Pulp & Paper

The Pulp & Paper category contains Case studies and blogs related to pulp & paper engineering services.

Predictive Maintenance with Amazon Monitron Sensors

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Energy, Engineering Services Posts, Off-Highway, Power Generation, Pulp & Paper/by Mark YeagerStrain Gauges Improve Cooling Tower Fan Performance

in Blog Posts, Civil | Infrastructure, Energy, Power Generation, Pulp & Paper, Strain Gauge Services/by Mark YeagerITM connects with future engineers at UC Career Fair

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Construction | Mining, Energy, Off-Highway, Power Generation, Pulp & Paper/by Mark Yeager

ITM connects with future engineers at UC Career Fair

Mixed among the buzz of voices inside the massive six-court gymnasium at the University of Cincinnati Technical Career Fair this week, ITM connected with a ton of impressive engineering students.

Potential full-time employees and co-op students heard for the first time about our engineering firm in Milford, Ohio. It is always a joy to watch their eyes light up as we share the projects our team has the opportunity to deploy across the country and around the world.

The aerospace students hear that we work on rockets. The mechanical engineering students learn of the rugged measurements we collect on massive machinery. And the computer programmers discover that we’ve spun up our own software products.

The reaction is almost always the same: “Wow! I had no idea.”

For our team, the day is equally as fulfilling as we connect with the next generation of engineers eager to get to work and apply their knowledge.

Our firm is interested in filling full-time roles for students graduating with a degree in mechanical engineering, mechanical engineering technology, electrical engineering, electrical engineering technology and aerospace engineering.

Are you a current student or recent graduate who loves adventure, travel and has an entrepreneurial spirit? Discover a culture driven by innovation at ITM. Check out our job postings or fill out our co-op questionnaire (/jobs/).

Come Visit our Booth at the UC Career Fair

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Construction | Mining, Energy, Off-Highway, Power Generation, Pulp & Paper/by Mark Yeager

Looking for a new career? Come visit us at the University of Cincinnati Career Fair!

Where: UC Rec Center, Booth G18

When: Sept. 15th, 2022 – 10AM – 2 PM

For more information about available jobs, contact Josh Fishback via email: josh.fishback@itestsystem.com or phone: (844) 837-8797.

ITM Recruiting Full-Time Engineers at UC’s Fall Career Fair

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Energy, Off-Highway, Power Generation, Pulp & Paper/by Mark Yeager

ITM Recruiting Full-Time Engineers at UC’s Fall Career Fair

University of Cincinnati students have an enormous opportunity to make a career-changing connection during the Professional and Technical Career Fair on Thursday, September 15.

Integrated Test & Measurement (ITM) will host a booth during Technical Day 2 of the event at UC’s Campus Recreation Center. Interested students can find ITM representatives from 10 a.m. to 3 p.m.

Our firm is interested in filling full-time roles for students graduating with a degree in mechanical engineering, mechanical engineering technology, electrical engineering, electrical engineering technology and aerospace engineering.

In addition to seeking full-time hires, we are searching for talented students who are interested in experiencing a dynamic and fulfilling co-op opportunity where you will have a chance to learn through exciting, hands-on engineering projects around the country.

ITM is a structural test & measurement engineering service and software company in Milford, Ohio, that focuses on three vertical spaces: Industrial Monitoring, Testing Services, and our configuration based test software, iTestSystem.

ITM offers competitive compensation and benefits and a career filled with travel and new learning opportunities. ITM was founded by Tim Carlier in 2001 to help companies around the world reduce costs and improve efficiencies in their product development, manufacturing and production activities.

Interested candidates should stop by our booth inside UC’s Campus Recreation Center from10 a.m. to 3 p.m. on Thursday Sept. 15 and/or email a resume and cover letter to: josh.fishback@itestsystem.com.

Our team will also be drawing for free hats and T-shirts, so be sure to find us during the event to learn more about ITM.

Rockets, road trips and paper mills

in Aerospace | Defense, Blog Posts, Power Generation, Pulp & Paper/by Ryan Welker

Why an ITM team trekked across Alabama several times in the same week

Our team should be intimately familiar with the three-hour stretch of I-65 between Prattville and Decatur, Alabama. They drove it four times in about as many days during a recent work trip.

The team had been on a troubleshooting assignment to a rocket-building NASA partner that needed help with what appeared to be failing sensors. They had no idea that what seemed like a fairly straightforward trip would soon become far more interesting and logistically challenging. One phone call later though, and they were dispatched 166 miles south to a paper mill client.

Upon arrival, they began commissioning new Acosense technology on the plant’s process lines. Integrated Test & Measurement is an exclusive U.S. installer of the Swedish technology that can constantly monitor and analyze liquids inside a pipe with non-invasive clamp-on sensors.

The small crew proved themselves both flexible and adaptable by pulling double duty as they served both clients for the better part of a week. Rocket work one day. Back in the car. Paper mill the next. Back in the car. And so on until both jobs were complete. The week could serve as a microcosm of the variety of work ITM engineers balance regularly.

“That was a challenging week for this crew for sure,” said ITM President Tim Carlier. “But it was all interesting technology and gave the team a chance to troubleshoot newer equipment. So it was a good learning challenge for us and an example of our dedication to meet the needs of our clients.”

ITM engineers and technicians experience a wide variety of projects and travel opportunities. For some, the real joy is working with their hands on site, while others prefer the more technical activities such as computer assisted design or relying on their social skills during customer interactions.

Ultimately, we do what it takes to deliver — even when that means burning up the roads in Alabama to get the job done.

For more information about our strain gauging and testing services contact Ryan Welker @ (844) 837-8797.

ITM Co-op Helps Engineering Student Set Sights Even Higher

in Aerospace | Defense, Blog Posts, Civil | Infrastructure, Energy, Off-Highway, Power Generation, Pulp & Paper/by Ryan Welker

ITM Co-op Helps Engineering Student Set Sights Even Higher

Tyler House’s dream career began to come into sharper focus during his spring co-op at Integrated Test & Measurement.

After four months at the Milford, Ohio, firm the University of Cincinnati electrical engineering student headed into his summer feeling both excited by his work experience and inspired to emulate ITM CEO Tim Carlier one day by starting his own company.

“I know I want to do something I love,” said Tyler, who had just returned from a trip to Disney with his girlfriend to celebrate the end of the semester. “I’d like to start my own company someday. I’ve been poking at that idea. Definitely a big dream of mine is having that freedom and doing something that means a lot to me.”

Perhaps the only thing that equals Tyler’s love of engineering is his love of music. He and a few fellow graduates from Clermont Northeastern (CNE) high school started a band called Wishbone, which has started lining up local gigs to cover rock and blues tunes stretching back a half century.

Tyler’s two worlds collided on the last day of his co-op when a couple of engineers from ITM dropped into his band’s “first bonafide show.”

“It was so much fun watching their reaction,” said Tyler, who employs his electrical engineering skills to repair the band’s gear when things inevitably break. “I love that they came.”

Coincidentally, like Wishbone, ITM’s entire leadership team — the CEO, VP of Operations, Lead Programmer and Administrative Director — are all CNE graduates. For Tyler, seeing that level of success from the same small high school as him was only more of a confidence lift.

He loves the entrepreneurial and inventive culture at ITM, where staff members are constantly tackling new challenges. “It’s really just a great place to figure out what you are into,” he said.

Tyler found himself learning a ton about Fusion 360, a cloud-based 3D modeling program, while researching mechanical properties and simulating failure modes on a bolted joint. He said he spent about half his co-op in the office doing things like assembling Data Acquisition (DAQ) boxes and the other half on the road working on-site. Experiences included everything from climbing inside massive paper mills to helping gather data on equipment operating in remote locations all over the country.

“In talking with my friends who have had co-ops, it’s hard to get to work in a place where you feel like you can make a difference and actually help fix problems,” said Tyler. “I definitely felt that. I learned really fast about how to deal with mistakes and just general problem solving.”

Besides the on-the-job learning, he loved exploring new places, national parks and more with the ITM crew after hours. He’s hoping to pick up some work helping ITM with any projects through the summer, and he’s interested in returning during his next co-op rotation in Spring of 2023.

Meanwhile, he’ll keep poking at his dream of someday owning his own company.

“You just have to go out there and get it,” Tyler said. “If you are aggressive about it, you will fail a bunch. But you’ve got to be able to get up off the ground and just keep rolling with it.”

For more information about Co-op or employment opportunities at ITM, contact Josh Fishback via email at josh.fishback@itestsystem.com or phone at (844) 837-8797 x705.

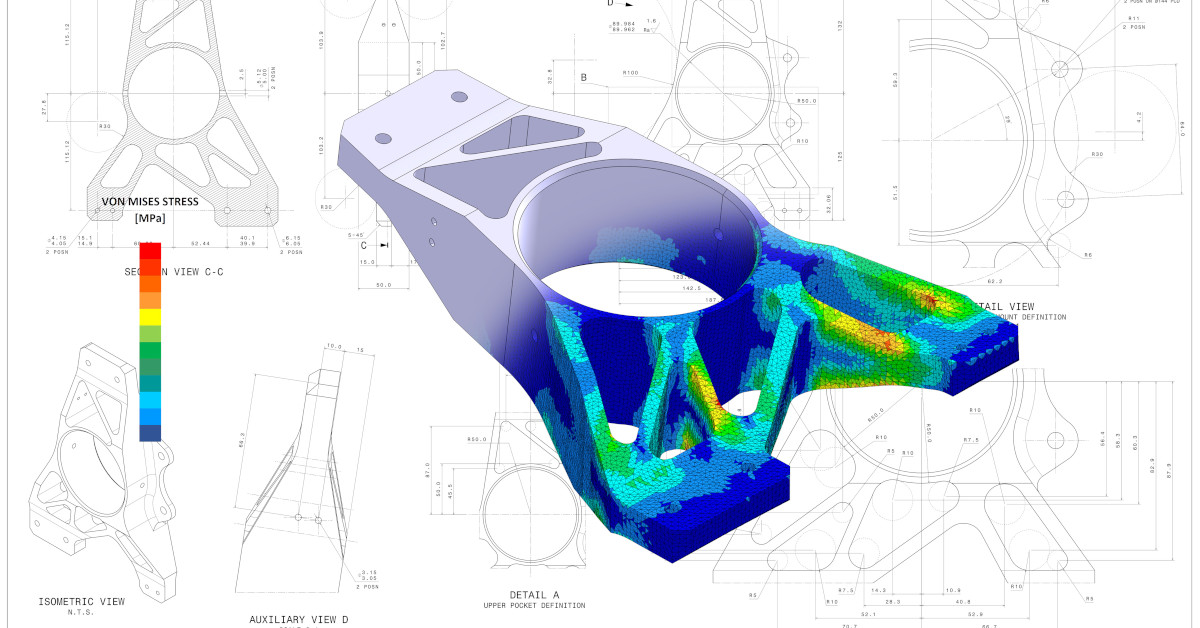

Endless Testing Options Through Finite Element Analysis (FEA)

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Construction | Mining, Energy, Off-Highway, Power Generation, Pulp & Paper/by Ryan Welker

Design Validation Finite Element Analysis (FEA) using strain gauge measurements.

Endless Testing Options Through Finite Element Analysis (FEA)

Whether our customers need us to validate their Finite Element Analysis (FEA) models or perform both the physical testing and the FEA, our engineers are used to helping customers with complex testing and analysis of high-value equipment.

As a recent example, our team is involved in a large-scale project to do engine testing for a client that requires ITM to do both the physical testing as well as the FEA simulations. This requires using a custom high-channel count telemetry system to transmit engine data to a receiver that is sampling at an extremely high rate.

“Once you are able to bring in the test data and compare it to the simulated data, you are able to fine tune your FEA simulation to better reflect the real-world application,” said ITM engineer Ryan Matthews. “We can also simulate the test in software and predict how it is going to react to the test when we can actually measure such things as strain, stress and vibration.”

Matthews points out that FEA technology also helps the team determine the precise best placement of strain gauge during physical testing. And depending on complexity, a single simulation can take a few seconds or months to run.

For obvious reasons — mainly the cost of bringing high-value assets to failure — running repeated strain gauge tests on components simply isn’t feasible, but ITM’s in-house capabilities and close partnership with sister firm SixDOF opens up endless FEA simulation options to clients.

“Sometimes you are only going to be able to test a structure or a part once before it fails,” says Matthews. “So it becomes crucial to do a limited number of physical tests then correlate that to your FEA. Then you can pretty much run unlimited simulations.”

For more information about our testing, strain gauging, and FEA modeling services contact Ryan Welker via email at ryan.welker@itestsystem.com of phone @ (844) 837-8797.

Going Old School to Deliver New Solutions

in Aerospace | Defense, Automotive, Blog Posts, Power Generation, Pulp & Paper/by Ryan Welker

High-tech measurement systems? Not a problem.

Complex data acquisition or custom software solutions? Right in our wheelhouse.

At ITM, these kinds of challenges have become commonplace in our lab, but one recent project that hit our doorstep stretched our engineers, and not for the reasons you may be thinking.

Our customer wanted an old-school manual operator control station. Think classic-style red and green, push-button start and stop controls, which they wanted to energize various parts of a large test cell for a military marine application.

The ask was a bit out of ITM’s typical range of services simply because most systems they develop don’t require manual control stations to run their equipment. Instead, their customers usually opt for computer-controlled testing, which ITM crafts regularly. Still, the job required a complete CAD design, a custom cabinet enclosure and hundreds of electrical components to be designed and assembled, which our team successfully delivered to the satisfaction of the client.

Modern Integration

The same customer also wanted to be able to collect complex data from the tests, and ITM, of course, delivered on this challenge as well thanks to its proprietary iTestSystem software, which computer engineer Chase Petzinger deployed to build a custom DAQ.

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view and analyze data from machinery, processes, vehicles and other complex rugged measurement systems. iTestSystem was specifically designed for use with NI cDAQ or FieldDAQ hardware for data collection and data logging, so it was no stretch to equip it to pull down data from the military equipment test.

In the end, the job required running new-school modern technology to handle the data collection and reporting simultaneously alongside the old-school analog operator control panel. From successfully assembling hundreds of electrical components to deploying custom software that can handle hundreds of channels of data from a wide variety of sensors at once, ITM truly showed its range on this project.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

CONTACT INFORMATION

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.