Process Optimization with Embedded Monitoring Systems

Finding efficiency improvements and uncovering hidden unsafe conditions in a process can prevent injury and save your company millions.

The Energy category contains Case studies and blogs related to ITM’s energy engineering services.

Finding efficiency improvements and uncovering hidden unsafe conditions in a process can prevent injury and save your company millions.

ITM stake holders, we have recently received good news from the US Patent Office. They have recently allowed claims relating to the use of vibration measuring devices to evaluate the operation of a sootblower (US20190041201A1). This allowance strengthens the protection of the sootblower health and fouling detection features of ITM’s Sootblower Fouling Detection (SFD) Technology.

Additional Claims: “A method of evaluating an operation of a sootblower in a boiler system, the method comprising: operating a sootblower having a rotating lance tube; measuring a vibration in the boiler system caused by the operation of the sootblower, wherein the vibration is measured with a vibration measuring device; and analyzing the measured vibration to evaluate the operation of the sootblower.”

US Patent #: US20190041201A1

For more information about ITM’s SFD Technology or other Boiler Monitoring Systems, contact Ryan Welker @ (844) 837-8797 x702

Related Links

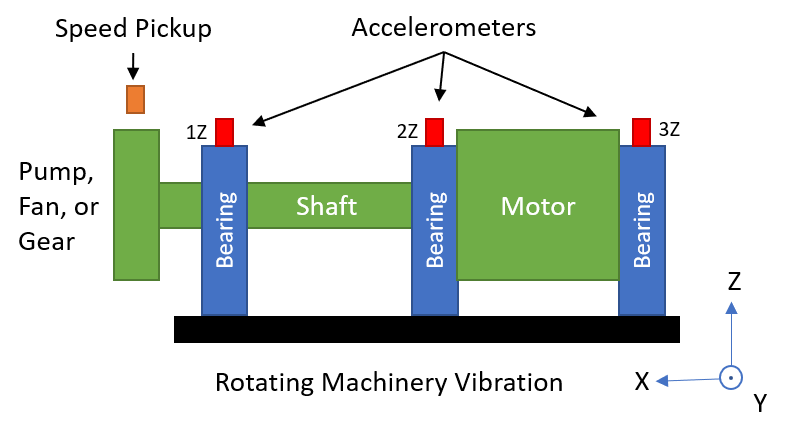

Choosing an accelerometer for rotating machinery vibration measurements can be a daunting task since there are so many options available. This blog outlines the characteristics you should consider when choosing a piezoelectric single axis accelerometer for general purpose vibration measurements and presents some accelerometers to consider.

When measuring vibration on rotating equipment such as motors, pumps, and generators, the most common measurement location(s) are on the shaft bearing housing(s) at the shaft centerline. At this location, typical vibration levels perpendicular to the shaft are < 100 g and the frequency range of interest is < 5000 Hz. A general purpose single axis piezoelectric accelerometer with either a 10 mV/g or 100 mV/g sensitivity fits this criteria.

Other characteristics to consider are size, mounting options, cable connections, grounding, and cost. Several mounting options are available. They include magnetic bases, adhesive bases and stud mounts. The mounting option you choose affects the frequency range of your accelerometer measurements. The table below shows typical frequency limits for accelerometer mounting methods.

| Mount Type | Typical Frequency Limit |

| Magnet | 2,000 Hz |

| Adhesive | 5,000 Hz |

| Stud | 6,000 Hz |

The table below shows some examples of stud mounted general purpose piezoelectric accelerometers. These accelerometers all have a female 10-32 coaxial / microdot connector. It is important to note that this is not a complete list of accelerometers and there are many options available from each manufacturer. I would encourage you to go to the websites linked in the table and see what’s available.

|

|

|

|

|

|

| Manufacturer | PCB | Dytran | BRÜEL & KJÆR | Endevco | Kistler |

| Model # | 353B03 | 3055D1 | 4533-B | 256HX -10 | 8702B500-M1 |

| Sensitivity | 10 mV/g | 10 mV/g | 9.8 mV/g | 10 mV/g | 10 mV/g |

| Frequency Range | (±5%) 1 to 7000 Hz | (±5%) 1 to 5000 Hz | (±10%) 0.2 – 12800 Hz | (±10%) 1 to 10000 Hz | (±5%) 1-10000 Hz |

| Temperature Range | -65 to +250 °F | -67 to +250 °F | –67 to +257 °F | -67˚F to +257˚F | -67˚F to +257˚F |

| Height | 0.88 in | 0.64 in | 0.54 in | 0.55 in | 0.67 in |

| Weight | 0.38 oz | 0.35 oz | 0.3 oz | 0.14 oz | 0.32 oz |

| Housing Material | Titanium | Titanium | Titanium | Titanium | Titanium |

| Electrical Connector | 10-32 Coaxial (side) | 10-32 Coaxial (side) | 10–32 Coaxial (side) | 10–32 Coaxial (top) | 10–32 Coaxial (side) |

| Mounting Thread | 10-32 Female | 10-32 Female | 10-32 Female | 10-32 Female | 10-32 Female |

For more information about collecting vibration data, accelerometers, iTestSystem, or test equipment rental, contact Mark Yeager @ (844) 837-8797 x701.

We would like to thank the Black Liquor Recovery Boiler Advisory Committee (BLRBAC) for allowing us to present our patented Sootblower Fouling Detection (SFD) technology at the Spring 2019 meeting in Atlanta, GA. SFD is ITM’s patented technology for measuring fouling/slagging along the path of an active sootblower in recovery and utility boilers.

During this presentation, Tim Carlier described the original SFD concept, the system’s Key Performance Indicator (KPI) outputs for closed or open loop control, and the system’s potential sootblower steam savings of 1-4% MCR. He also highlighted the safety and maintenance benefits that the system provides.

For more information about the SFD technology or to schedule an online presentation or site visit to audit your specific application, contact Tim Carlier or Ryan Welker.

Tim Carlier, President, tim.carlier@itestsystem.com, 513.608.4811

Ryan Welker, Business Development Manager, ryan.welker@itestsystem.com, 513.405.0181

Integrated Test & Measurement (ITM) is presenting its patented Sootblower Fouling Detection (SFD) technology at the Spring 2019 Black Liquor Recovery Boiler Advisory Committee (BLRBAC) meeting in Atlanta, GA on Wednesday, April 10, 2019.

ITM’s SFD system effectively offers the following benefits to boiler operations:

Find out more about ITM’s Sootblower Fouling Detection (SFD) system and other Boiler Monitoring Solutions at https://itestsystem.com/solutions/industrial-monitoring-systems/

Conference details can be found at http://blrbac.org/meeting-registration

Have questions? Contact Tim Carlier @ Tim.Carlier@iTestSystem.com

The tool we most commonly use for real-time embedded process monitoring and control applications is the NI CompactRIO. These controllers allow us to embed algorithms that acquire and analyze high speed process sensor data and then output derived key performance indicators (KPIs) to other control systems. Most of the time, our customers also require us to send the KPIs to a real-time data infrastructure like OSIsoft’s PI System so plant managers and engineers can use the data to find energy savings, monitor asset health, or optimize processes.

For our latest CompactRIO systems we have developed APIs that allow us to send or receive data directly to/from PI. We utilize the PI Asset Framework and the UFL Connector to automatically generate PI tags from the device and update the process tag values either on value change or on a time basis.

These tools greatly simplify our CompactRIO to PI System communication process by eliminating intermediary data servers and automatically generating PI tags based on a CompactRIO system’s configuration. If you are interested in using these APIs for PI or developing a CompactRIO system contact Mark Yeager or Chase Petzinger.

The US patent office has recently awarded patents to ITM for (2) two of the underlying boiler safety and process optimization technologies embedded within our CDS and SHOP systems. These systems monitor boiler conditions and alert operators when boiler tube damaging events/conditions occur.

Clinker Detection System (CDS) – US Patent 10060688B2

The Clinker Detection System (CDS) measures the relative weight, location, and frequency of clinkers that impact a boiler floor. This technology enables operators to shorten boiler outages, identify fouling problems, optimize soot blower operations and identify damaging impact events.

Superheater OverHeat Protection (SHOP) – US Patent 9541282B2

Superheater OverHeat Protection (SHOP) – US Patent 9541282B2

The Superheater OverHeat Protection (SHOP) system helps mitigate the risk of superheater tube failure due to short-term overheat during boiler start-ups. Catastrophic thin-lipped bursts can occur in superheater steam generation tubes when steam flow is insufficient, when deposits restrict flow, or when tubes are blocked by water due to a rapid firing rate during boiler start-up. SHOP assists operators in the management of boiler start-ups by enabling the detection of superheater tube clear events (TCE’s).

If you’re interested in learning more about these systems and other boiler/process monitoring solutions, feel free to contact Ryan Welker by e-mail at ryan.welker@itestsystem.com or phone at (844) 837-8797.

Check out my article “Putting a HALT to Hazardous Hopper Maintenance” in the May 2018 edition of Power Magazine. This article describes a system for detecting dangerous plugging conditions inside ash hoppers. Ash hoppers are used in the power industry to collect hot ash from utility boilers. – Mark Yeager

Follow the link below for the on-line version.

https://www.powermag.com/putting-a-halt-to-hazardous-hopper-maintenance

For more information about a Halt System or our other Boiler Monitoring Systems contact Ryan Welker @ (844) 837-8797 x702

Check out the article “Increase the IQ of Your Intelligent Sootblowing” by my colleague Mark Yeager in the December edition of Power Magazine. In this article, Mark describes ITM’s Sootblower Fouling Detection (SFD) technology which allows for targeted sootblowing, by pinpointing exactly when and where sootblowing is required in chemical recovery and coal-fired power boilers.

https://www.powermag.com/increase-the-iq-of-your-intelligent-sootblowing

ITM’s president Tim Carlier (tim.carlier@iTestSystem.com) is presenting its Superheater Overheat Protection (SHOP) technology at the Spring 2017 Black Liquor Recovery Boiler Advisory Committee (BLRBAC) Meeting in Atlanta, GA on April 12th. SHOP helps boiler operators avoid short term overheat failures of recovery boiler superheater tubes.

ITM’s president Tim Carlier (tim.carlier@iTestSystem.com) is presenting its Superheater Overheat Protection (SHOP) technology at the Spring 2017 Black Liquor Recovery Boiler Advisory Committee (BLRBAC) Meeting in Atlanta, GA on April 12th. SHOP helps boiler operators avoid short term overheat failures of recovery boiler superheater tubes.

ITM will also introduce new boiler and plant optimization technologies/systems that their partners have used to streamline processes.

Conference details can be found at http://www.blrbac.org/

Find out more about ITM’s Boiler Monitoring Solutions /solutions/industrial-monitoring-systems/

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.