Roving Accelerometer Impact Tests with iTestSystem

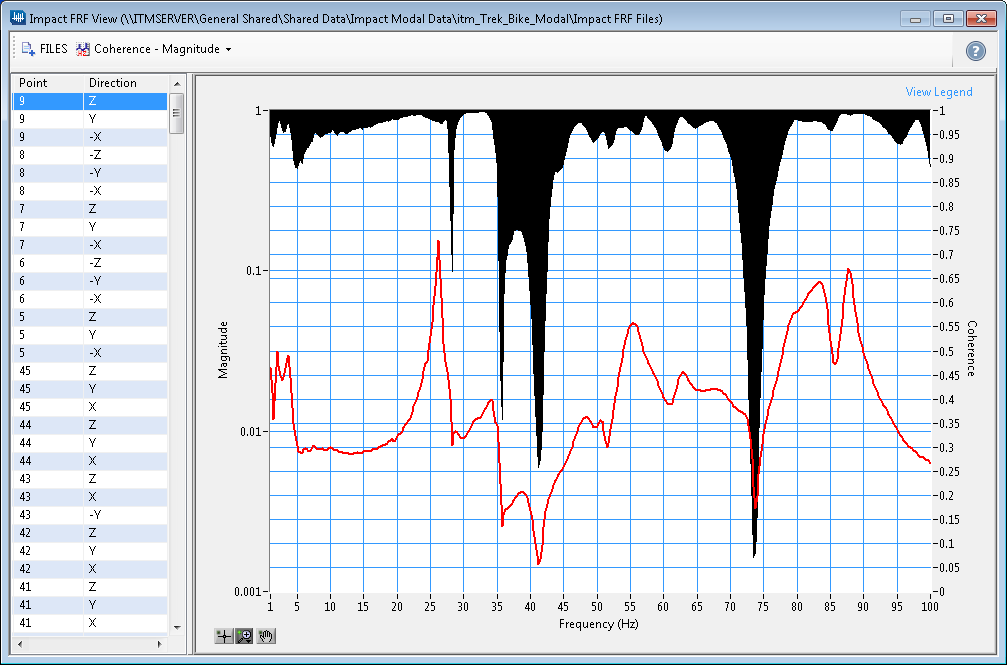

In order to prevent or troubleshoot structural vibration problems, it is important to characterize a structure’s dynamic behavior using both experimental and Finite Element Analysis (FEA) technologies. One method used to identify a structure’s vibration modes is to perform a roving accelerometer or roving hammer impact test. In an impact test, engineers measure the response of a structure from an impulse delivered by a calibrated hammer using tri-axial accelerometers.

Managing impact tests on large structures can be tedious and cost prohibitive, since they require collecting accelerometer responses at hundreds of locations to resolve the vibration motion. Not only do test engineers need to keep track of the locations, they also need to keep track of the orientation that an accelerometer is positioned.

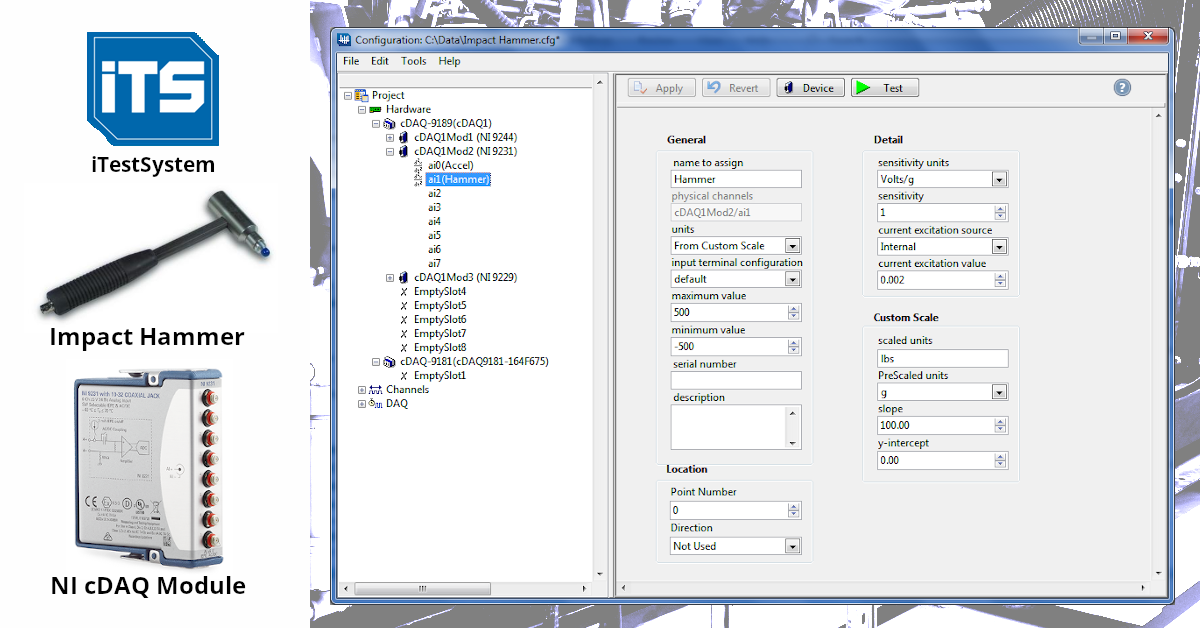

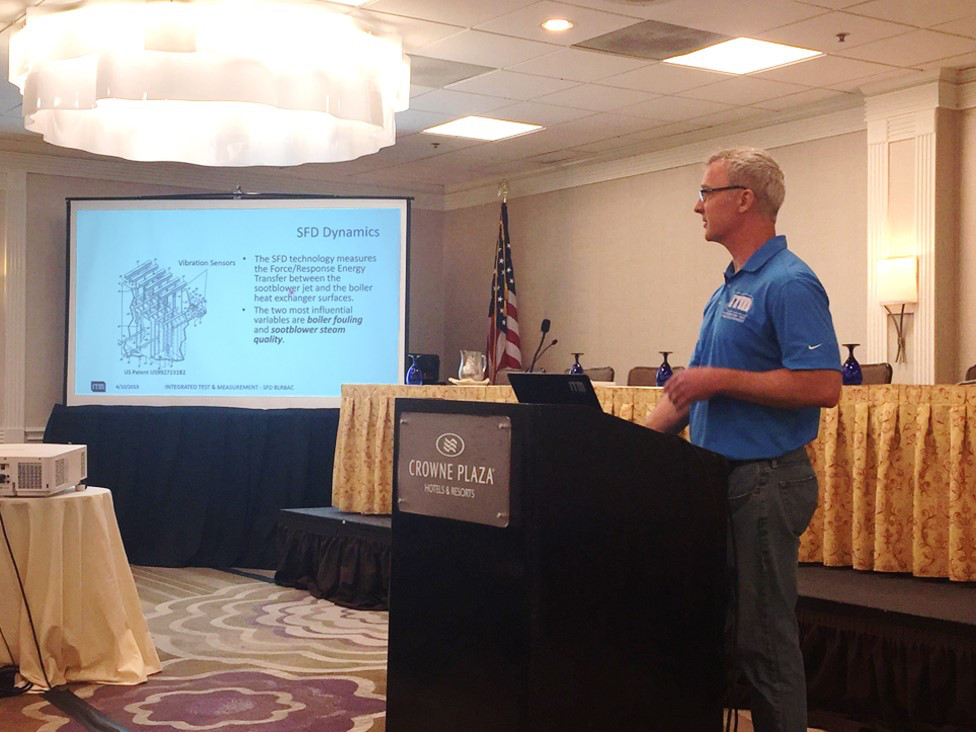

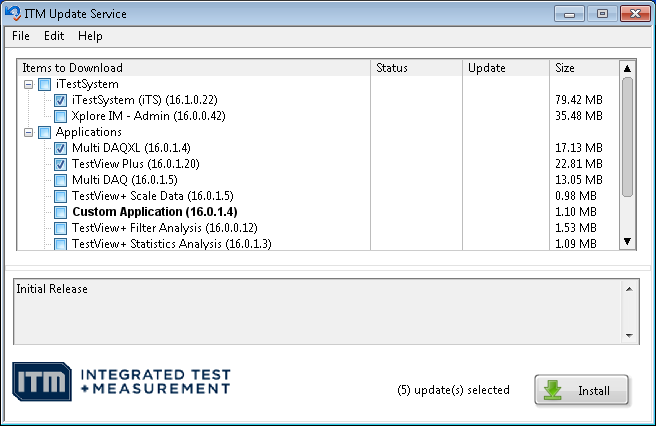

Our test engineers have found that the most efficient and cost effective solution for collecting impact data is to use a National Instruments (NI) cDAQ chassis with either NI-9234, NI-9232, NI-9231 or NI-9230 IEPE modules along with a calibrated impulse hammer and between 3 – 9 tri-axial accelerometers. To collect, manage, and visualize the modal data, our LabVIEW software engineers developed the Impact Test DAQ, FRF Viewer, and 3D Animator applications for our iTestSystem software platform. These applications incorporate tools that our test engineers need to manage and validate the quality of their modal data while in the field.

For more information about impact tests, modal analysis, our iTestSystem Impact Test applications, or to schedule a modal test contact Mark Yeager or Ryan Welker.