iTestSystem Applications

This category contains iTestSystem platform main applications for configuring sensor channels, as well as collecting, viewing, and analyzing data.

Enhance Your Data Analysis with Python in iTestSystem: A Comprehensive Guide

in Aerospace | Defense, Automotive, Blog Posts, Civil | Infrastructure, Energy, iTestSystem Analysis, LabVIEW Channel, Off-Highway, Pulp & Paper/by Mark YeagerIdentify Damaging Events with Statistical Analysis

in Blog Posts, iTestSystem Analysis/by Chase Petzinger

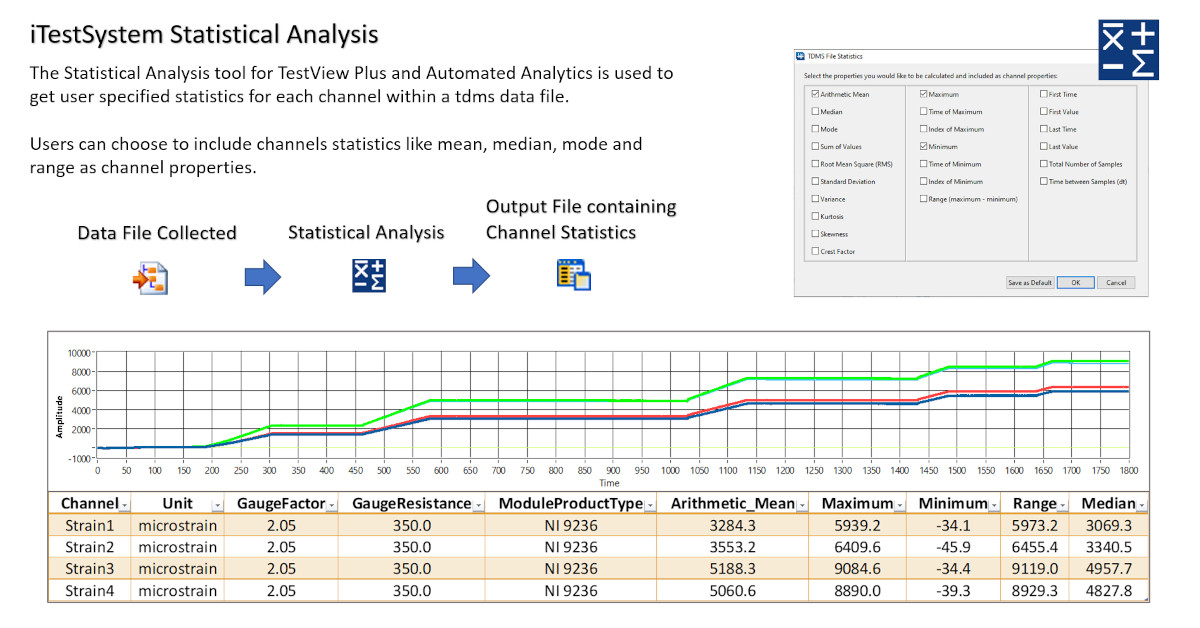

Quickly Identify Significant Events in Large Data Sets with Statistical Analysis

Use statistical analysis for TestView Plus and Automated Analytics to extract statistics like minimum, maximum, and mean from each sensor. The results of the selectable analysis is embedded within the data file as searchable meta data.

Automated Analytics users can quickly identify data files within large data sets that contain sensor events of interest. When paired with Trigger Analysis and the Notification Service, these data files can be automatically selected and sent via email in remote monitoring applications.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with NI cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

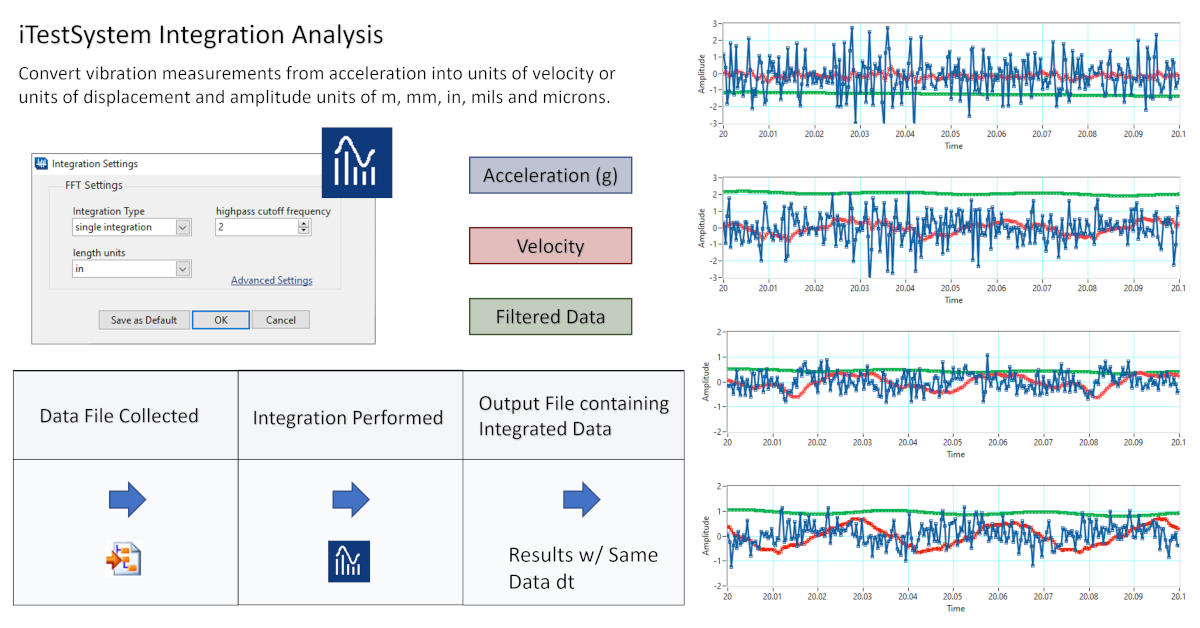

Vibration Data Integration Analysis

in Blog Posts, iTestSystem Analysis/by Chase Petzinger

Simplify Acceleration Conversions with iTestSystem’s Integration Analysis Tool

Like many features in iTestSystem, the Integration Analysis tool was created because customers requested it. After all, who doesn’t like features that make the math easier?

In this blog, a new series by ITM, we’ll share some details about Integration Analysis, one of the features within TestView Plus, the project based data viewing function within iTestSystem.

For engineers who are gathering vibration data, it makes perfect sense to have a simple way to convert acceleration into units of velocity or units of displacement since those are the most common specs.

Enter the Integration Analysis function. Simply open TestView Plus, drop down the “Analysis” tab and select “Integration.” Once there, adjust the settings to either “Single Integration” for velocity or “Double Integration” for displacement. In a couple of additional clicks, you can also specify your desired units and adjust the high cutoff frequency to filter low frequency data.

The next time you are gathering data using accelerometers, let iTestSystem simplify all those conversions with Integration Analysis.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

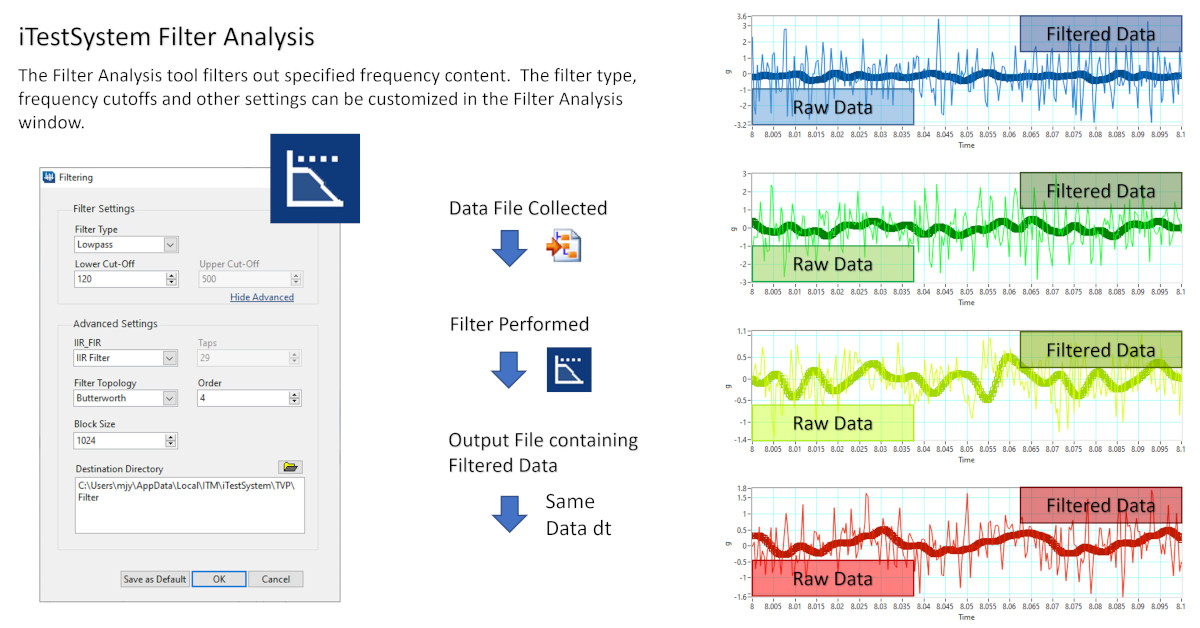

Weed Out Unwanted Data with Filter Analysis

in Blog Posts, iTestSystem Analysis/by Chase PetzingerFor engineers, the faster one can weed out the noise, the more efficiently one can deliver actual solutions.

The software architects at Integrated Test & Measurement have added new plugin technology to iTestSystem, their proprietary engineering measurement software platform, to enhance the user experience by allowing users to analyze data faster by filtering frequencies simply.

In this blog, a new series by ITM, we’ll share some details about one of the features within TestView Plus, the project based data viewing function within iTestSystem.

Once you’ve configured your test using NI MultiDAQ hardware and begun logging strain gauge and accelerometer data, it is time to do an FFT (fast Fourier transform) Analysis to further analyze your signals for frequency information to learn how the system you are testing is actually vibrating.

As part of that process, the Filter Analysis plugin allows users to filter out unwanted frequencies — say anything over 100 Hz — which only requires checking a simple low-pass filter option, a tool embedded right within TestView Plus.

Without leaving TestView Plus, you can simply choose which signals you wish to view, configure a few options on the screen and click the FFT button to output helpful data files for your report or plot directly within TestView Plus to begin isolating specific vibration issues.

Stay tuned for additional iTestSystem features.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

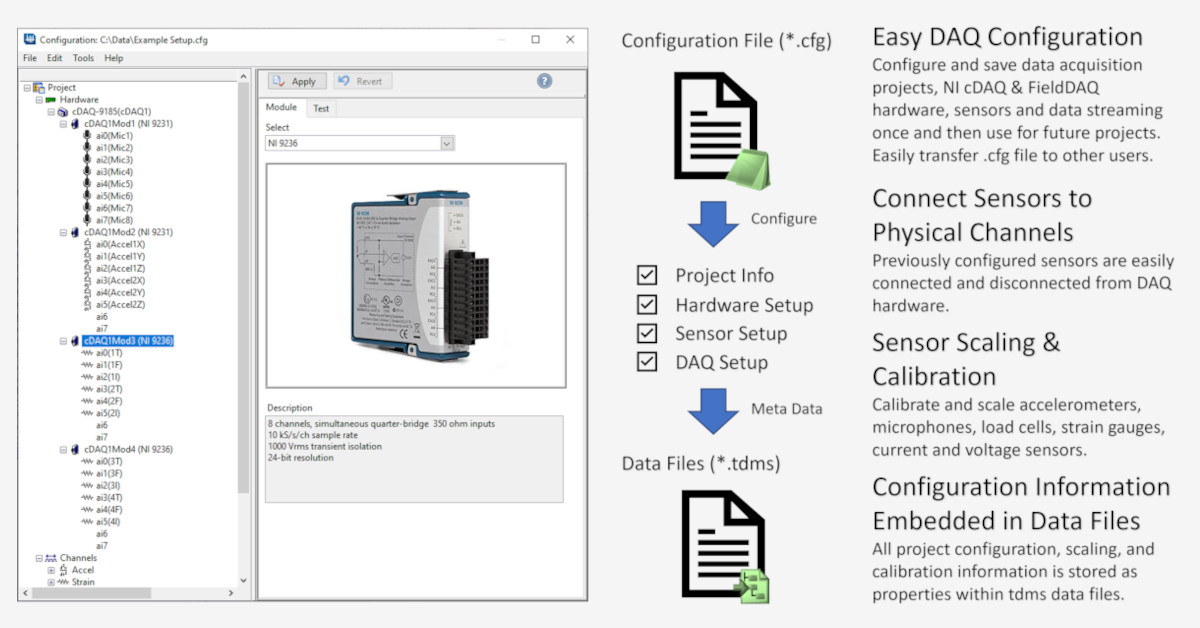

iTestSystem Application: Configuration

in Blog Posts, iTestSystem Application/by Mark Yeager

Turn Weeks Into Hours with iTestSystem’s Configuration Feature

If you are like most engineers, the last thing you want to do is spend hours upon hours configuring your project, your hardware and your sensors before gathering important data.

The team at Integrated Test & Measurement (ITM) has been there. In fact, they grew so tired of repeating all those monotonous configurations when setting up NI cDAQ and NI FieldDAQ hardware that they built their own custom software known as iTestSystem to simplify the experience.

In this blog, a new series by ITM, we’ll share details about Configuration, the core feature of iTestSystem and a driving reason their software engineers first dreamed it up clear back in 2007.

Imagine opening a single screen to set up your entire test — from the hardware you are using to all the sensors you are employing to how you are planning to take the data. With iTestSystem’s Configuration feature these things are not only possible, they are reusable. In other words, you set up your hardware and configure your channels once, and all future applications can reuse the same setup.

iTestSystem users are used to heading to the Configuration screen not just to set up their MultiDAQ tests but also to calibrate, zero and test their sensors to be sure everything is working and connected correctly prior to going into a test. It is also a simple way to preview all your channels.

Managing tests has never been easier, even when taking thousands of channels of data. You can even save and share your test setup with others. And, best of all, iTestSystem is a free download, so anyone can take advantage of the massive time savings — turning weeks of work into hours of work.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with NI cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

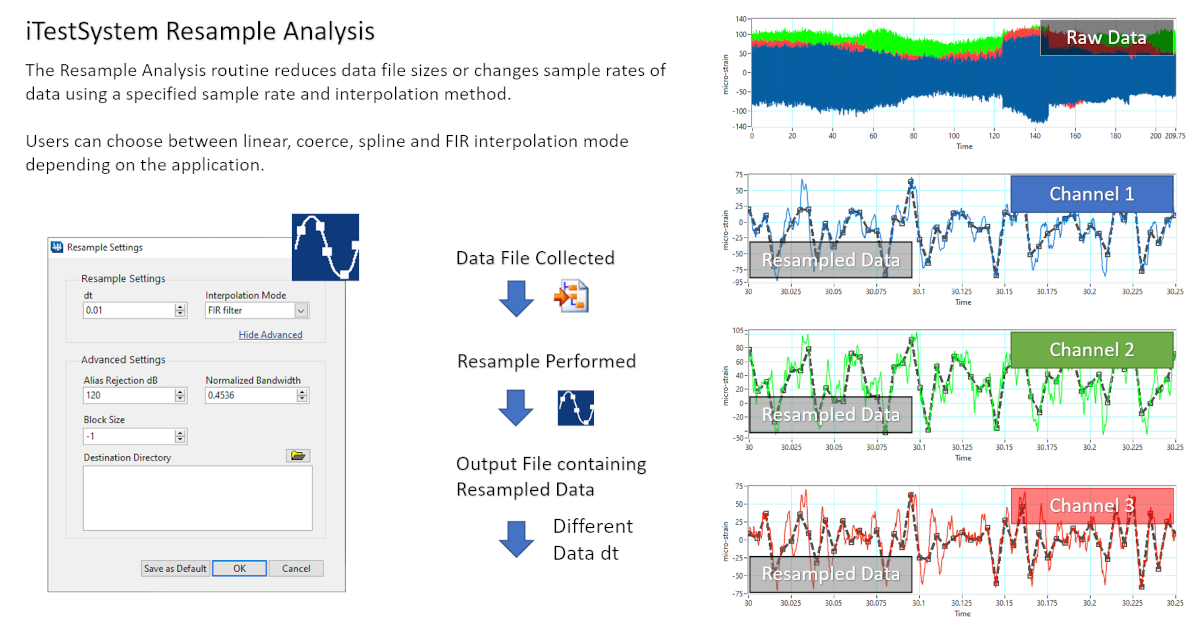

Reduce File Size with Resample Analysis

in Blog Posts, iTestSystem Analysis/by Mark Yeager

Going Small Can Yield Big Results Thanks to Resample Analysis Feature

While it may seem counterintuitive to those used to gathering massive data files to solve complex engineering challenges, certain situations actually require gathering smaller files if you want to run a successful test.

For example, certain tests require gathering data on remote machinery over multiple months. In that instance, the onboard hard drive that’s storing the data will simply run out of space if you are gathering data at a high sample rate.

The team at Integrated Test and Measurement anticipated such needs. In this blog, a new series by ITM, we’ll share some details about Resample Analysis, one of the features within TestView Plus, the project based data viewing function within iTestSystem.

Though simple, the Resample Analysis function allows you to perform a powerful function — to greatly reduce file sizes while maintaining an accurate picture of the information gathered. With one click, raw files that were saving at 20 MB and larger are reduced to less than 1 MB, yet your engineers will still be able to capture an accurate picture of the test.

The process is easy. Open TestView Plus, add a channel, plot some data and click the Resample feature, just remember to also use the Filtering feature to avoid aliasing your data. Though you are sacrificing frequency content, you are gaining data storage, and the data will still tell you the big picture of what’s happening.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

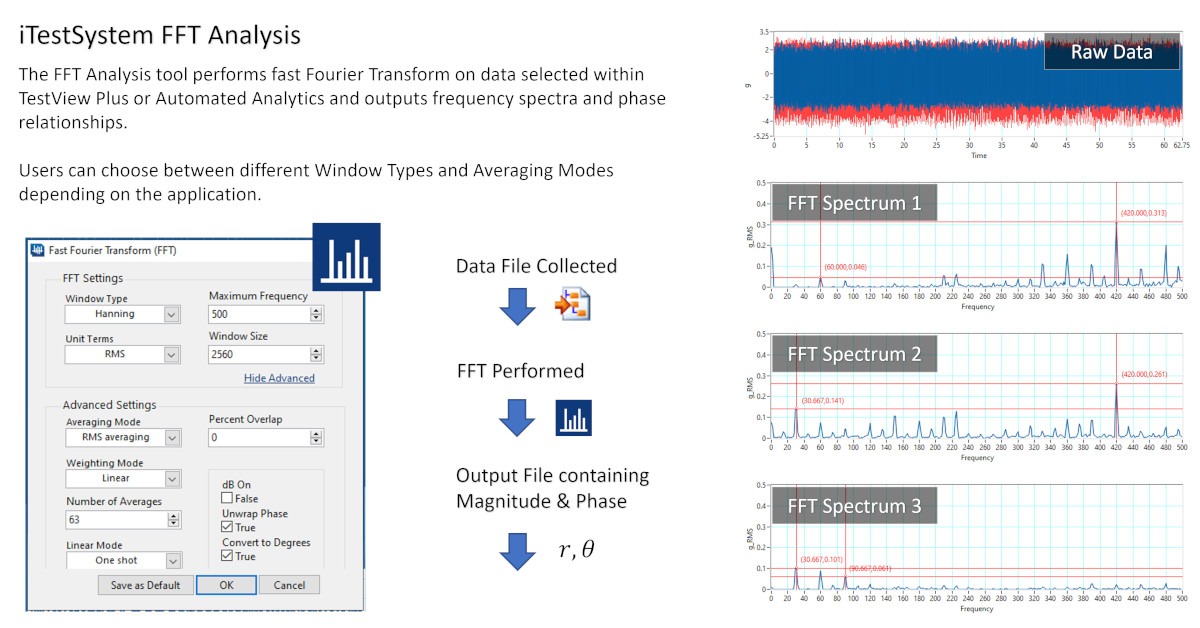

Use FFT Analysis in iTestSystem to Pinpoint Vibration Issues

in Blog Posts, iTestSystem Analysis/by Mark Yeager

Simplifying Process for FFT Analysis using iTestSystem to Pinpoint Vibration Issues

The software engineers at Integrate Test & Measurement are constantly looking for ways to enhance and simplify your experience using iTestSystem, their proprietary engineering measurement software platform.

In this blog, a new series by ITM, we’ll share some details about one of the features within TestView Plus, the project based data viewing function within iTestSystem.

Are you one who tires of gathering vibration data in one tool then having to port it over to a whole separate tool to analyze the signal data? Thanks to plugin functionality in the latest version of iTestSystem, you can now manage both functions all from the same screen.

Once you’ve configured your test using NI MultiDAQ hardware and begun logging strain gauge and accelerometer data, it is time to do FFT (fast Fourier transform) Analysis to further analyze your signals for frequency information to learn how the system you are testing is actually vibrating. Without leaving TestView Plus, you can simply choose which signals you wish to view, configure a few options on the screen and click the convenient FFT button to output helpful data files for your report or plot directly within TestView Plus to begin isolating specific vibration issues.

Stay tuned for additional iTestSystem features, including a plugin that allows Filter Analysis to quickly weed out unwanted frequencies.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ or FieldDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

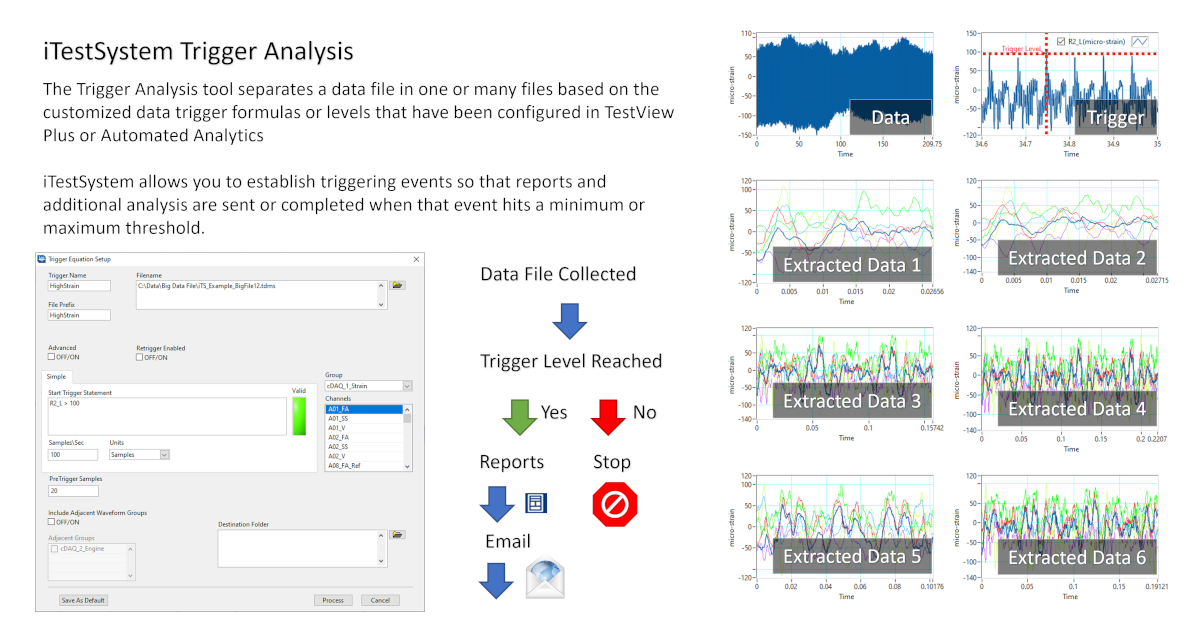

Sort Data Faster Using iTestSystem’s Trigger Analysis

in Blog Posts, iTestSystem Analysis/by Mark Yeager

Sort Your Engineering Data Faster Using iTestSystem’s Trigger Analysis Feature

Tired of getting buried in a mountain of engineering data? The team at Integrated Test & Measurement feels your pain, and they have built some relief into their data collection software known as iTestSystem.

In this blog, a new series by ITM, we’ll share details about iTestSystem’s “Trigger Analysis” feature, which is commonly used to help analyze, sort and pass crucial engineering data — think strain and vibration — to those who need it most and just in time.

The Trigger Analysis tool separates a data file in one or many files based on the customized data trigger(s) that have been configured, and that’s a feature that saves engineers countless hours.

Here’s how Trigger Analysis works:

If you are an engineer attempting to gather data from a piece of machinery, vehicle or complex system, iTestSystem allows you to establish triggering events so that reports are only sent when that event hits a minimum or maximum threshold. For example, if you know a damaging event occurs at a certain threshold, you can easily set iTestSystem to only report information or graphs to you when an accelerometer goes over a maximum level or when an engine passes a set RPM.

In other words, the software is gathering data constantly, but it only sends the data when it matches a specific threshold.

By configuring Trigger Analysis along with both Notification Services and the Automated Analytics features in iTestSystem, engineers are able to greatly simplify processes that require hunting down system operation outliers or damaging events. These iTestSystem applications allow users to analyze, build, and send sensor level reports only when specific vibration and strain limits are exceeded. In the end, that leads to a massive time savings. Instead of searching through streams of data files, engineers can easily review the report and download relevant data files from deployed systems for further analysis.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

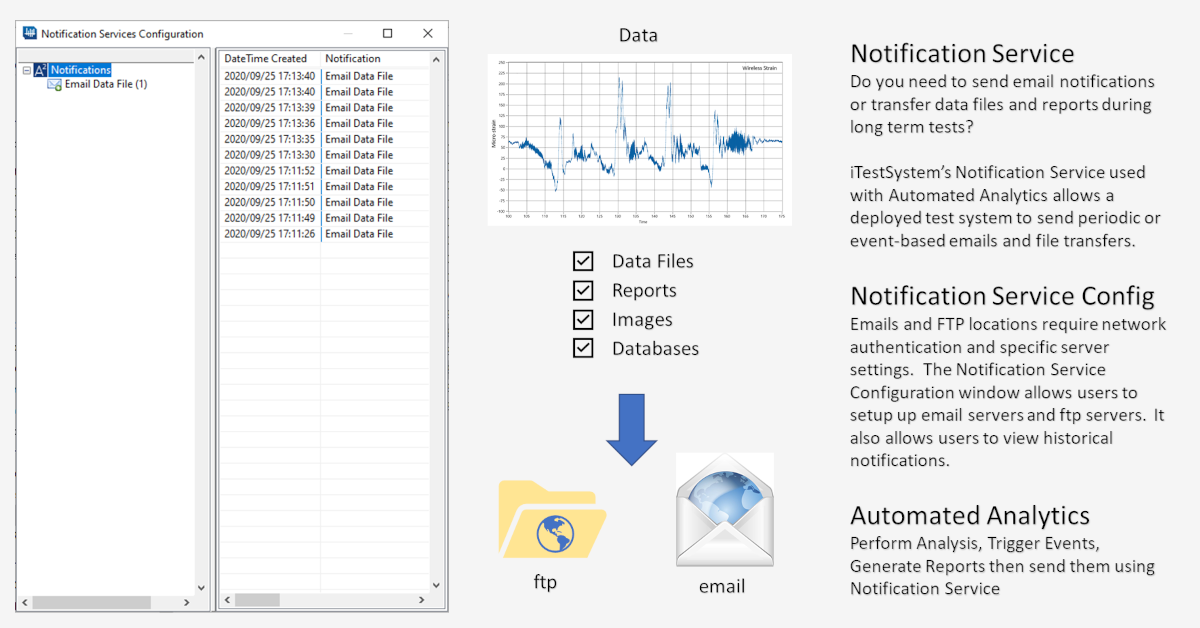

iTestSystem Application: Notification Service

in Blog Posts, iTestSystem Services/by Mark Yeager

Get Your Engineering Data When it Counts using ITM’s iTestSystem Software

In a world where we’ve grown accustomed to knowing about important events or crucial information nearly immediately, it may be of little surprise that the architects who build engineering measurement software included powerful notification abilities.

An Amazon package delivery to your doorstep now prompts an email, a text or even a blinking light on your Alexa or Google Assistant.

At Integrated Test & Measurement, the engineers behind iTestSystem applied this need-to-know concept to the latest version of their powerful and proprietary data-collection tool. In this blog, a new series by ITM, we’ll share details about iTestSystem’s “Notification Services” feature, which is commonly used to to pass crucial engineering data — think strain and vibration — to those who need it most and just in time.

By pairing Notification Services with the Automated Analytics feature in iTestSystem, engineers are able to greatly simplify processes that require hunting down system operation outliers or damaging events. The Automated Analytics application allows users to analyze, build, and send sensor level reports only when specific vibration and strain limits are exceeded. In the end, that leads to a massive time savings. Instead of searching through streams of data files, engineers can easily review the report and download relevant data files from deployed systems for further analysis.

Does your project involve the need to deploy unattended or “black box” data acquisition systems in the field? If so, iTestSystem may be the ideal solution.

Here’s how Notification Services works:

As mentioned above, users can pair the Automated Analytics feature with the power of Notification Services, an iTestSystem feature that allows reports — including helpful graphs — to be automatically sent to them daily, weekly or whenever most useful. This feature is especially beneficial if engineers do not have access to the equipment being monitored.

Once you’ve configured your cDAQ hardware, project path and sensor channels in iTestSystem, set up your MultiDAQ and record a sample TDMS file. Then simply open Automated Analytics to set up and run a new automation. After that’s complete, configure Notifications Services on the schedule of your liking.

Rather than getting buried in a mountain of raw data files that require processing later, users can easily set up an automated routine using iTestSystem’s Automated Analytics feature and configure Notification Services to dispatch regular reports or only ping over when a system achieves any of countless thresholds.

About iTestSystem

iTestSystem is an engineering measurement software platform that enables test engineers to organize, acquire, view, and analyze data from machinery, processes, vehicles and other complex systems. iTestSystem was specifically designed for use with National Instruments (NI) cDAQ hardware for data collection and data logging.

For more information about our iTestSystem or ITM’s testing services, contact Ryan Welker @ (844) 837-8797 x702.

CONTACT INFORMATION

ITM | Integrated Test + Measurement

227 Water Street, Suite 300

Milford, OH 45150

Phone: 1.844.TestSys

Fax: 513.248.8453

Email: ITM Sales

ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. ITM is a recognized National Instruments Gold Alliance Partner.