As the global market moves steadily in the direction of increased productivity through integration of software into the world of testing services, Integrated Test & Measurement finds itself at the forefront of the field. Our other LabVIEW developers and I have been hard at work creating custom applications to help customers meet their testing needs with more efficiency and cost-effectiveness than ever before.

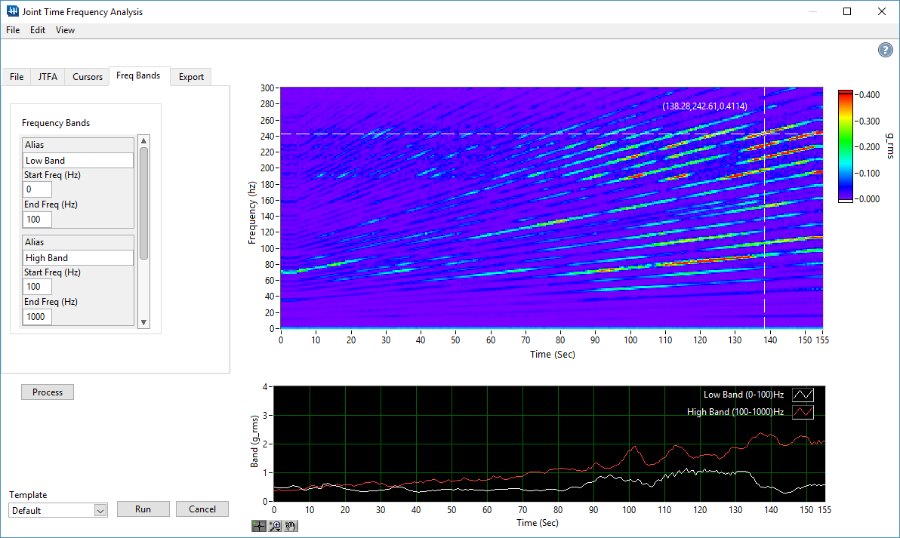

Since many of my co-workers come from both test engineering and software development backgrounds, it’s easier for us to scope, build, and deploy these custom testing applications while working hand-in-hand with on-site operators and field engineers, or even sending our own engineers on-site to test the applications. Past projects I’ve gotten to work on have ranged from a small data collection and viewing application that allows a customer to perform materials testing and quickly generate reports; to larger systems like a power quality application which utilizes our iTestSystem platform and allows the customer to collect and perform real time power-quality analysis on large genset engines, view and quickly confirm results, and create multiple types of reports for both internal and external customers.

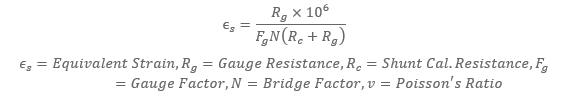

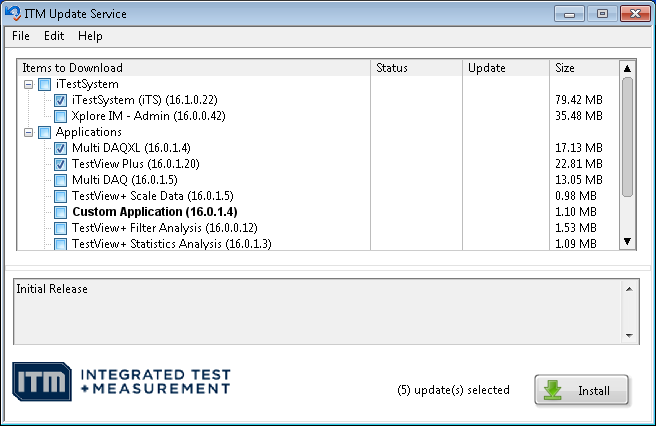

Thanks to ITM’s iTestSystem platform, we have been able to leverage our pre-existing data acquisition, data viewing, and application distribution tools to create and distribute these applications both faster and at lower price points than many of our customers expected. Having this base platform allows me to create and test solutions quickly and to make revisions with ease. As a LabVIEW developer on Team ITM, I have enjoyed the unique challenges presented in these applications and look forward to seeing how ITM continues to lead the field in this market.

Contact Information: For more information about our LabVIEW application development service contact:

Mark Yeager – Integrated Test & Measurement (ITM), LLC. Email: mark.yeager@itestsystem.com or Phone: 1.844.TestSys