Industrial Monitoring Tools: cRIO-9046 Embedded Controller

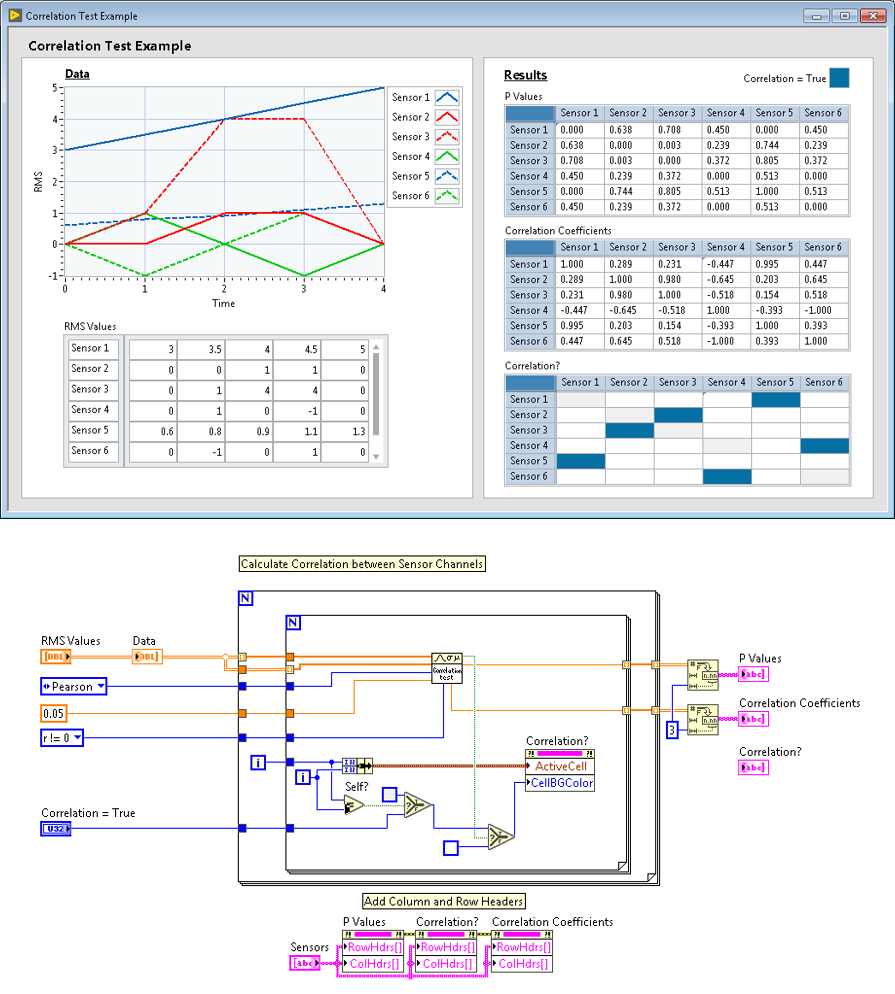

One of the tools our embedded software engineers commonly use for industrial control and process monitoring applications is the NI CompactRIO (cRIO) controller. These controllers let our engineers deploy autonomous systems that use complex algorithms to generate process outputs or key performance indicators (KPIs) from structural, vibration, and process monitoring sensors.

For example, in one of the latest industrial boiler monitoring applications, we embedded a cRIO-9046 controller with our Sootblower Fouling Detection (SFD) algorithms which are used to compute and then output equipment health and process efficiency KPIs. Let’s take a look at the cRIO-9046 controller’s specifications, functionality and programming.

cRIO-9046 is an 8-Slot CompactRIO Controller that has an Intel Atom 1.30 GHz Dual-Core CPU, 2 GB DRAM, 4 GB Storage, a Kintex-7 70T FPGA that can operate from -40 °C to 70 °C. The eight slots are used for C-Series conditioned IO modules that connect sensor inputs and data/control outputs and buses.

Its operating system, NI Linux Real-Time (64-bit), allows real-time performance with the usability desktop operating systems. Our engineers use Xilinx Kintex-7 7K70T FPGA to implement high-speed, (MHz) low-latency hardware-level data processing and decision-making. The cRIO-9046 also has several connectivity ports, including 2x Gigabit Ethernet, USB 3.1, USB 2.0, RS232, and RS485 ports.

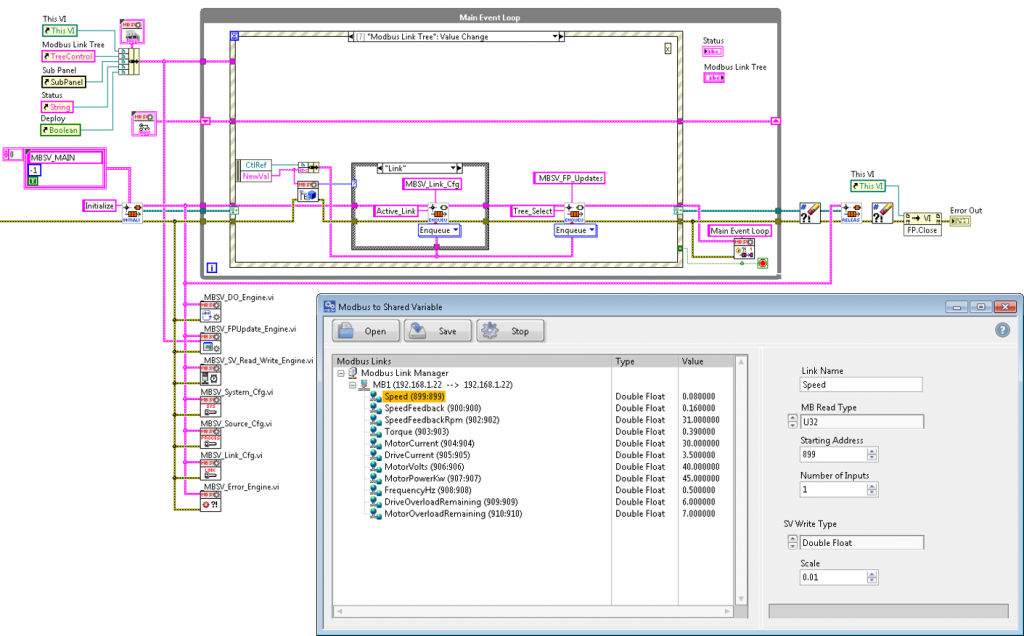

Embedded LabVIEW developers can use these ports and standard communication protocol toolkits to develop standard or custom machine/system interfaces.

For a cRIO-9046 or other CompactRIOs to operate, custom LabVIEW RT applications must be developed and then deployed to each controller. Depending on the complexity of your application, you may also need to develop and deploy LabVIEW FPGA code to the cRIO’s FPGA. Over the years, our embedded software engineers have developed a standard architecture as well as software tools for communication and analysis routines to simplify the custom LabVIEW RT application development. They also have experience developing embedded LabVIEW FPGA code for advanced hardware-level signal processing.

For more information about the cRIO-9046 and our LabVIEW development capabilities, contact Mark Yeager via email at mark.yeager@itestsystem.com

Related Links

This week we added another module to the iTestSystem compatibility list.

This week we added another module to the iTestSystem compatibility list.