ITM Announcements

The Announcement category contains announcements related to ITM’s testing services, LabVIEW programming, Test & Measurement Hardware, Boiler Monitoring Systems, and iTestSystem applications.

Happy Holidays 2021

in Announcements, Blog Posts/by Ryan Welker

A special thanks to all of our customers for helping make 2021 another successful year. We want to wish you and your family a joyful holiday season with peace, health, and happiness in the coming year!

Integrated Test & Measurement

iTestSystem 20 Coming Soon!

in Announcements, Blog Posts, LabVIEW Channel/by Mark Yeager

Coming Soon! iTestSystem 20.0

When: January 2022

The latest version of ITM’s engineering measurement software platform will make gathering data easier and more affordable than ever.

For more information about iTestSystem, contact Chase Petzinger at (844) 837-8797 x704 or via email at chase.petzinger@itestsystem.com.

Excellence in Impact Award

in Announcements, Blog Posts/by Mark Yeager

ITM’s Resilience Recognized with County’s ‘Excellence in Impact Award’

Like most small businesses, Integrated Test & Measurement spent the last year weathering a storm of uncertainty due to COVID-19. How would the company both stay safe and stay in business?

The answer to that crucial question and the actions that ITM took during the pandemic were recognized on Feb. 12 when the Milford, Ohio, engineering firm was named the winner of the Excellence in Impact Award by The Ohio Small Business Development Center at the Clermont Chamber of Commerce, presented by Duke Energy.

The Excellence in Impact Award is given annually to one Clermont County business that demonstrates an outstanding contribution to the local economy, and ITM President Tim Carlier was thrilled to have his company recognized, particularly after the challenging year his team has endured.

The Excellence in Impact Award is given annually to one Clermont County business that demonstrates an outstanding contribution to the local economy, and ITM President Tim Carlier was thrilled to have his company recognized, particularly after the challenging year his team has endured.

As the pandemic pressed its way into Ohio and the governor declared a stay-at-home order in March of 2020, ITM faced a series of massive challenges. The company relies heavily on travel and on-site work to complete complex testing and analysis in industries such as aerospace as well as pulp and paper. The year 2020 was supposed to be a year for growth, yet the pandemic threatened their entire business model.

Major clients who had been defined as “critical infrastructure” industries by the Department of Homeland Security were reaching out to see if ITM intended to meet its obligations. Rather than withdrawing and playing it safe, Carlier challenged his team to lean in, learn all they could, then do the work as they always had. He knew their success would depend on their resiliency.

“While this COVID 19 virus is complicated, my position is simple,” he said in an email to the team. “ I am working hard to keep everyone safe by mitigating employees’ risk for exposure and staying in business. I cannot do this alone, I need your help.”

They took an engineer’s approach to the virus and developed an exhaustive document titled “ITM COVID-19 Operating Response Guidelines.” They learned they could work from a distance effectively when needed using Microsoft Teams. After a short lapse, travel was back on, but they would need to be more creative. Long car rides replaced flights, and teams even broke into multiple vehicles to assure safety. They scoured local stores for masks, paper towels and sanitizer and found themselves grateful when boxes of basic supplies arrived from both the state and Clermont Chamber of Commerce.

Ultimately ITM kept its obligations to its clients, and was even able to continue on a growth trajectory in 2020 thanks in part to the Paycheck Protection Program (PPP). In fact, the team of 7 actually added a full-time position and two co-op students, plus they doubled down on marketing efforts, which is now leading to even more opportunities in 2021. Carlier is incredibly thankful that the team went above and beyond to deliver during the pandemic, and he points out that along the way they learned a great deal about themselves and realized when tested, they can, in fact, emerge stronger.

More About ITM

ITM is a structural test & measurement engineering service and software company that focuses on three vertical spaces: Industrial monitoring, testing services, and its proprietary test software iTestSystem. ITM was founded by Tim Carlier in 2001 to help companies reduce costs and improve efficiencies in their product development, manufacturing, and production activities. ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauge (gage) installations, and data analysis solutions to clients on five continents.

Of specific note is ITM’s work with NASA and the aerospace industry as well as the firm’s patented technology in boiler monitoring systems. These advances and specifically ITM’s Sootblower Fouling Detection System (FDS) allow for substantial efficiencies inside black liquor recovery boilers where operators are now able to conserve as much as 5% of a boiler’s total steam. Not only does this advance in boiler efficiency carry an enormous environmental impact by reducing carbon emissions, but the value of steam savings can also exceed more than a million dollars a year at plants where it is adopted.

Link: Clermont Chamber of Commerce News Release

Silo Load Monitoring

in Announcements, Blog Posts, Civil | Infrastructure, Energy, Power Generation, Pulp & Paper/by Ryan Welker

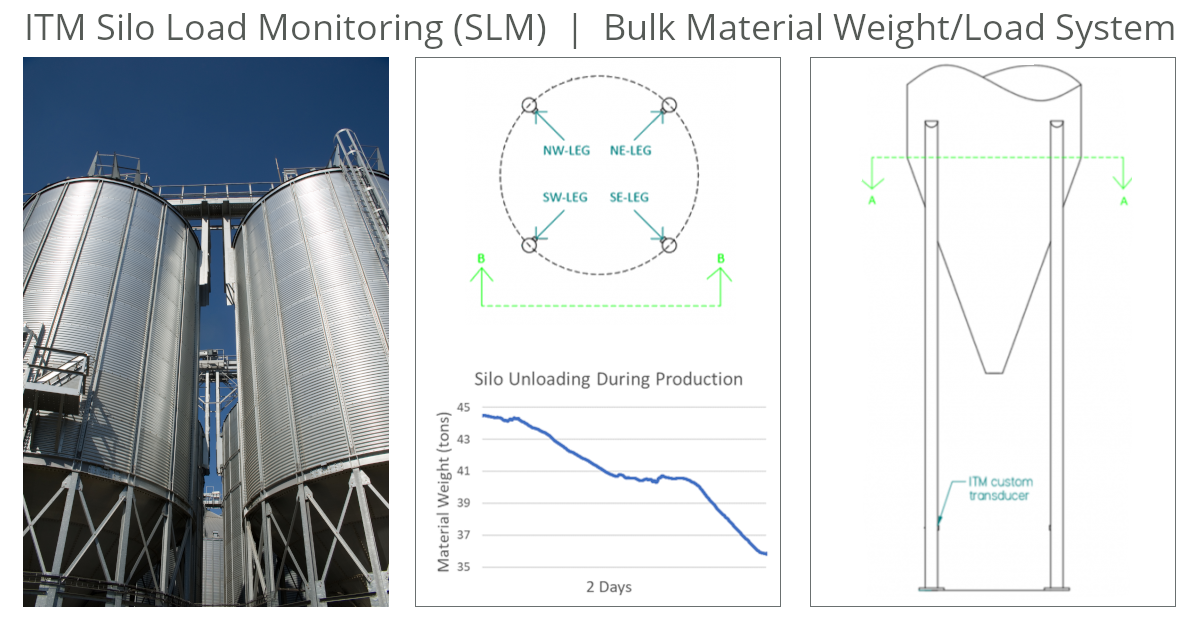

Plant operators need to continuously measure bulk material levels/weight in their silos and hoppers to ensure their processes are running safely, efficiently, and without bottlenecks. Measuring these levels allows operators to automate vessel filling, verify material consumption, and prevent overfilling.

What we offer

ITM provides its customers with a variety of structural load monitoring systems. Using strain gauge based transducer technology, ITM can design and implement a real-time system to continually monitor load responses of the supporting members on an array of structures.

Strain gauge based measurements are more accurate and typically less expensive than load cell retrofitting. The addition of a monitoring system can also reduce the risks associated with manual measurements including contamination of product and, more importantly, injury to a worker.

How do you measure bulk material levels/weights in silos and hoppers?

The two ways to measure bulk material quantity in silos/hoppers are level indicators (laser, ultrasonic, radar) and weight measurements (load cells, strain gauges). Weight measurements are more accurate, safer to install, and can be installed during operation. Of the types of weight measurements, ITM prefers to implement strain gauge-based solutions since they do not require structural modification of the vessel.

An ITM silo monitoring system typically consists of weatherproofed strain gauges for each silo leg and a NI CompactRIO embedded controller to acquire data, process signals, and output results. Systems are scalable to accommodate all the silos at the plant.

The graph above shows a typical trend of real silo data during unloading. Weight levels are sent directly to factory DCS systems and historians via common communication protocols like Ethernet/ip and Modbus, or they can be viewed on the system’s webpage or a local/remote workstations and panels.

What are the challenges when measuring bulk material levels/weights?

Most bulk material storage is outside, so temperature and other environmental factors must be accounted for not only in the durability of the equipment, but in the sensor design and data processing. Changes in temperature, wind, and humidity can result in changes to the load path in silo legs. Load changes are account for by instrumenting all or most of the silo legs and selecting the appropriate strain gauge bridge design which results in continuously accurate weight measurements.

While other systems require calibrating the system with known loads (point calibration), ITM calibrates the system using a shunt voltage across the strain gauge bridge. This process automatically calibrates the system and eliminates the requirement of having pre-known material weight added to the vessel.

For more information about silo monitoring, contact Ryan Matthews @ 1.844.837.8797 x706. To see how ITM’s structural load monitoring systems work watch this video below.

Engineering Data Acquisition Tools: cDAQ-9189

in Announcements, Blog Posts/by Mark Yeager

When our engineers go on the road to troubleshoot structural component failures or machine vibration problems, they grab their laptop with iTestSystem installed and Pelican case containing an NI CompactDAQ (cDAQ) chassis and an assortment of C-Series modules, accelerometers, and strain gauges. The cDAQ chassis that they typically use is a cDAQ-9189 ethernet chassis, which is ideal for data logging.

The cDAQ-9189 is an extended temperature TSN enabled 8-Slot Ethernet chassis designed for distributed sensor measurement systems. The chassis controls the timing, synchronization, and data transfer between C Series I/O modules and your laptop. Since the chassis has an integrated network switch and is TSN enabled, measurements from multiple chassis are synchronized by simply daisy-chaining chassis with an ethernet cable.

For more information about the cDAQ-9189, DAQ hardware rentals or iTestSystem, contact Josh Fishback at (844) 837-8797 x705 to assist with your data collection needs.

Analyzing Vibration to Evaluate Sootblower Performance

in Announcements, Blog Posts, Energy, Power Generation, Pulp & Paper/by Tim Carlier

ITM stake holders, we have recently received good news from the US Patent Office. They have recently allowed claims relating to the use of vibration measuring devices to evaluate the operation of a sootblower (US20190041201A1). This allowance strengthens the protection of the sootblower health and fouling detection features of ITM’s Sootblower Fouling Detection (SFD) Technology.

Additional Claims: “A method of evaluating an operation of a sootblower in a boiler system, the method comprising: operating a sootblower having a rotating lance tube; measuring a vibration in the boiler system caused by the operation of the sootblower, wherein the vibration is measured with a vibration measuring device; and analyzing the measured vibration to evaluate the operation of the sootblower.”

US Patent #: US20190041201A1

For more information about ITM’s SFD Technology or other Boiler Monitoring Systems, contact Ryan Welker @ (844) 837-8797 x702

Related Links

- Sootblower Fouling Detection – SFD

- Fouling Monitoring System – FMS

- Hopper Ash Level Thermouple – HALT

Welcome Aboard Zach Strong

in Announcements, Blog Posts/by Ryan Welker

I’m excited to announce that our team is growing with the addition of Zach Strong. After graduating in May of 2020, Zach recently moved from Co-Op to a full-time engineering technician position. Zach’s primary role as an engineering technician is to assist with industrial monitoring solution installations and field testing applications. In addition to his work in the field, Zach works in our instrumentation lab assembling and testing custom control panel assemblies, installing strain gauges on customer components, and building and testing customer monitoring and measurement systems.

We welcome Zach to our team. You can read more about our entire team here.

— Vice President of Operations – Ryan Welker

ITM Winter 2020 Yeti Cooler Giveaway

in Announcements, Blog Posts/by Ryan Welker

Our engineering services department is sponsoring a Yeti Cooler Giveaway. This giveaway runs from January 6th, 2020 to February 28th, 2020. To register for this giveaway and view the official rules click the Register Now button below.

Contact Ryan Welker via email:ryan.welker@iTestSystem.com or phone: 1.844.TestSys x 702 for help with any structural testing, strain gauging, and industrial monitoring applications.

Happy Holidays 2019 from ITM

in Announcements, Blog Posts/by Tim Carlier

May your homes be filled with warmth and your hearts with joy. ITM wishes you a happy holiday season and a new year full of prosperity and adventure!

CONTACT INFORMATION

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.