iTestSystem Application: Notification Service

Get Your Engineering Data When it Counts using ITM’s iTestSystem Software

In a world where we’ve grown accustomed to knowing about important events or crucial information nearly immediately, it may be of little surprise that the architects who build engineering measurement software included powerful notification abilities.

An Amazon package delivery to your doorstep now prompts an email, a text or even a blinking light on your Alexa or Google Assistant.

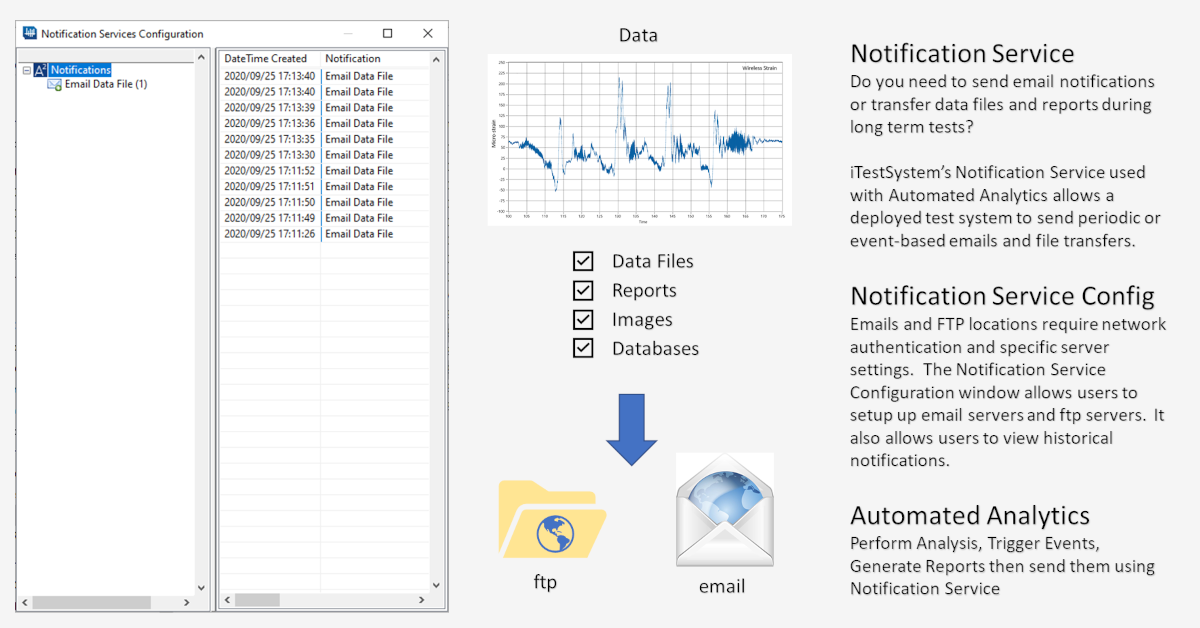

At Integrated Test & Measurement, the engineers behind iTestSystem applied this need-to-know concept to the latest version of their powerful and proprietary data-collection tool. In this blog, a new series by ITM, we’ll share details about iTestSystem’s “Notification Services” feature, which is commonly used to to pass crucial engineering data — think strain and vibration — to those who need it most and just in time.

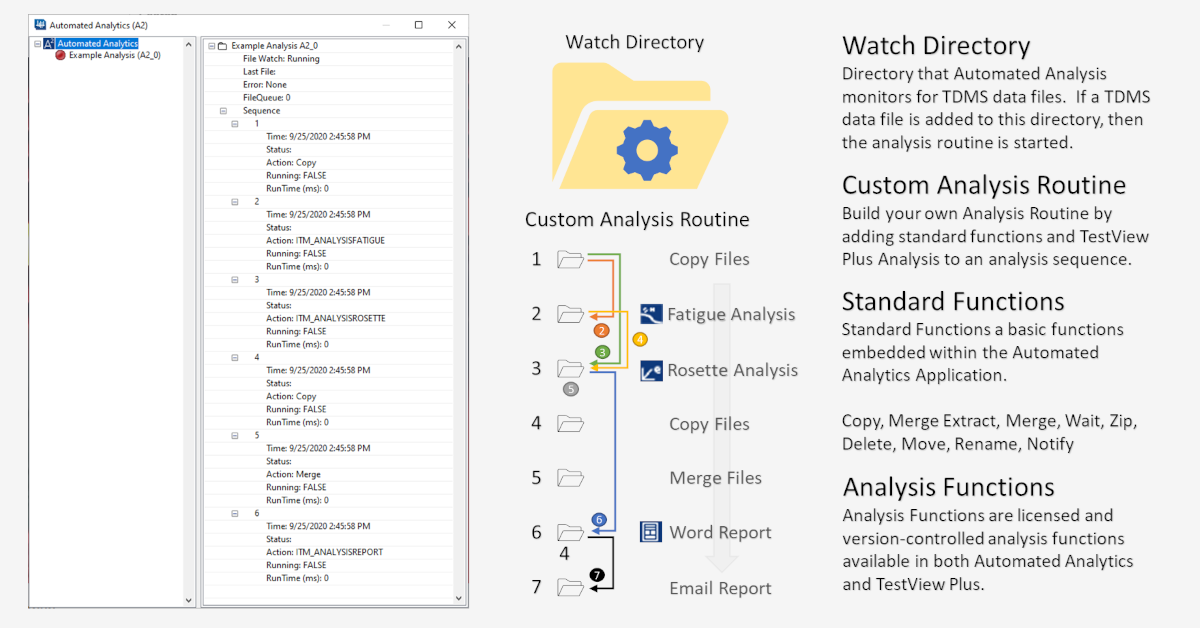

By pairing Notification Services with the Automated Analytics feature in iTestSystem, engineers are able to greatly simplify processes that require hunting down system operation outliers or damaging events. The Automated Analytics application allows users to analyze, build, and send sensor level reports only when specific vibration and strain limits are exceeded. In the end, that leads to a massive time savings. Instead of searching through streams of data files, engineers can easily review the report and download relevant data files from deployed systems for further analysis.

Does your project involve the need to deploy unattended or “black box” data acquisition systems in the field? If so, iTestSystem may be the ideal solution.

Here’s how Notification Services works:

As mentioned above, users can pair the Automated Analytics feature with the power of Notification Services, an iTestSystem feature that allows reports — including helpful graphs — to be automatically sent to them daily, weekly or whenever most useful. This feature is especially beneficial if engineers do not have access to the equipment being monitored.

Once you’ve configured your cDAQ hardware, project path and sensor channels in iTestSystem, set up your MultiDAQ and record a sample TDMS file. Then simply open Automated Analytics to set up and run a new automation. After that’s complete, configure Notifications Services on the schedule of your liking.

Rather than getting buried in a mountain of raw data files that require processing later, users can easily set up an automated routine using iTestSystem’s Automated Analytics feature and configure Notification Services to dispatch regular reports or only ping over when a system achieves any of countless thresholds.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.