Lattice Boom Crane Structural Design Validation

A case study describing a strain gauge DAQ system used to validate several new designs of a heavy lift lattice boom crane to comply with SAE J987 standards.

A case study describing a strain gauge DAQ system used to validate several new designs of a heavy lift lattice boom crane to comply with SAE J987 standards.

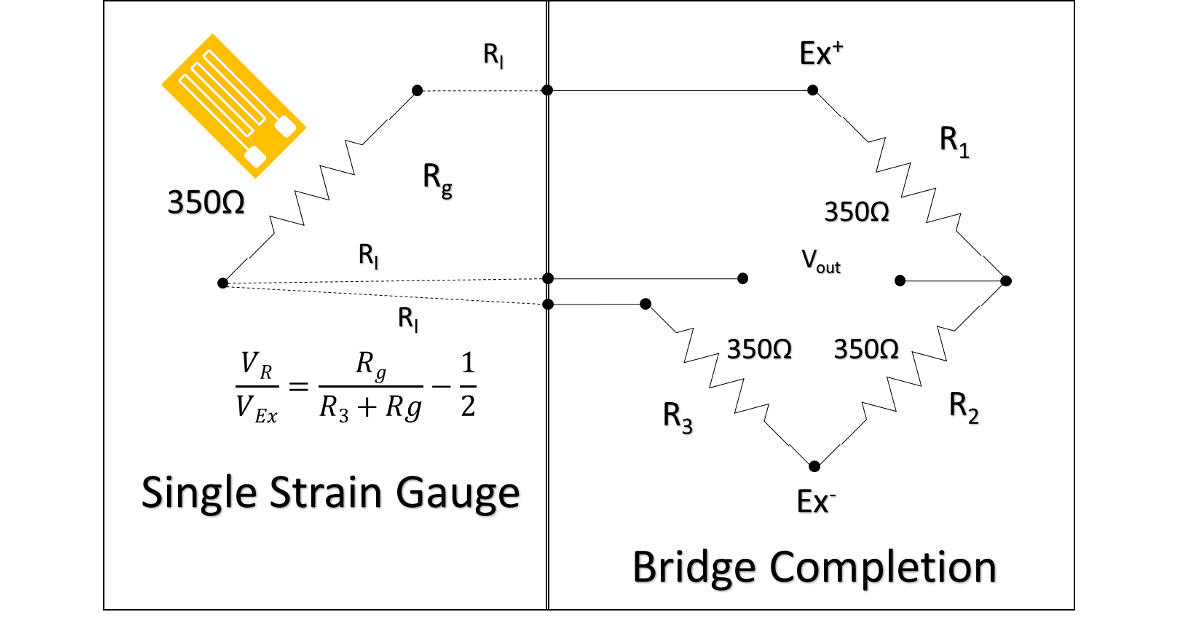

Quarter Strain Bridge with Completion Circuit

The most common strain gauges used to quantify the state of stress on a test specimen’s surface, are uniaxial and rosette gauges. For accurate measurements of stress and strain, these uniaxial and rosette gauges are independently connected as a Wheatstone bridge in a 3-wire quarter-bridge or half-bridge arrangement.

Strain Gauge Installations for Field Testing | Strain Gauge Services | tshirt-Strain Gauge Services Rectangular Rosette | Engineering Data Acquisition Tools: NI-9237 Bridge Input Module

Custom PTO Shaft Strain Gauge Transducer by ITM | Custom Strain Transducer Service | Custom Strain Gauge Measures KitchenAid Shaft Load

Today, most high-end data acquisition equipment manufacturers provide signal conditioning options for collecting data from single strain gauges. Signal conditioning for strain gauges usually includes circuitry for bridge excitation voltage, quarter and half bridge completion arrangements, and shunt calibration.

Are you looking for expert assistance with accurately measuring stress and strain? or, Do you need to rent or buy data acquisition equipment to collect stress and strain data?

Sometimes you may need to view or collect data from a single strain gauge using a device that only has analog voltage inputs and no strain signal conditioning. This was precisely the case when I was working with the HX711 load cell/strain amplifier. The HX711 requires a full bridge input so I instrumented my test specimens as such. If I needed to use a single strain gauge with the HX711, I would have had to use an external bridge completion circuit.

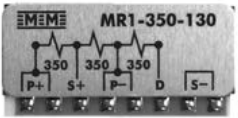

Option 1: Buy a commercial off the shelf bridge completion modules.

The list below gives the specifications for some available bridge completion modules. I plan on adding more completion modules to this list for future reference, so send me any additional completion options.

|

|

|

|

| Manufacturer | NI | VPG | Campbell Scientific |

| Model # | NI 9926, NI 9945, NI 9944 | MR1-10C-129, MR1-350-130, MR1-120-133 | 4WFBS1K, 4WFBS350, 4WFBS120 |

| Description | 3-Wire Quarter Bridge Completion | 3-Wire Quarter Bridge Completion | 3-Wire Quarter Bridge Completion |

| Resistance | 1000 Ω, 350 Ω, 120 Ω | 1000 Ω, 350 Ω, 120 Ω | 1000 Ω, 350 Ω, 120 Ω |

| Strain Gauge Connector | Terminal Block | Solder Tab | Terminal Block |

| Device Connector | RJ50 | Solder Tab | Pins and Lead Wire |

Option 2: Build your own circuit.

If you are building a product or are in the strain business long term, building your own circuit may be a cost effective alternative to the potentially more expensive off the shelf bridge completion option. I have built a few bridge completion circuits in the past. Here is a list of things to keep in mind when designing a circuit.

For more information about bridge completion or our strain gauging services, contact Ryan Welker @ (844) 837-8797 x701.

Related Links

Strain Gauge Installations for Field Testing

iTestSystem Tip: Strain Gauge Rosette Analysis

Wireless Strain Measurements with iTestSystem, LabVIEW, and Arduino

When troubleshooting structural failures or validating FEA models through testing, strain gauge rosettes are used to find the full state of strain at areas of concern around the structure. iTestSystem’s Rosette Analysis tool is used to calculate the principal strain, principal strain angle, shear strain, principal stress, and other values from strain gauge rosette data. This video shows how to use the Rosette analysis tool.

For questions about using the Rosette Analysis tool or other iTestSystem analysis tools contact Chase Petzinger.

Download your free version of iTestSystem today.

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.