High Channel Count Synchronous Datalogging

From edge to AWS cloud, ITM’s iTestSystem turns massive datalogging into actionable KPIs, enabling operators to monitor usage and structural health instantly.

From edge to AWS cloud, ITM’s iTestSystem turns massive datalogging into actionable KPIs, enabling operators to monitor usage and structural health instantly.

Modern Tools Series: What’s In The Box?

This box reveal may not be quite as dramatic as the ending of “Seven,” the ’95 serial killer thriller that blew moviegoers’ minds, but the ITM team is throwing open the latches nonetheless.

In this case, our team is taking you on a quick tour of a recently deployed Rugged Data Acquisition System. These particular black boxes of tech are riding around on high-dollar fracking equipment to remotely monitor all sorts of triggering events. Our crew builds them on the regular, and the end result is that our clients can better understand what sorts of stress, strain and vibration is taking place both en-route to their site and once operations begin.

ITM is known for building rugged measurement systems and data logging solutions that are deployed on everything from Class A trucks, to well frac trailers, to dam and bridge structures, oil pipelines, gensets, boilers and more.

So, without further ado, what’s in the box?

We recommend a handful of essential components and elements if you are looking to build your own rugged measurement system:

So there you have it. That’s what’s in the box. Build your own, or get in touch with our team, and we’ll customize a system for your specific needs.

We also install and service all of our equipment. So if something breaks in the field, we can get you back up and collecting data or even assist with data analysis.

For more information about our rugged data acquisition systems, on-site system deployment or data analysis services, contact Josh Fishback via email at josh.fishback@itestsystem.com or phone at (844) 837-8797 x705.

Concrete Science: ITM Applying Modern Methods to Study Civil Structures

ITM has spent the last two decades testing the limits of steel, aluminum, composites, and other materials. From the heights of space to the depths of underground mines, our team has improved the art of using strain gauges to measure stress on metal, machines and complex systems. As the Milford, Ohio, firm enters its third decade, ITM engineers have returned to the lab to demonstrate some of the methods to measure rebar reinforced concrete using strain gauge technologies.

Concrete literally holds together much of our modern world, yet, many of our civil structures built in the mid-20th century are crumbling. From bridges to buildings, concrete is cracking and failing at an alarming rate, yet few are applying modern engineering methods to measure and monitor this foundational material we all rely upon.

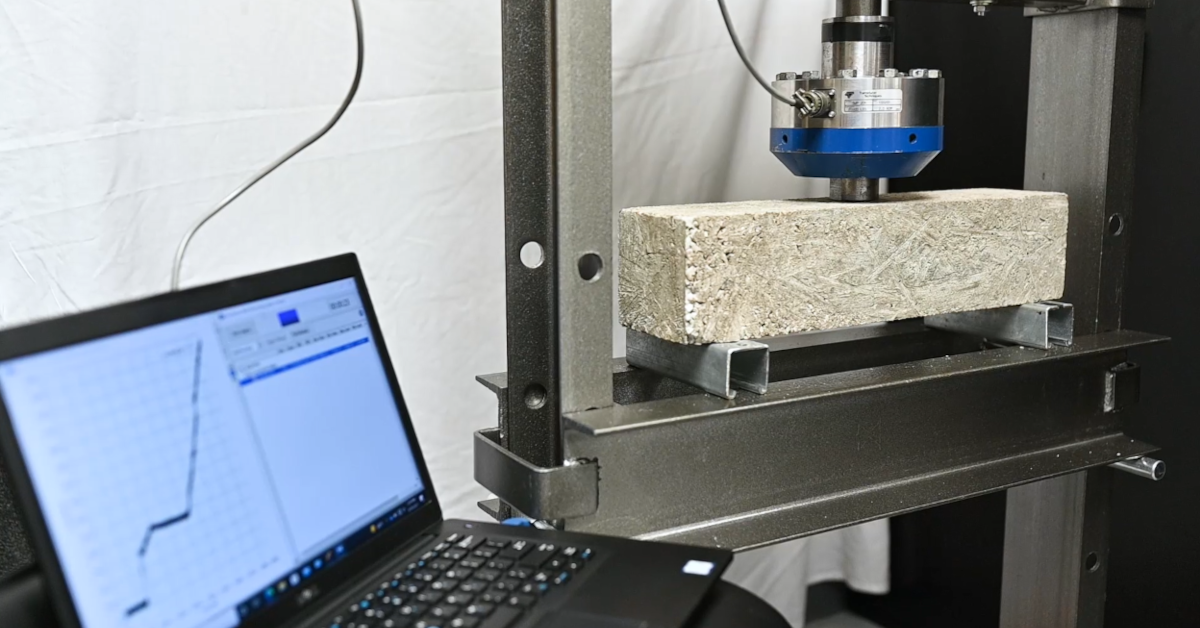

As part of recent experiments, ITM staffers crafted test materials into mini concrete beams to illustrate how the materials hold up under stress and, more importantly, what it takes to capture the data. In our lab we placed 4-inch square by 18-inch long concrete beams under several thousand pounds of load using a hydraulic press. Gauges were affixed not only on the outside of the beams but also embedded inside the beam along the rebar used to reinforce the concrete. We used a laptop running our iTestSystem Software, an NI cDAQ-9171 Chassis, and NI-9236 modules to capture data from the strain gauges installed on the concrete specimens.

The data captured as the beams were brought to failure revealed the superiority of certain sensor bonding materials and methods during the testing. Importantly, it also showed that the stress along the internal rebar and that of the gauges on the outside of the concrete beams remained in sync as evidenced by the graphs that reveal the stress data.

Our team will continue these studies to show various methods currently being used to measure stress & strain in concrete structures and concrete crack propagation, the importance of which is only reinforced by news of deadly building collapses and aging civil structures. Stay tuned for more blogs detailing our findings and best practices for using today’s technology to measure structural concrete cracking.

For more information on this work, our testing services or iTestSystem, contact: Ryan Welker – Integrated Test & Measurement (ITM), LLC – ryan.welker@itestsystem.com

Coming Soon! iTestSystem 20.0

When: January 2022

The latest version of ITM’s engineering measurement software platform will make gathering data easier and more affordable than ever.

For more information about iTestSystem, contact Chase Petzinger at (844) 837-8797 x704 or via email at chase.petzinger@itestsystem.com.

The students and advisors huddled around the computer react as they watch the signal yield an immediate spike within ITM’s iTestSystem software…

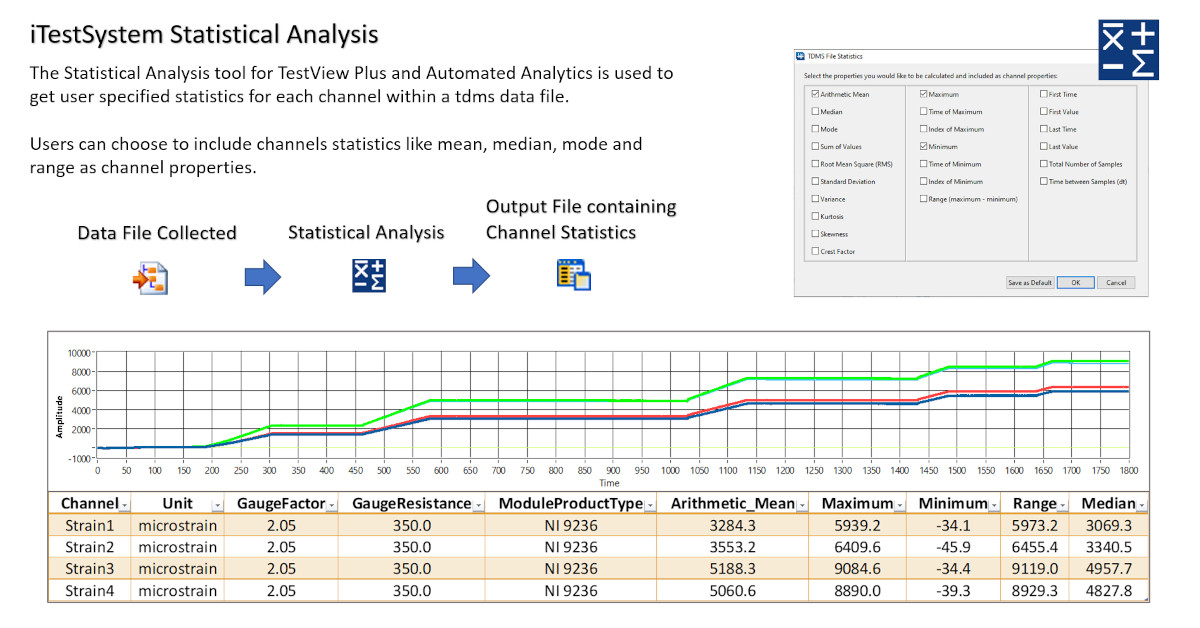

Quickly Identify Significant Events in Large Data Sets with Statistical Analysis

Use statistical analysis for TestView Plus and Automated Analytics to extract statistics like minimum, maximum, and mean from each sensor. The results of the selectable analysis is embedded within the data file as searchable meta data.

Automated Analytics users can quickly identify data files within large data sets that contain sensor events of interest. When paired with Trigger Analysis and the Notification Service, these data files can be automatically selected and sent via email in remote monitoring applications.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with NI cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.