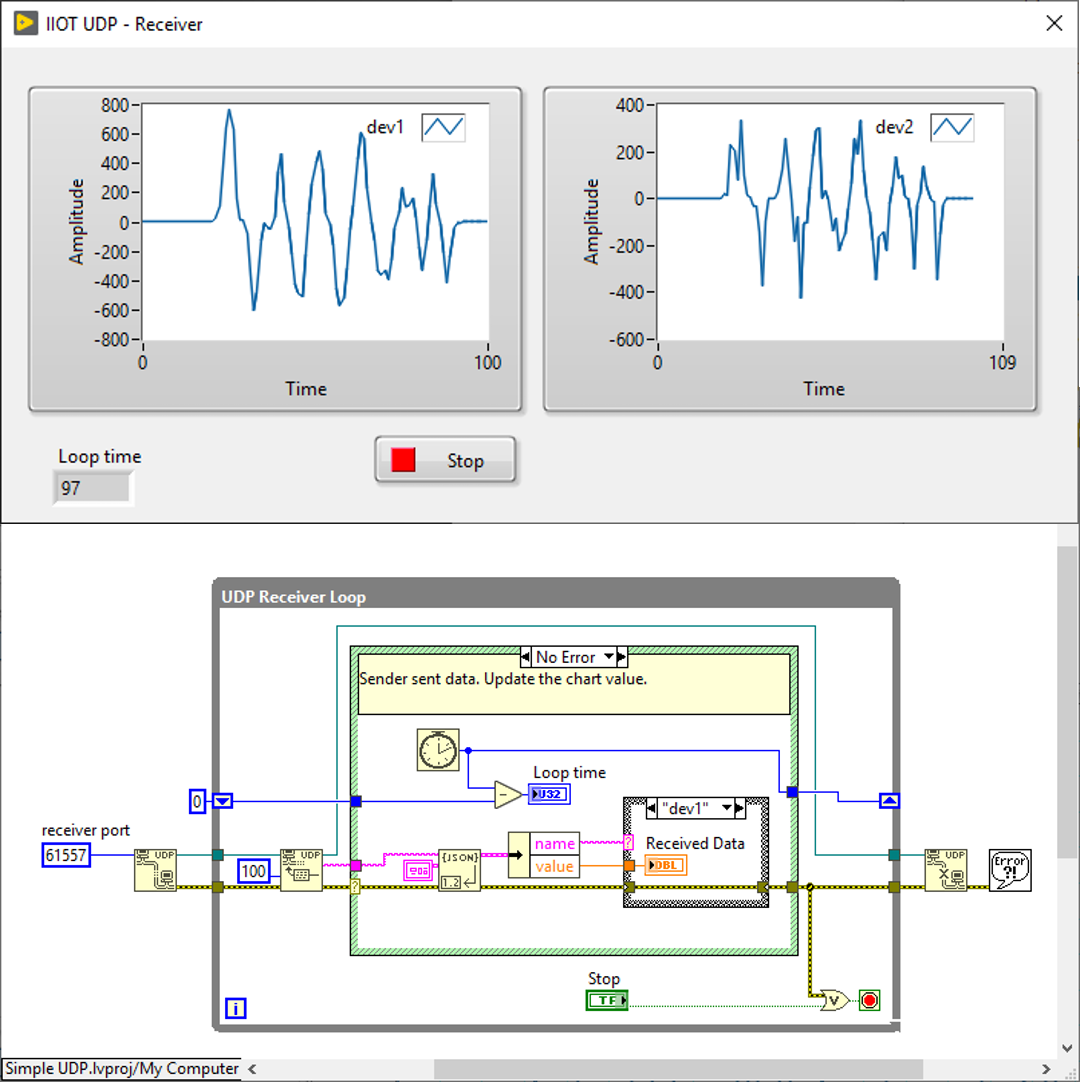

After making the connections and installing the device in a 3D printed case for mobility testing, our development engineer programmed this device using the Arduino IDE. Our wireless strain prototype was programmed to auto connect to a Wi-Fi network and output device ID, tag names, and data values via UDP or Webservice. We chose UDP because we only needed the latest strain/load values. Bundling the device ID with the strain data would allow iTestSystem to collect data from multiple devices. To test the wireless strain prototype and develop the UDP interface for iTestSystem, we modified the Simple UDP LabVIEW example vi.

Figure 2: Arduino IDE with Example Program

Next, we integrated the wireless strain prototype into iTestSystem by adding a new communication class into the existing iTestSystem IOT Communication utility. This new class allowed the utility to read the specific UDP data type associated with our prototype and output data to a shared variable. Shared variables can be logged to disk and analyzed with iTestSystem alongside other machine data.

Figure 3: Simple UDP LabVIEW™ Code

For more information about this application, iTestSystem, or our strain gauging services, contact Mark Yeager via email at mark.yeager@iTestSystem.com or phone @ 1.844.837.8797 x701.

ITM Uses 3D Printing to Improve Wireless Torque Measurement Designs

in Announcements, Blog Posts, Video/by Tim Carlier

One of the ways ITM sets itself apart is that our engineers don’t flinch when it comes to finding creative ways to make tough measurements.

For example, as you can see in this video, we have begun using our in-house 3D printer to customize plastic collars — embedded with sensors and transmitters — which allow us to wirelessly measure torque on rotating machinery.

In this example, we’re recording a signal as the drill bit enters the wood, but the same solution allows us to model and print a larger fixture to measure the stresses on an industrial drive shaft or other piece of rotating equipment.

Where once we might have turned to an area machine shop to mill a similar type collar, we can now model an even more precise tool and print it out overnight — saving valuable time and at a fraction of the cost.

3D Printing is just one more example of how ITM uses cutting-edge tools and new technology to solve problems.

— ITM President Tim Carlier

CONTACT INFORMATION

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.