When we develop LabVIEW™ applications for our customers, a common request is for a simple, resizable and intuitive user interface (UI) for data visualization. In these cases, we use a tree control and a subpanel. This type of UI functions like a tab control that automatically resizes. The main benefit of using a subpanel is to make your code more modular.

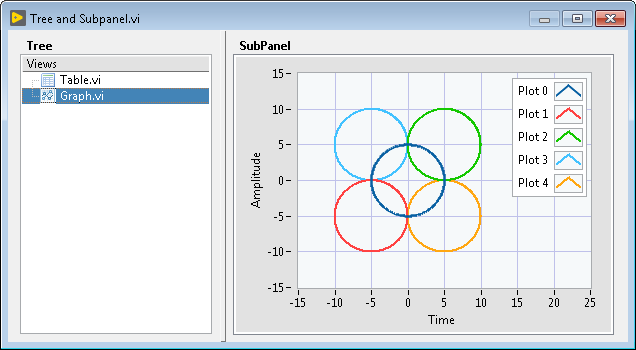

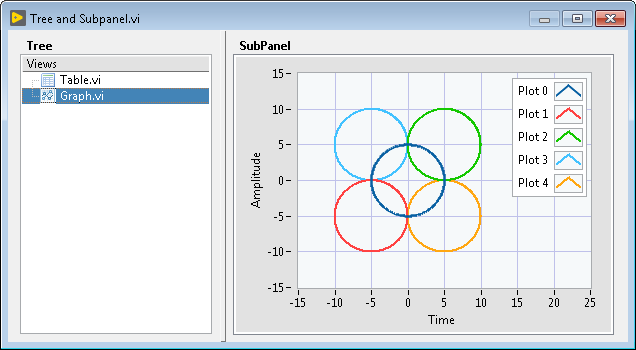

Figure 1: Modern User Interface with a Tree and Sub Panel.

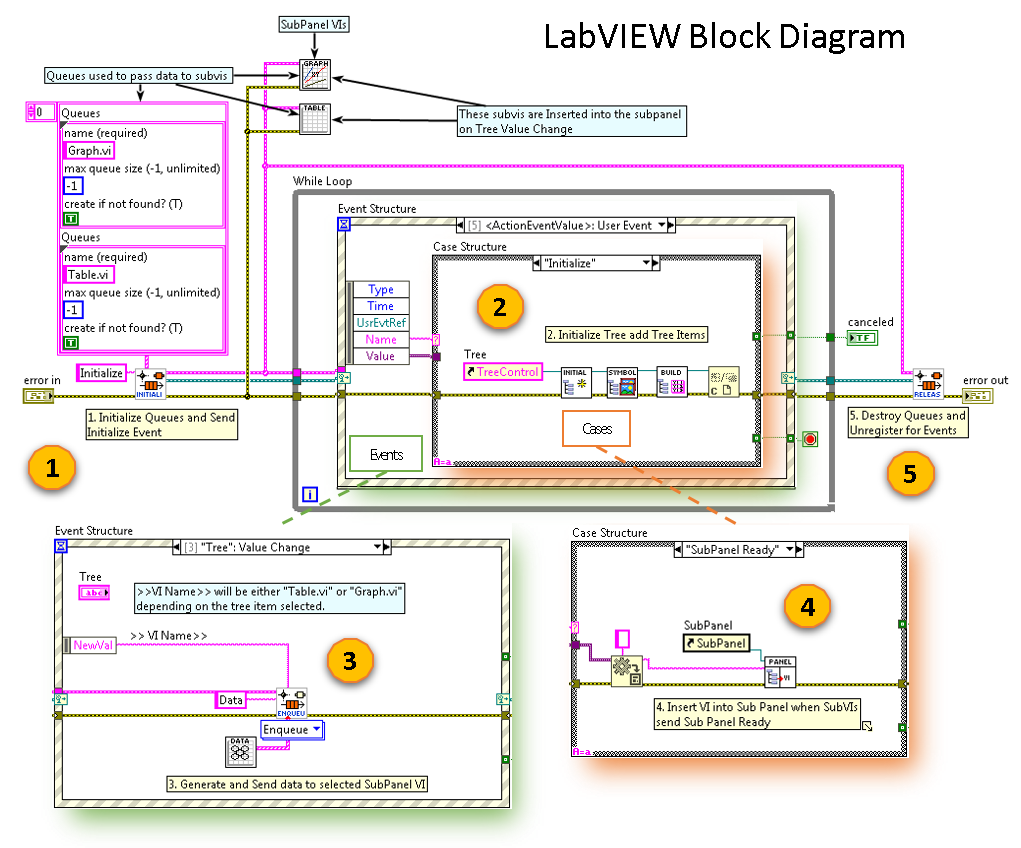

To illustrate the modularity that this type of UI creates, I made an example LabVIEW™ project. The main VI shown above uses a tree control to switch between a VI containing a graph and a VI containing a table. I used our multi-queue event architecture for VI information communication messaging. The image below shows the main VI’s significant functions.

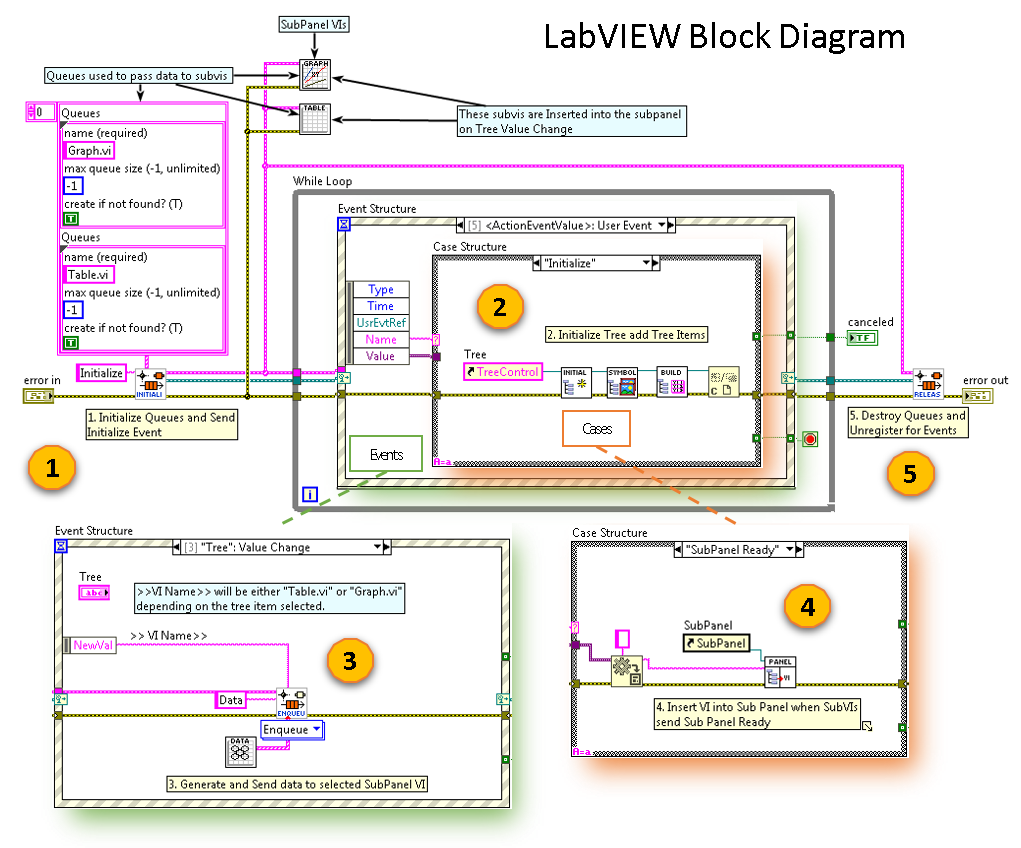

Figure 2: Main VI’s Block Diagram – Significant Functions

The main VI’s functions are listed below.

Functions

- Initialize queues and events and then generate initialize event.

- Initialize tree and add tree items.

- When a user selects an item in the tree, generate data and then send it to the subpanel VI.

- Receive SubPanel Ready event from a subpanel VI and then insert the VI into the subpanel.

- Destroy queues and unregister for events.

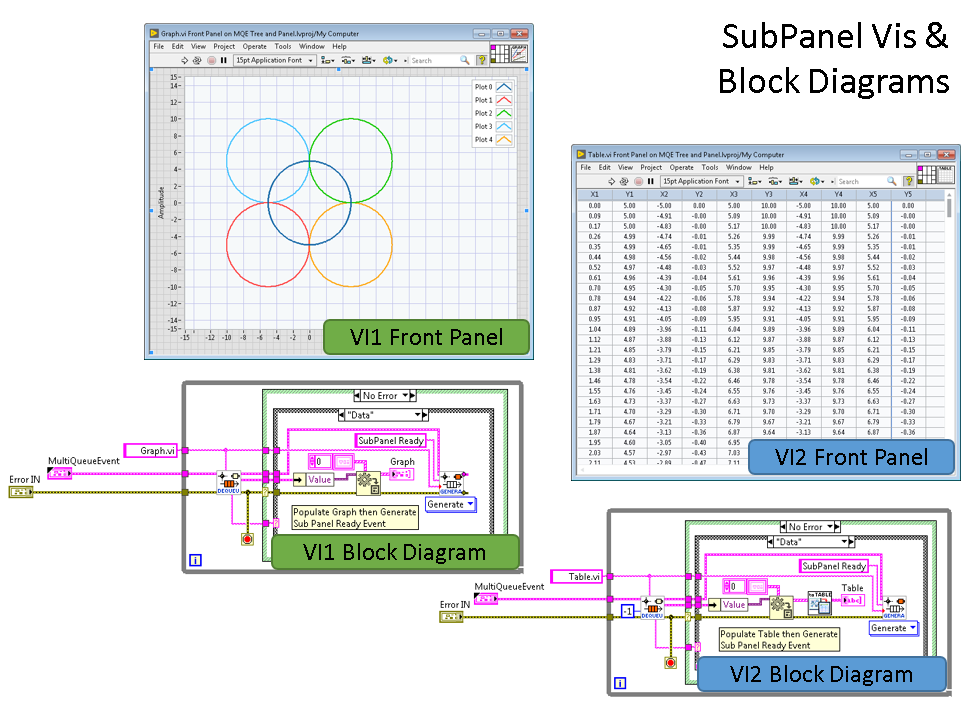

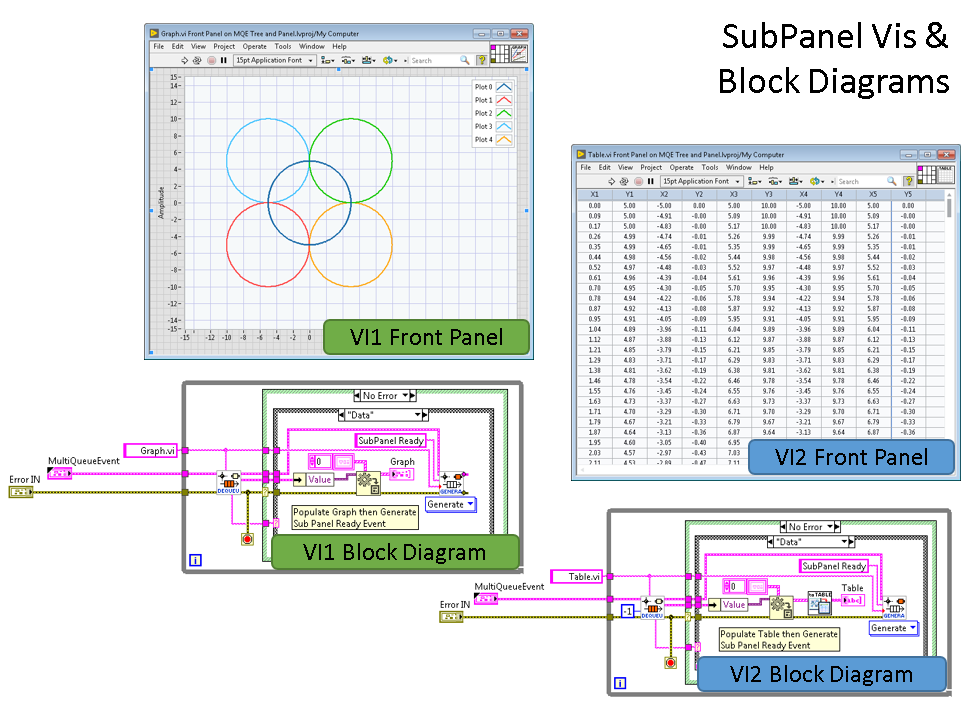

In this example the subpanel VIs are very simple. They populate an indicator (table or graph) and then generate a SubPanel Ready Event. The two (2) subpanel VIs and block diagrams are shown below.

Figure 3: SubPanel VIs: Graph.vi and Table.vi

Contact Information: For more information on this example or our LabVIEW development service contact:

Mark Yeager – Integrated Test & Measurement (ITM), LLC. Email: mark.yeager@itestsystem.com or Phone: 1.844.TestSys

The NI-9202 Voltage Input Module can now be used with the latest version of iTestSystem (16.1). The NI-9202 has excellent flexibility to meet the needs of your applications.

The NI-9202 Voltage Input Module can now be used with the latest version of iTestSystem (16.1). The NI-9202 has excellent flexibility to meet the needs of your applications.

I’m excited to announce that we’ve grown our engineering group with the addition of

I’m excited to announce that we’ve grown our engineering group with the addition of